Table 1.7 Utilization of heat in industries and their operating temperature ranges [17].

| S.no |

Industries |

Processes |

Range of temperatures [°C] |

| 1 |

Dairy Industry |

Sterilization Pressurization Concentrates Boiler feed water Drying |

100 to 120 100 to 120 60 to 80 60 to 90 120 to 180 |

| 2 |

Textile Industry |

Bleaching and Dyeing Degreasing Fixing Press |

60 to 90 100 to 130 160 to 180 80 to 100 |

| 3 |

Chemical Industry |

Preheating water Soaps Synthetic rubber |

60 to 80 200 to 260 150 to 200 |

| 4 |

Paper Industry |

Drying Bleaching |

60 to 80 130 to 150 |

| 5 |

Bricks and blocks |

Curing |

60 to 140 |

| 6 |

Meat |

Washing Sterilization Cooking |

60 to 90 60 to 90 90 to 100 |

| 7 |

Plastics |

Preparation and Blending Distillation and Separation Separation |

120 to 140 140 to 160 200 to 220 |

The commonly used solar thermal radiations in domestic and industrial operations are as follows [18]:

✓ Solar water heating

✓ Steam generation

✓ Solar drying

✓ Space cooling and refrigeration

✓ Solar distillation

✓ Cooking

✓ Power generation

1.8.1 Solar Water Heating Systems

One of the most needed domestic and industrial thermal applications is solar water heating technology and is more efficient compared to other types of solar equipment that are presently in use. In many of countries, SWH technologies are become more commercial and there is a greater growth utilization rate of about 30% from last few decades [13, 18].

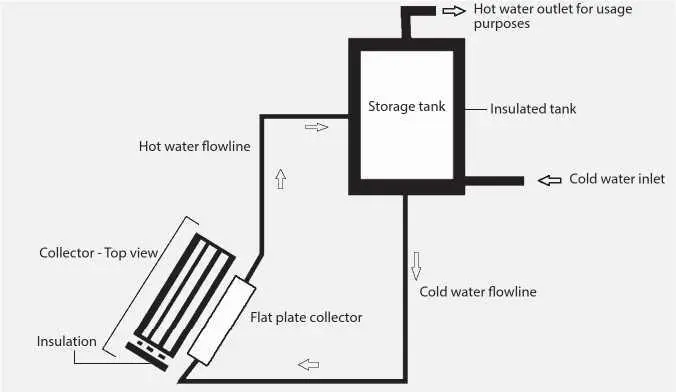

This type of systems constitutes the solar flat plate collectors and space for storage of water [13], which is insulated to avoid possibility of heat loss. Moreover, the heated liquid passed from the collector unit to storage tank occurs in two different methods as follows:

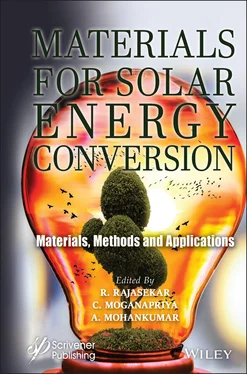

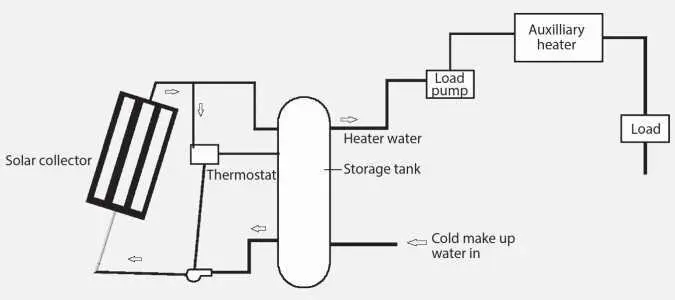

Figure 1.5 Natural circulation system [1].

✓ Natural mode of circulation

✓ Pumped mode of circulation

Natural Circulation

A small capacity unit is suited for home appliances in a natural mode of liquid transportation takes place as shown in Figure 1.5. The components used in this system are collectors and an insulated storage tank connecting two inlets: one is cold water that is traveled toward the collector from main pump line and another connected to tank from solar collector as heated fluid, where the tank is fixed above the height of the collector unit. The overall pipe line of the systems is to be covered with glass-wool material in order to minimize the heat loss [11]. Solar thermal radiation hits on the flat plate solar collectors from sunlight where it heats the fluid that passed inside the tube. Due to the density variation that occurs in the fluids between cold and heated, the heated water flows to the top of the storage tank through top header pipe line [13]. Cold fluid is entered into the tank from inlet of main pipe line when vacuum is generated.

Forced Circulation System

In an industrial process, a huge amount of heated fluid is needed for a certain operations. In such cases, the lower temperature fluid produced from thermo syphon method is not opted.

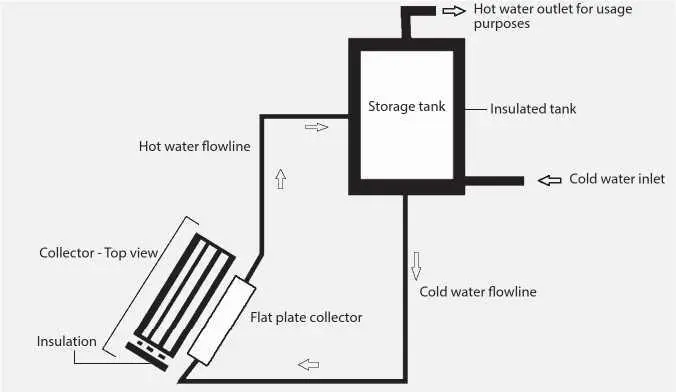

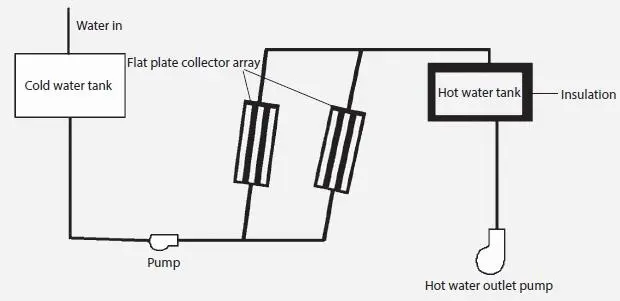

The number of solar collectors unit is connected in a series of array along with a external pumping system to circulate the fluid passage. Figure 1.6is the schematic diagram of forced circulation solar water heating system especially for industrial purposes like factories and hospitals.

Figure 1.6 SWH by forced circulation-Industrial purposes [19].

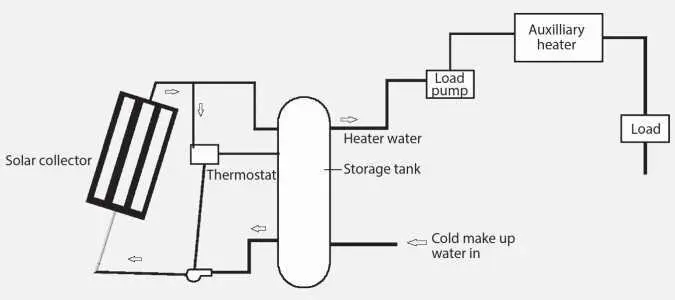

Figure 1.7 Forced circulation system—Domestic purposes.

Table 1.8 Types of solar energy applications and technologies involved in a systems [20].

| S.no |

Applications of solar energy |

Technologies used |

| 1 |

Solar water heating |

Natural Circulation system Forced Circulation system Collection cum storage water heater Built-in storage water heater Shallow Solar Pond water heater Direct Circulation Indirect Circulation water heating |

| 2 |

Refrigeration |

Adsorption Absorption |

| 3 |

Heating and Cooling systems |

Air systems Water systems Mechanical systems Heat pump |

| 4 |

Solar Distillation |

Solar stills Vapor compression systems Multiple effect boiling |

| 5 |

Solar power generation |

Parabolic tower Parabolic dish Solar furnaces |

In this SWH operation, it contains the solar collectors, external pump to circulate the fluid, thermostat, and non-return valve. The controller is used to regulate the temperature during process. If the predetermined value of temperature exceeds, then valve becomes open to mix up heat water with supplying water system, and finally, it reaches the desired temperature as per required needs. Auxiliary heater provision is also made in this system [1]. There are two modes of technology developed in this system that are flows through a passage and recirculating water heaters [20]. The former technology is applied mostly in industrial operations and latter is same as used in the domestic heating purposes [20] and shown in Figure 1.7. The different types of solar energy applications and technologies involved in systems are explained in Table 1.8.

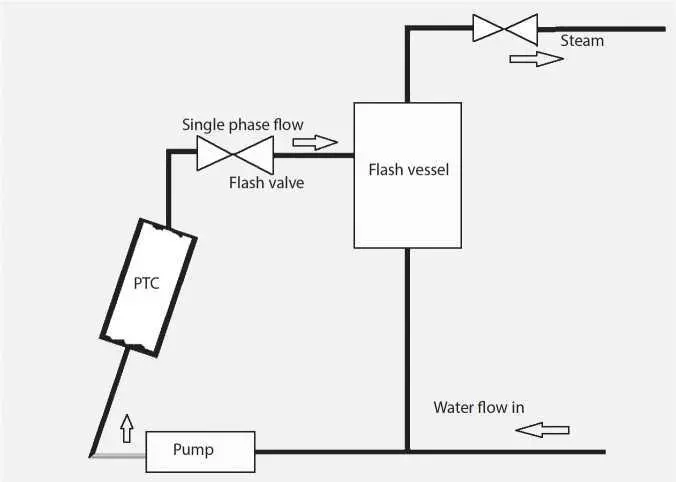

In sterilization operations, the lower temperature vapor is widely applied. Most commonly, the higher temperature is obtained in parabolic trough collectors, which is more effective method also among other sources of solar collectors. There are three working theories established [21] in a PTCs to produce steam as follows: steam flash, direct, and unfired boiler.

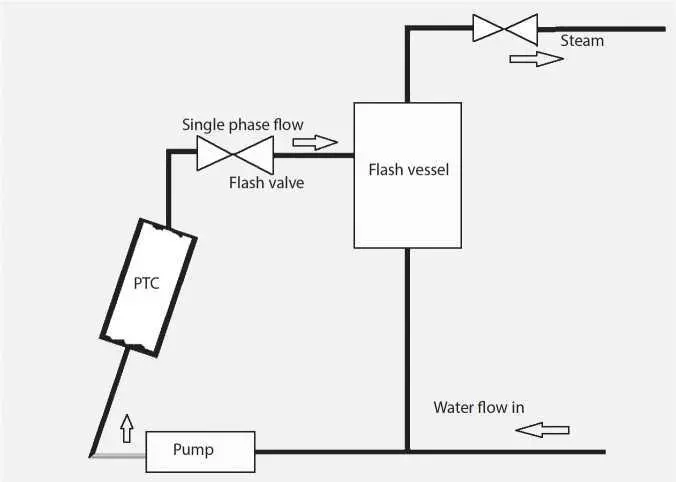

Figure 1.8 Flash type [1].

Figure 1.9 Direct method [1].

In the first method, pressurized heated fluid is rushed in a separate vessel to obtain steam. The second method is an in situ; in this type, steam production is reached through the way of two phase flow type, and in the latter method, heat exchanger device helps to produce steam. In all these above working procedures, the heated water flows into the collectors.

Figure 1.8shows the steam flash type where fluid is increased in the range of pressure to eliminate boiling, and then, it enters into collector and further moved into flash vessel. Fluid range is steadily maintained throughout the makeup water inlet.

Figure 1.9denotes the direct type, and the change in this method compared with the former method is flash valve detached from the system. The feed water directly flows to the receiver end as heated water. Both these methods are quite lesser cost to installation [22].

Читать дальше