Polymer Composites for Electrical Engineering

Здесь есть возможность читать онлайн «Polymer Composites for Electrical Engineering» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Polymer Composites for Electrical Engineering

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 100

- 1

- 2

- 3

- 4

- 5

Polymer Composites for Electrical Engineering: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Polymer Composites for Electrical Engineering»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Polymer Composites for Electrical Engineering

Polymer Composites for Electrical Engineering

Polymer Composites for Electrical Engineering — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Polymer Composites for Electrical Engineering», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

Three‐dimensional metal foams (copper foam, nickel foam, and aluminum foam) with continuous skeleton structure exhibit excellent mechanical properties, ultra‐low relative density, high porosity, and high thermal conductivity, but they are mainly used for the preparation of PW‐based phase change composites. In addition, it is worth noting that the pore size of commercial metal foams is generally large, which is not conducive to the improvement of shape stability of phase change composites. Meanwhile, copper nanowire aerogel[86] and silver/polyvinylpyrrolidone (PVP) nanowire aerogel[87] with tunable structures have been developed to yield phase change composites with enhanced thermal and electrical conductivities, exhibiting great potentials in metal‐based polymeric phase change composites for thermal energy conversion and storage.

2.3.2 Carbon Materials

Owing to the low density, excellent thermal/chemical stability, and high thermal conductivity, carbon materials can be considered as one of the most promising candidates for production of thermally conductive phase change composites. CNT,[88–90] CF,[91] EG,[54] and GNP[89, 92, 93] have been employed to develop PEG‐based phase change composites with enhanced thermal conductivity. Additionally, carbon materials [94] can be added into leakage‐proof composites containing supporting polymers to improve the thermal conductivity. Noteworthy, it is essential to conduct thermal annealing treatment at high temperature to repair the defects corresponding to phonon scattering when GO is employed as precursor to yield graphitized graphene with high intrinsic thermal conductivity for thermally conductive phase change composites.

In addition to direct introduction of carbon‐based fillers into phase change matrices, 3D carbon‐based structural materials have been widely used to prepare phase change composites in recent years. Three‐dimensional thermally conductive networks have been successfully constructed in polymeric PCMs by incorporating biological porous carbon,[16] nanofibrillated cellulose/CNT aerogel,[67] cellulose/graphene aerogel,[68] microcrystalline cellulose/GNP aerogel,[95] GO/GNP hybrid aerogel,[55] and cellulose nanofiber/GNP hybrid‐coated melamine foam[96]. Owing to that the nanostructured materials are physically overlapped through π–π interaction in common carbon‐based aerogel/foam prepared by self‐assembly strategy, there is pronounced thermal contact resistance at the joints. Covalent‐bond diamond and graphene foams prepared by chemical vapor deposition (CVD) are able to provide continuous phonon transmission pathway. Unfortunately, these hydrophobic foams are preferential for nonpolar PCMs like PW. Hydrophilic modification such as plasma treatment is considered as an effective solution to enrich the variety of phase change composites.

2.3.3 Ceramics

Compared with electrically conductive metal and carbon materials, ceramics represented by BN gain unprecedented popularity in the fabrication of thermally conductive yet electrically insulating phase change composites, expanding their application scenarios. Thermally conductive PEG/silicon nitride (Si 3N 4) nanowire phase change composites have been developed via a facile solution blending.[97] AlN[98] and Al 2O 3[99] have been used as functional fillers to improve thermal conductivity of shape‐stabilized PEG/SiO 2phase change composites. Similarly, SiC nanowires have been incorporated into leakage‐proof PEG/EVM composites to improve the thermal conductivity.[100] PEG and BN have compounded by melt blending,[101] solution blending,[17] and interfacial polyelectrolyte complex spinning[102] to fabricate polymeric phase change composites with high thermal conductivity.

In order to improve the utilization efficiency of functional fillers and construct thermally conductive pathways, ceramic‐based porous scaffolds have been proposed for polymeric phase change composites. Unfortunately, it is more difficult to exfoliate and functionalize BN than graphite owing to the higher electronegativity of N atoms originating from the partially ionic B‐N bonds, and thus the formation of 3D‐BN structural materials without the assistance of auxiliary materials remains a challenging problem. It has been proved that chitosan,[103] cellulose,[69] and GO [66, 104, 105] can be used as supporting materials or binders to help BN build 3D conductive network for polymeric phase change composites. For example, GO/BN porous scaffolds with isotropic and aligned structures have been designed through a facile yet powerful freeze‐casting to fabricate thermally conductive PEG‐based phase change composites,[66, 104, 105] and the final composites with a phase change enthalpy of 143.6 J g −1exhibit enhanced thermal conductivity as high as 3.18 W m −1K −1at BN loading of c. 28.7 wt%.

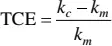

Furthermore, hybrid fillers with different geometries, such as silver‐graphene[57] and GNP‐BN[106], are capable of forming synergistic network structure to improve the thermal conductivity of PEG‐based phase change composites. Metals, carbon materials, ceramics, and their hybrids can be employed as enhanced component to produce electrically conductive or insulating polymeric phase change composites with high thermal conductivity through facile solution blending, melt blending, and vacuum impregnation methods. More details are summarized in Table 2.4, in which thermal conductivity enhancement (TCE) is defined by Eq. (2.1). Constructing 3D conductive network in phase change composites seems to be an efficient route to achieve a trade‐off among shape stability, thermal conductivity, and energy storage density, attracting ever‐growing interest.

(2.1)

where k cand k mrepresent the thermal conductivities of composites and matrix or matrix with supporting materials, respectively.

2.4 Energy Conversion and Storage Based on Polymeric Phase Change Composites

In recent years, energy conversion, storage, and utilization based on PCMs have become the research frontiers, especially for solar energy, industrial waste heat, and surplus heat. As‐prepared phase change composites with improved comprehensive performance can achieve efficient energy conversion and storage via electro‐to‐heat ( Figure 2.7a),[95] photo‐to‐heat ( Figure 2.7b),[88, 95, 109] magnetism‐to‐heat ( Figure 2.7c),[107] heat‐to‐electricity ( Figure 2.7d),[108] and photo‐to‐heat‐to‐electricity ( Figure 2.7e)[105] routes, providing a strong support for the popularization of advanced energy‐related devices and systems associated with functional PCMs. Also, both solid–liquid and solid–solid polymeric phase change composites can realize these energy conversion routes.

2.4.1 Electro‐to‐Heat Conversion

Electric thermal storage technique based on PCMs is expected to improve the utilization efficiency of power generation equipment and exhibits broad prospects in the field of off‐peak electricity. Unfortunately, the electrical conductivity of PCMs is inherently low, which makes it impossible to directly employ them for electro‐to‐heat conversion. It is usually necessary to incorporate functional fillers to improve the electrical conductivity of phase change composites, and carbon materials, including biomass carbon,[110] carbon nanofiber (CNF),[111] CNT,[109] and graphene[112], are preferentially considered. Of critical importance is the electro‐to‐heat conversion and storage efficiency ( η e), which can be defined by the ratio of stored heat energy to applied electric energy during phase change process and determined by the electro‐thermal calculation Eq. (2.2).

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Polymer Composites for Electrical Engineering»

Представляем Вашему вниманию похожие книги на «Polymer Composites for Electrical Engineering» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Polymer Composites for Electrical Engineering» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.