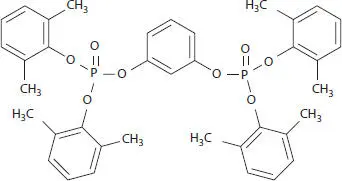

(2.26)

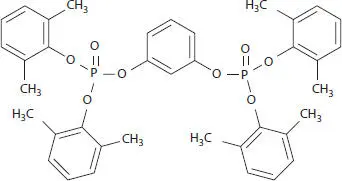

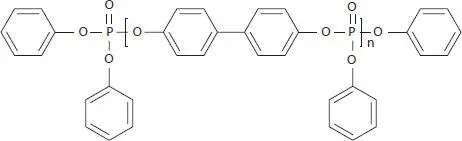

4,4’-Biphenyl bis(diphenyl phosphate) ( Formula 2.27) is a specialty bisphosphate for high temperature molding of glass-filled PC and PC/ABS [326]. It has a melting range of 65-85°C [327] and a phosphorus content of about 9.5 %. It gives a V-0 rating in PC at 3.5wt. % loading and 0.3 wt. % PTFE and at 10 wt. % loading it gives a V-0 rating in PC/ABS and a comparative tracking index (CTI) of 600 V [328]. When used without PTFE it preserves the transparency of polycarbonate [329]. As measured by thermogravimetry, 4,4’-biphenyl bis(diphenyl phosphate) shows a 5 wt. % loss at about 405°C which is significantly higher than other bisphosphates. Because of its low melting point this bisphosphate requires a significant cooling system in order to avoid bridging in the extruder feeding ports. A recently developed variation of the same bisphosphate, but with a significantly higher content of oligomeric fraction (n>1, 30-40%) is a viscous liquid [330].

(2.27)

Academic studies [331, 332] on the mechanism of the flame-retardant action of aromatic phosphates in a PC based blend revealed that BDP shows mostly condensed phase action, RDP shows a mixed condensed phase and gas phase, whereas TPP is mostly gas-phase-active. This was attributed to the temperature of decomposition of PC and phosphates, e.g., TPP evaporates at a relatively low temperature and doesn’t have a chance to react with PC, whereas bisphosphates react with PC [333, 334]. RDP or BDP tend to cause PC to produce more char, decreasing the fuel supply to the flame and decreasing the flame temperature. TPP, which has gas phase activity, becomes more effective in the gas phase with a decrease in the flame temperature. HDP shows significant gas phase efficiency and when mixed with a mostly condensed phase active BDP exhibits a synergistic effect [335]. Another study showed [336] that the hindered structure of RXP slows down the reaction with PC and therefore it shows less condensed phase action compared to RDP. Interestingly talc improves the flame retardant efficiency of bisphosphates because of the better protective properties of the char [337] and on the other hand glass fiber reinforcement deteriorates the flame retardant efficiency because it increases the combustion surface (candlewick effect) [338].

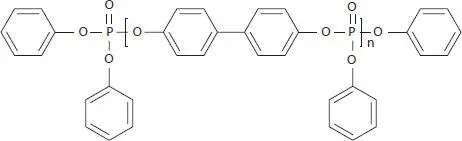

Another large application of aromatic bisphosphates and oligomers is in polyphenylene ether (PPE) based blends. Polyphenylene ether cannot be processed alone because of its very high melting temperature, but it is readily compatible with many polymers and can be processed as a blend. Depending on the molecular weight and chain ends PPE can be blended with HIPS, polyamides, styrenic elastomers and even epoxy. Apart from improving the physical properties of the host polymer, PPE is an excellent charring polymer due to its specific thermal decomposition mechanism ( Formula 2.28). PPE undergoes Fries isomerization [339] and forms a phenolic type of resin with numerous OH groups which are reactive with phosphorus FRs.

(2.28)

Commercial PPE/HIPS blends, also known as modified PPE, contain from 35 to 65 wt. % PPE. Similarly to PC/ABS, the first FR used in PPE/HIPS was TPP, which was later replaced with RDP and BDP [340]. Typically, between 9 and 15 wt. % of a phosphate ester is needed to achieve V-0 rating; the lower the PPE content in the blend, the higher the phosphate loading required. PTFE is required to prevent dripping. A copolymer of polydimethyl- and polydiphenyl siloxane can prevent dripping and is at the same time synergistic with RDP [341]. Addition of polysiloxane also helps to decrease smoke formation allowing the achievement of HL3 rating in the European mass transit test EN 45545 in PPE/HIPS based glass fiber composites [342]. Apart from flame retardancy, phosphate esters also play an important role in plasticization and resin flow improvement. Therefore, some phosphate esters can be added to PPE/HIPS even if flame retardancy is not needed. Because PPE is not sensitive to hydrolysis, any bisphosphate can be used in high humidity applications, as for example water pipes [343].

Apart from HIPS, PPE is also compatible with styrene based thermoplastic elastomers, such as styrene-ethylene-butylene-styrene (SEBS) block copolymer. A copolymer of SEBS and maleic anhydride is used as a compatibilizer [344]. These blends are mostly used in electric wire jackets and often polyolefins and HIPS are also included in the blends. As the patent literature indicates, aromatic bisphosphates RDP [345] and BDP [346] were originally used as flame retardants in PPE/SEBS blends. Bisphosphates are very compatible and soluble in PPE, but not in TPEs and polyolefins and therefore the total loading of bisphosphates is limited because of potential exudation. To overcome this problem in blends containing less than 50% PPE, solid flame retardants are added along with bisphosphates. The patent literature shows combinations of aromatic phosphates with magnesium hydroxide [347], melamine phosphates [348], ammonium polyphosphate [349] or DEPAL [350].

Mechanistic studies of the flame-retardant action of bisphosphates and TPP in PPE based blends showed that phosphates catalyze the Fries rearrangement [351] ( Formula 2.28) and promote charring and improve the morphology of the char by making it intumescent-like [352]. The PPE charring capability is higher than PC, therefore PPE improves the fire retardant performance of RDP in PC/PBT blends [353]. One comprehensive study [354] looked at a large number of substituted aromatic phosphates and bisphosphates and compared them with red phosphorus and aliphatic phosphates. This study concluded that aliphatic phosphates are the least efficient because they decompose at temperatures much lower than the decomposition temperature of PPE. The efficiency of all aromatic phosphates and bisphosphates were similar in the range of experimental error and directly proportional to the phosphorus content. The efficiency of red phosphorus was similar to that of aromatic phosphates at the same phosphorus concentration. However, the strongest factor that controls the flammability of PPE/HIPS blends was the PPE content [355].

Another use of aromatic bisphosphates is in TPU. One of the common commercial halogen-free TPU formulations is based on about 25 wt. % melamine cyanurate and 5 wt. % RDP [356]. This TPU still drips, but the droplets do not ignite cotton and therefore it is rated V-0. Addition of some free isocyanate during processing creates additional cross-links and prevents dripping [357]. Many formulations based on RDP and ATH passing the VW-1 rating in the UL-1581 test for wire and cables applications were developed [358] and some were probably commercialized. Interestingly, the addition of only 2.5 wt. % novolac type epoxy resin provides robustness in passing the test [359] probably by cross-linking and decreasing the resin flow and dripping.

Various aromatic bisphosphates, more specifically RDP [360] can be incorporated by the exhaust method in PET textiles in the presence of polycaprolactone as a dispersing agent and polyethylene diamine as an auxiliary FR helping to retain RDP in the fiber. An add-on level > 10 wt. % was achieved and the textile passed the stringent DIN 54336 test with immediate extinguishment. A similar result was achieved by dispersing RDP, BDP or RXP in water using a non-ionic surfactant with a small addition of a cationic surfactant and then immersing the PET fibers at 130°C in an autoclave [361]. Emulsified RDP can also be applied as a backcoating to a nylon/cotton fabric blend [362]. In terms of combustion performance films are often close to textiles. About 8 wt. % RDP was used to pass the FMVSS 302 test in polyester films based on ethylene and 1,4-cyclohexanedimethane terephthalate [363] or 3 wt. % in a 45 degree flame spread test in poly(trimethylene terephthalate) film [364].

Читать дальше