16 16 Hoag, C., Spradling, D., & Shulman, H. (2012). Introduction to additive manufacturing of ceramics (pp. 15). Ceramic Industry.

17 17 Compton, B. G., & Lewis, J. A. (2014). 3D‐printing of lightweight cellular composites. Advanced Materials, 26, 5930–5935.

18 18 Castles, F., Isakov, D., Lui, A., Lei, Q., Dancer, C. E. J., Wang, Y., . . . Grant, P. S. (2016). Microwave dielectric characterisation of 3D‐printed BaTiO3/ABS polymer composites. Scientific Reports, 6, 22714.

19 19 Scheithauer, U., Weingarten, S., Johne, R., Schwarzer, E., Abel, J., Richter, H.‐J., . . . Michaelis, A. (2017). Ceramic‐based 4D components: Additive manufacturing (AM) of ceramic‐based functionally graded materials (FGM) by thermoplastic 3D printing (T3DP). Materials, 10, 1368.

20 20 Cui, H., Hensleigh, R., Yao, D., Maurya, D., Kumar, P., Kang, M. G., . . . Zheng, X. R. (2019). Three‐dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nature Materials, 18, 234–241.

21 21 Kim, H., Renteria‐Marquez, A., Islam, M. D., Chavez, L. A., Rosales, C. A. G., Ahsan, M. A., . . . Lin, Y. (2019). Fabrication of bulk piezoelectric and dielectric BaTiO3 ceramics using paste extrusión 3D printing technique. Journal of the American Ceramic Society, 102, 3685–3694.

22 22 Masciandaro, S., Torrell, M., Leone, P., & Tarancón, A. (2019). Three‐dimensional printed yttria‐stabilized zirconia self‐supported electrolytes for solid oxide fuel cell applications. Journal of the European Ceramic Society, 39, 9–16.

23 23 McOwen, D. W., Xu, S., Gong, Y., Wen, Y., Godbey, G. L., Gritton, J. E., . . . Wachsman, E. D. (2018). 3D‐printing electrolytes for solid‐state batteries. Advanced Materials, 30, 1707132.

24 24 Esposito, V., Gadea, C., Hjelm, J., Marani, D., Hu, Q., Agersted, K., . . . Jensen, S. H. (2015). Fabrication of thin yttria‐stabilized‐zirconia dense electrolyte layers by inkjet printing for high performing solid oxide fuel cells. Journal of Power Sources, 273, 89.

25 25 Sukeshini, A. M., Cummins, R., Reitz, T. L., & Miller, R. M. (2009). Inkjet printing of anode supported SOFC: Comparison of slurry pasted cathode and printed cathode. Electrochemical and Solid‐State Letters, 12, B176.

26 26 Sun, K., Wei, T. S., Ahn, B. Y., Seo, J. Y., Dillon, S. J., & Lewis, J. A. (2013). 3D printing of interdigitated Li‐Ion microbattery architectures. Advanced Materials, 25, 4539.

27 27 Ahn, B. Y., Duoss, E. B., Motala, M. J., Guo, X., Park, S., Xiong, Y., . . . Lewis, J. A. (2009). Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science, 323, 1590.

28 28 van Dijk, L., Paetzold, U. W., Blab, G. A., Schropp, R. E. I., & Di Vece, M. (2016). 3D‐printed external light trap for solar cells. Progress in Photovoltaics, 24, 623.

29 29 Pesce, A., Hornés, A., Núñez, M., Morata, A., Torrell, M., & Tarancón, A. (2020). 3D printing the next generation of enhanced solid oxide fuel and electrolysis cells. Journal of Materials Chemistry A, 8, 16926–16932.

30 30 de Hazan, Y. (2012). Robotic deposition of 3D nanocomposite and ceramic fiber architectures via UV curable colloidal inks. Journal of the European Ceramic Society, 32, 1187.

31 31 Stuecker, J. N. (2004). Advanced support structures for enhanced catalytic activity. Industrial and Engineering Chemistry Research, 43, 51.

32 32 Van Noyen, J. (2011). Catalyst design with porous functional structures. WIT Transactions on Ecology and the Environment, 154, 93.

33 33 Scheffler, M., & Colombo, P. (Eds.) (2005). Heterogeneously catalyzed processes with porous cellular ceramic monoliths (Chapter 5.4). In Cellular ceramics: Structure, manufacturing, properties and applications (pp. 454). Weinheim: Wiley‐VCH GmbH.

34 34 Dautzenberg, F. M., & Mukherjee, M. (2001). Process intensification using multifunctional reactors. Chemical Engineering Science, 56, 251.

Part I 3D printing of functional materials

1 Additive Manufacturing of Functional Metals

Venkata Karthik Nadimpalli and David Bue Pedersen

Department of Mechanical Engineering, Technical University of Denmark, Kgs. Lyngby, Denmark

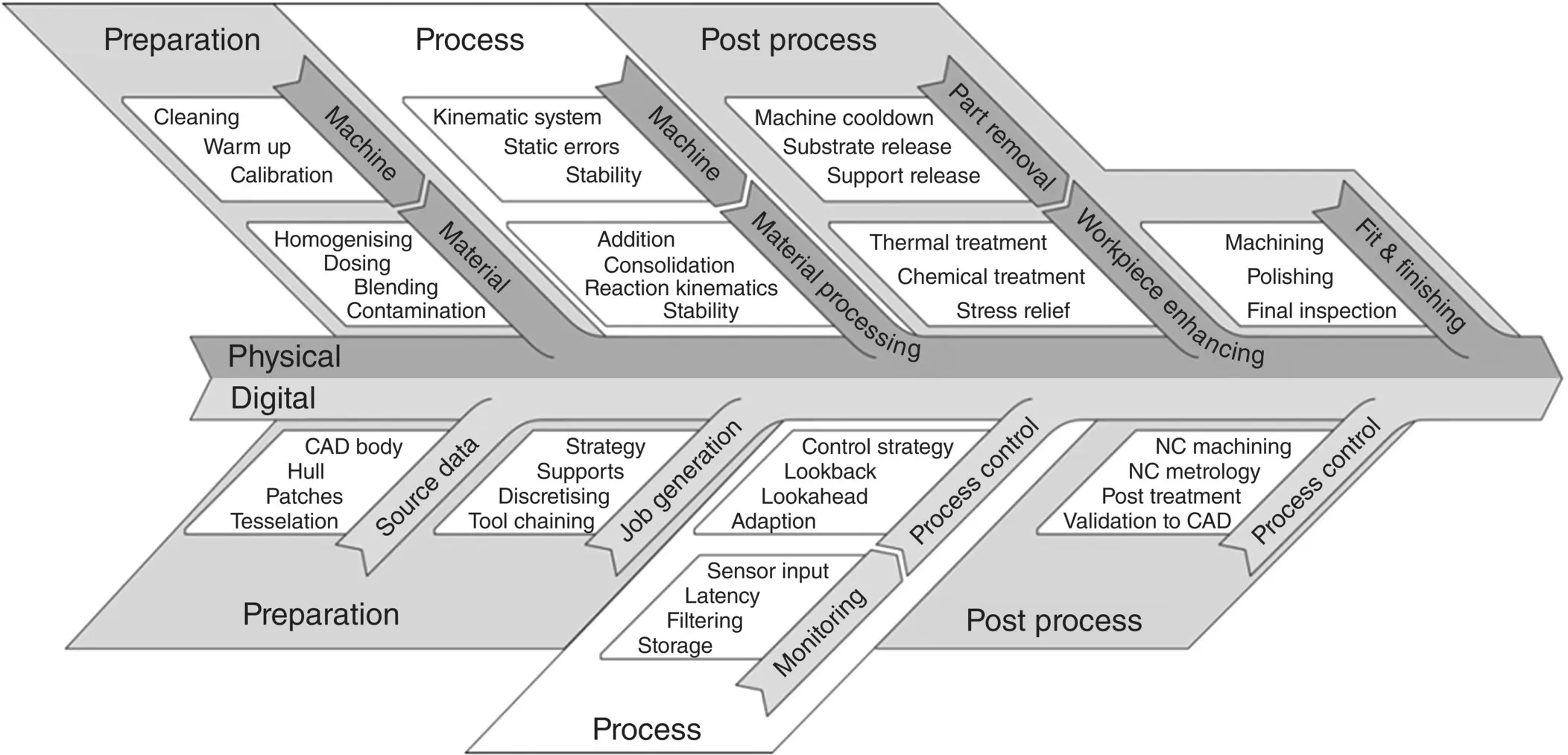

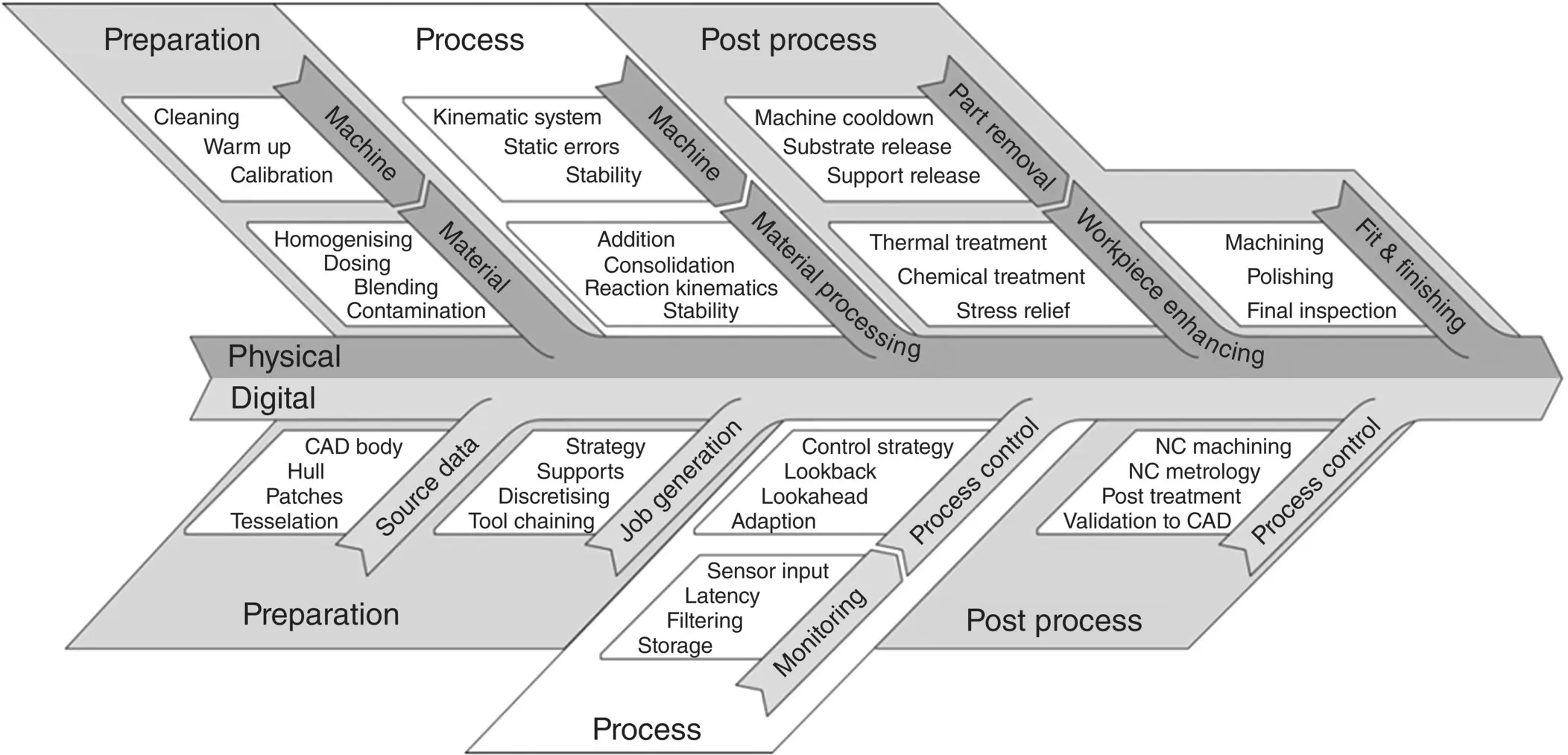

Additive manufacturing (AM) technologies [1, 2] comprise a family of manufacturing methods that colloquially are known by the common appellation of “3D Printing.” AM has created a strong linkage between digital and physical manufacturing, thus nourishing by its nature, a wider trend, digitization, and the automation of the manufacturing industry. For this reason, the increasing adoption of AM within the manufacturing industry is pushing companies to research new ways of adapting their manufacturing models and optimize their manufacturing strategies by integrating these manufacturing technologies of tomorrow into existing production and bolster their strategies toward a digital to physical conversion [3]. To illustrate the digital to the physical linkage of AM, Figure 1.1serves as an overview of the gross elements for a generic AM process.

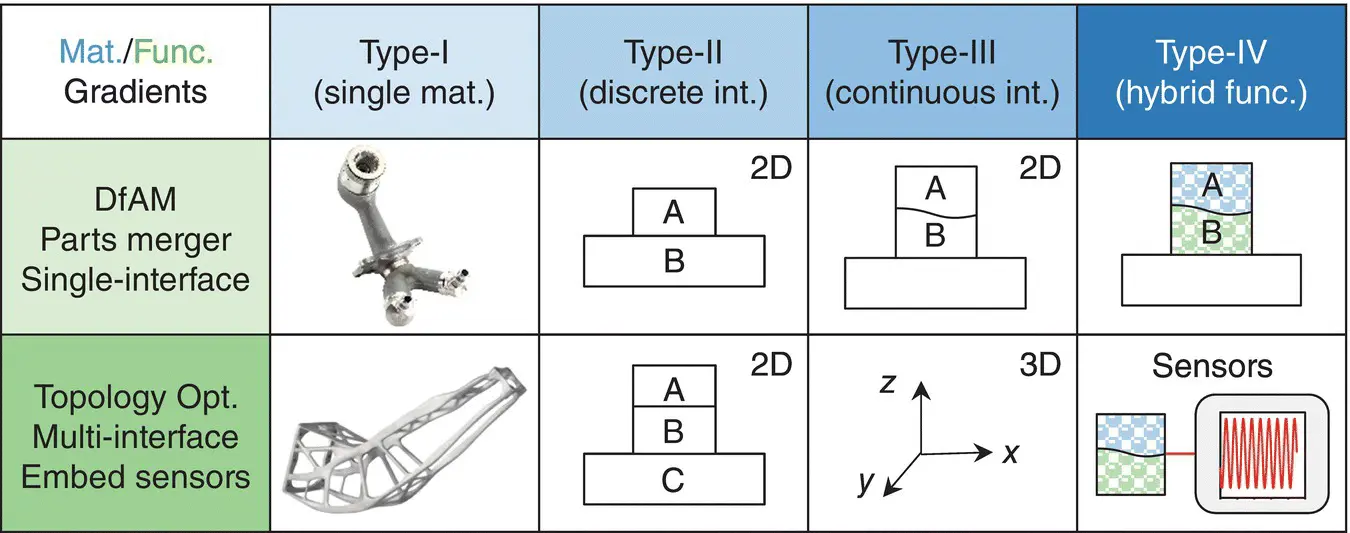

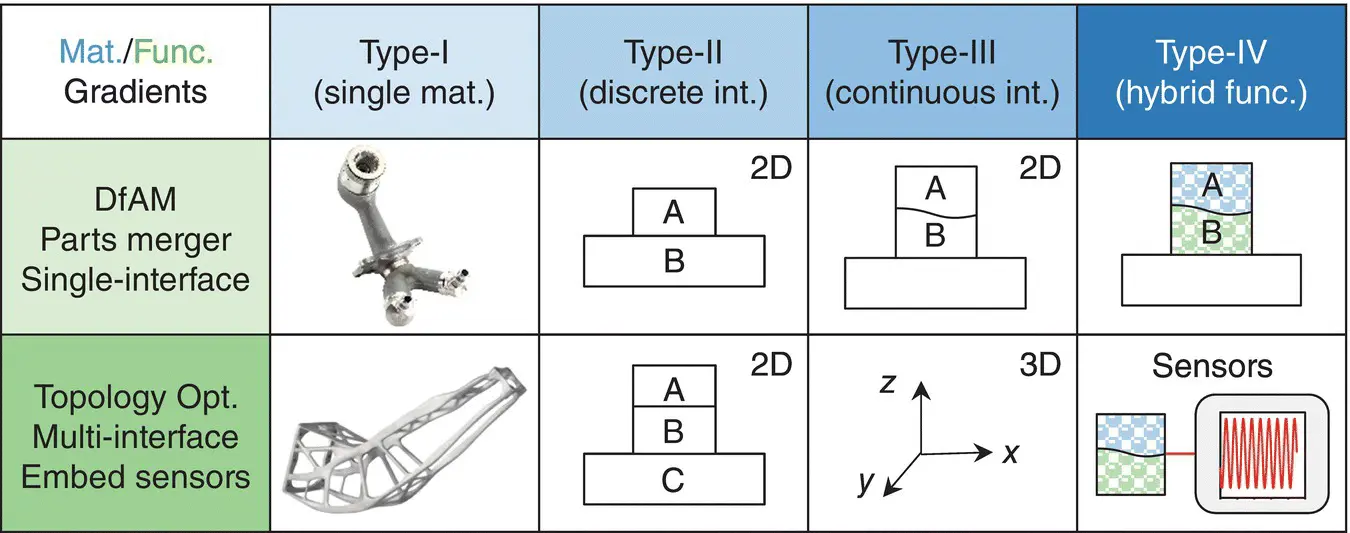

The digital nature of AM processes lends itself to the possibility of adding functionality to the components across the process chain, herein functionality relates to the form or geometry, as the geometry of the workpiece is built up from digital data, so does the functionality as relates to the material placement and material composition. Hofmann et al. [4] and Sobczak and Drenchev [5] explored the various classes of functionally graded metal components. It is useful to classify the functional gradients in AM components according to different kinds of material and geometric gradation. Figure 1.2shows a schematic of four types of material gradients in AM technologies. Type‐I is with a single material, and the functionality comes from the design and geometry of the structure. Type‐II deals with at least two materials used during the AM process, forming a discrete interface with an abrupt transition between the two materials. Type‐III involves at least two materials with a gradient interface between them. The material gradient can be introduced by process parameter change (microstructural control) or by in‐situ physical addition of multiple materials. Type‐IV refers to any hybrid functionality that is introduced by a combination of Types I−III or by the addition of sensors/other functional mechanisms. Functionality can also be achieved by integrating several AM processes into a hybrid process chain [6]. While the geometric gradients apply to most AM components (single/multi‐material), the material gradients are process dependent. Specifically, AM machine tools can change the material either at the voxel, layer, or part level. The capabilities of the process thus determine the kinds of functional gradients in AM components, which can be classified into geometric and material gradation.

Figure 1.1 Overview of physical and digital links of an AM process chain.

Figure 1.2 Schematic overview of functional AM components.

1.1.1 Industrial Application of Metal AM in the Energy Sector

Industrial applications of functional metal AM components can be found across various sectors including nuclear power, oil & gas, turbine components, wind & tidal energy, fuel cell components, and electromagnetic energy to name a few. Some such applications are discussed in this subsection. The GE Leap fuel nozzle was one of the first certified metal AM components to undergo high‐critical testing and deployment into production [7]. Siemens has been at the forefront of metal AM applications with replacement parts for nuclear plants, sealing rings for steam turbine blades and high‐efficiency gas turbine burners [8]. Oerlikon has showcased topology optimized turbine blades and drill bits for oil & gas applications with integrated sensors [9]. Biome renewables has designed and retrofitted an AM part to increase efficiency of existing wind and tidal turbine installations [10]. Aidro has manufactured high‐pressure hydraulic manifolds and heat exchangers for oil & gas applications [11]. The Oakridge National Lab (ORNL) has demonstrated a newly designed nuclear reactor core with multi‐material and integrated sensor functionality planned in the near future [12]. Optisys manufactures high‐performance antennas for critical electromagnetic energy sensor applications for satellites [13]. Thermal management applications—like heat exchangers, fuel cell components, and rocket nozzles—greatly benefit from the design freedom offered by metal AM [14]. The diversity of potential applications for metal AM in the energy sector is just starting to be explored. A better understanding of the potential can be gained by reviewing recent advances in functional metal AM components by classifying the functionality according to geometric and material gradients.

Читать дальше