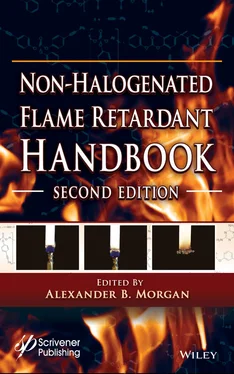

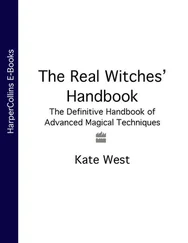

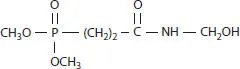

Similarly to PU foams, phosphorus based FR for textile finishing don’t need to be di- or multifunctional. For many years the product of the addition of dimethyl phosphite to acrylamide followed by methylolation ( Formula 2.15) was marketed for cotton and cotton-based blends [258]. This product is fixed on the cellulose using an amino resin and an acid curing catalyst. A recent academic study [259] shows that use of titanium dioxide as a co-catalyst for cotton textile treatment improves the flame retardant efficiency especially after laundering. It has a mild formaldehyde odor because it contains some components with less well bound formaldehyde [260]. This product is not used in the USA and has limited use in Europe because of potential formaldehyde exposure. There are methods of decreasing formaldehyde release [261] and it is believed that they are used commercially. A recent patent application [262] shows use of this product on lyocell fibers where it is introduced in the spinning solution.

(2.15)

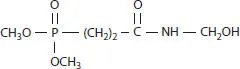

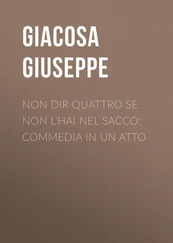

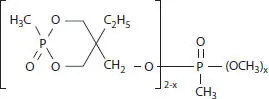

Termosol finishes with phosphorus-based flame retardants have been used for many years in PET textiles [263] and probably in polyamides. The major product used in the thermosol treatment of polyesters is a liquid cyclic phosphonate ( Formula 2.16). It is a mixture of diphosphonate and triphosphonate with the ratio mostly shifted towards diphosphonate x=1. Usually, a small concentration of phosphorus 0.3-0.5 wt. %, in PET is needed to pass the textile flammability test NFPA 701 and 0.7 wt.% is needed to pass the vertical FAR 25.853 test for use in aviation airbags [264]. Even being highly soluble in water, after the phosphonate is trapped under the fibers surface it is resistant to laundering and doesn’t leak out. Because this phosphonate has a high phosphorus content it is also attractive for use in rigid or flexible PU foams. However, it has high viscosity and needs to be diluted with an aromatic phosphate [265] or bisphosphate [266]. A version of the spirophosphonate where the ratio is mostly shifted to triphosphonate ( Formula 2.16, x is mostly 0) has shown promise as an additive in polyamide fibers via a melt process [267].

(2.16)

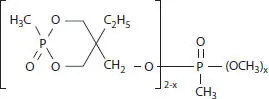

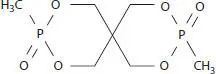

About a decade ago pentaerythritol spirobis(methylphosphonate) ( Formula 2.17) was introduced for use in polyamides, including melt-spun fibers [268] and for use in combinations with intumescent flame retardants in polyethylene [269]. When combined with a free-radical generator, it is effective for flame-retarding polyethylene foam [270] and thin polyethylene films [271]. Another application of spirobis(methylphosphonate) seems to be in polyurethane based textile backcoatings [272]. In a recent academic publication [273] it was found that spirobis(methylphosphonate) has a higher flame retardant efficiency in molded PET compared to a bisphosphate, bisphosphinate and bis-n,n-naphthtylimide of similar structure. This high efficiency was attributed to the phosphorus gas phase action.

(2.17)

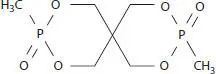

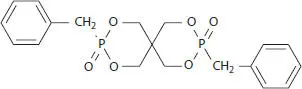

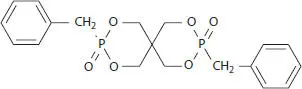

Similarly pentaerythritol spirobis(benzylphosphonate) ( Formula 2.18) has been developed in Japan and introduced as a flame retardant for thermoplastic polyesters and styrenics [274]. However, based on later patents the main applications of this product seem to be in polylactic acid [275] and its blends [276] and in bio-based polycarbonate [277]. It doesn’t affect the transparency and the clarity of the polycarbonate. Other potential applications are poly(methyl methacrylate) and its blends [278], backcoating for polyester textiles [279] and polyurethane based artificial leather [280].

(2.18)

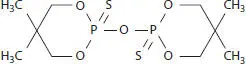

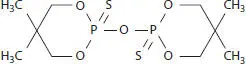

1,3,2-dioxaphosphorian-2,2-oxy-bis-(5,5-dimethyl-2-sulphide) ( Formula 2.19) is a solid flame retardant additive developed and commercialized in Europe for use in viscose rayon [281]. Despite the anhydride structure, it is remarkably stable, surviving addition to the highly alkaline viscose, the acidic coagulating bath, and also resisting multiple laundering of the rayon fabric. The unusual stability may be attributed to the sulfur atoms, which enhance hydrophobicity, and to the sterically hindering neopentyl groups that retard hydrolysis. The process of producing flame-retardant viscose fibers has been improved in recent years [282] because of increasing use of rayon as a fire barrier in mattresses.

(2.19)

Other commercial aliphatic phosphates e.g., tributyl phosphate, triethoxybutyl phosphate and tri-2-ethylhexyl phosphate can be used as a flame retardants or part of a flame-retardant mixture, but their major use is in other areas. Therefore, they are out of the scope of this chapter.

2.7 Aromatic Phosphates and Phosphonates

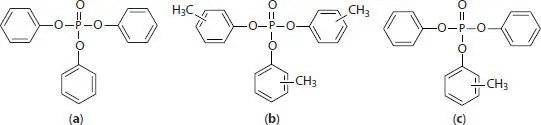

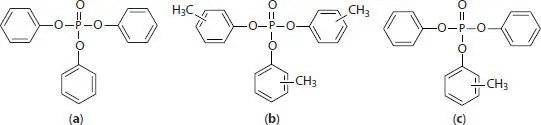

Triphenyl phosphate (TPP, Formula 2.20(a)), a white low melting (48°C) solid, and tricresyl phosphate (TCP, Formula 2.20(b)), a liquid, were introduced into commercial use early in the twentieth century, initially for cellulose nitrate and later for cellulose acetate. TPP is usually produced in the form of flakes or shipped in heated vessels as a liquid. TPP has also been used as a flame-retardant additive for engineering thermoplastics such as polyphenylene ether–high impact polystyrene (PPE/HIPS) [283] and polycarbonate-ABS (PC/ABS)[284] blends. The largest use of TCP has been as a plasticizer for PVC [285]. In recent years some adverse aquatic toxicity data and later discovery of endocrine disruption effects of TPP led to a significant decrease in its use. Manufacturers of aromatic phosphates are now in the process of eliminating it from other products where it is present as a blend component or as an impurity. Originally tricresyl phosphate was made from petroleum-derived or coal-tar-derived cresols. Discovery of the toxicity of ortho-cresyl phosphates led manufacturers to switch to synthetic cresols having very little o -cresol, but this significantly increased the cost of TCP and almost eliminated it from the market. Another product from the same family, cresyl diphenyl phosphate (CDP, Formula 2.20(c)), took the market share of TCP, but mostly in Europe.

(2.20)

Typical applications of TCP and CDP are in PVC tarpaulins, mine conveyer belts, air ducts, cable insulation, and vinyl films. These phosphates are usually used in blends with phthalates. The proportion of the more expensive phosphate is usually chosen such as to permit the product to reliably pass the flammability specifications. Other uses of CDP are in various rubbers, polyisocyanurate foams [286], semi-rigid PU foams in combination with expandable graphite [287], in phenolic and epoxy laminates [288] and as a plasticizer in epoxy-based coatings [289].

In the late 60s, the use of more economical synthetic isopropyl- and tert -butylphenols as alternatives to cresols was developed [290, 291]. Commercial triaryl phosphates are based on partially isopropylated or tert -butylated phenols. Made from the product of isopropylation of phenol by propylene, isopropylphenyl phenyl phosphate ( Formula 2.21(a)) is a mixture of mainly ortho - and para -isomers and contains a distribution of different levels of alkylation [292, 293]. The plasticizer performance of isopropylphenyl phenyl phosphate is close to that of TCP. Mixed tert -butylphenyl phenyl phosphate ( Formula 2.21(b)), is a slightly less efficient plasticizer for PVC by itself but it is quite effective in blends with phthalate plasticizers. Both commercial isopropylated and tert -butylated phosphates contain a significant amount of TPP. tert -Butylphenyl phenyl phosphate is the least volatile and the most oxidatively stable in the family of alkylphenyl phosphates [294].

Читать дальше