(1.3)

(1.4)

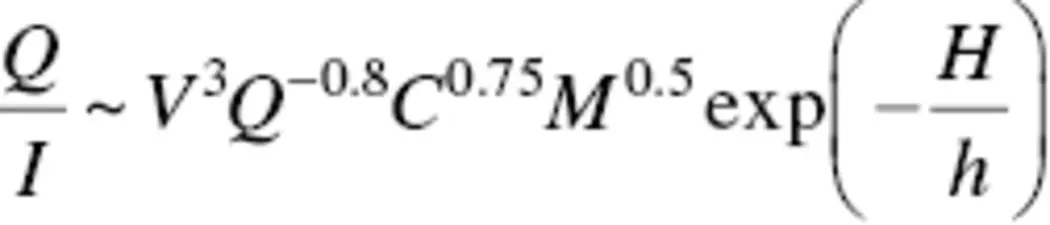

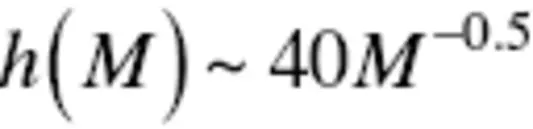

(1.5)

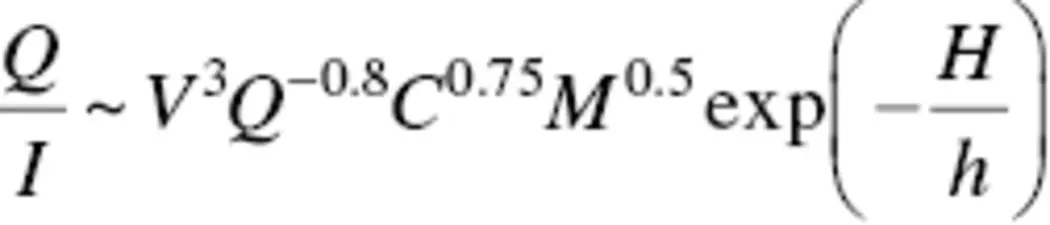

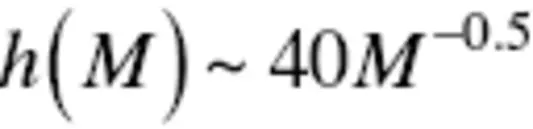

where V is applied voltage, Q is flow rate, C polymer concentration, M molecular weight, and H tip to collector distance. Using PEO/water/ethanol mixtures, the solvent properties also slightly affect the current and volumetric charge density. From this work, it is evident that the fiber size is affected by applied electric field strength (applied voltage and time to collector distance), flow rate, and polymer solution (Thompson et al. 2007). Thus, these predictions for fiber size rely on several model parameters that cannot be easily related to measurable variables.

In another work by Rutledge and coworkers, they experimentally determined that the total current in electrospinning, given by

(1.6)

varies electric field ( E ), volumetric flow rate ( Q ), and solution conductivity ( K ). In electrospray, the measured current scales linearly with Q . The authors attributed the observed Q 0.5dependence on combined jet and spray arising from secondary jetting. Secondary jetting was considered a mechanism for dynamic removal of charge from the surface of the jet which affects final fiber diameter and reducing jet stretching due to surface charge repulsion. The secondary jetting can be minimized by reducing the volumetric flow rate or solution conductivity (Bhattacharjee et al. 2010).

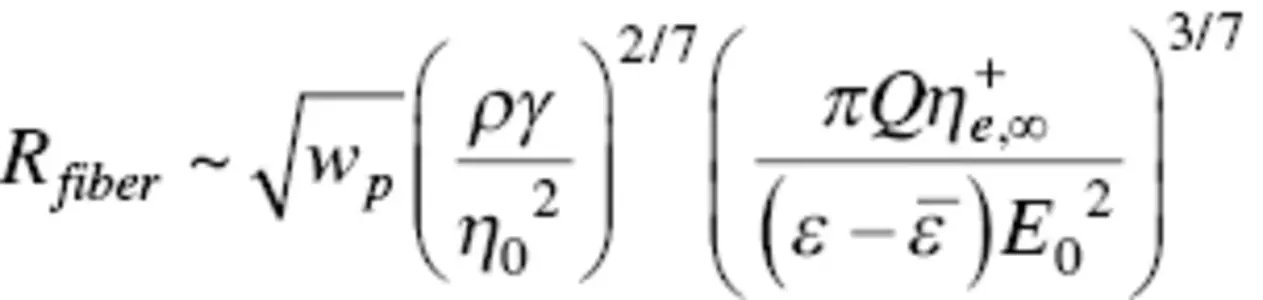

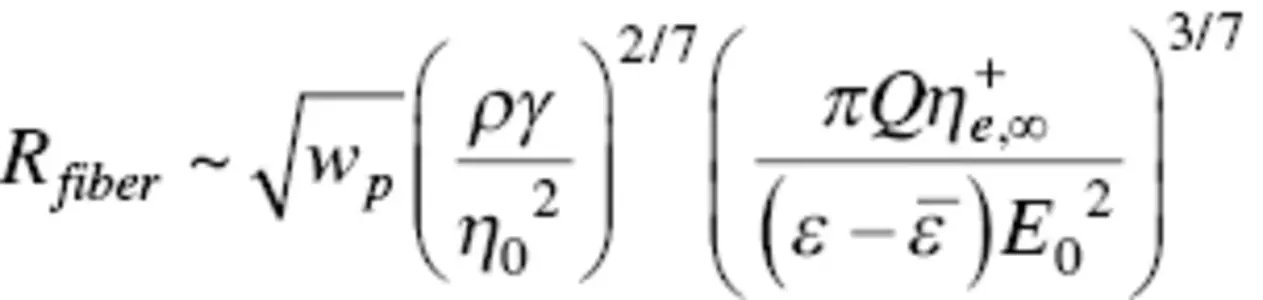

Alternative scaling analyses based on the spinning solution properties and electrospinning operating conditions alone have been developed. Based on electrohydrodynamic theory, the Taylor–Melcher slender body theory relates jet kinematics to measurable fluid properties and process variables. Helgeson et al. validated the electrohydrodynamic model with measurements of the jet radius and velocity via in situ high‐speed photography and velocimetry in the straight portion of viscoelastic electrospinning jet and PEO/NaCl as a model system. Dimensional analysis of the validated model involves two important quantities the electroviscous number characterizing the electromechanical stress relative to shear stress and the Ohnesorge number (Oh). The relationship for the final fiber diameter was determined to be

(1.7)

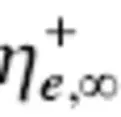

where w pis the mass fraction of polymer in solution, ρ is solution density, γ is surface tension, η 0is the zero shear viscosity, Q is the volumetric flow rate,  is the extensional viscosity, ε is the dielectric constant of the fluid,

is the extensional viscosity, ε is the dielectric constant of the fluid,  is the dielectric constant of the surrounding medium (typically atmosphere), and E 0is the strength of the applied electric field. This analysis explicitly contains the extensional viscosity of the fluid known to control fiber formation. The extensional viscosity can be estimated as 3 η 0for a Newtonian fluid. This approach assumes the final fiber is directly proportional to jet radius in the straight portion of the jet and the actual relationship may be system‐dependent, i.e. influenced by solution conductivity and mechanics of the bending instability (Helgeson et al. 2008). The predictions agree with experimental observations over a broad range of polymer concentrations and voltages. Upon addition of a significant amount of NaCl, the trends are consistent, but the scaling factor changes and may be attributed to the differences in the bending instability.

is the dielectric constant of the surrounding medium (typically atmosphere), and E 0is the strength of the applied electric field. This analysis explicitly contains the extensional viscosity of the fluid known to control fiber formation. The extensional viscosity can be estimated as 3 η 0for a Newtonian fluid. This approach assumes the final fiber is directly proportional to jet radius in the straight portion of the jet and the actual relationship may be system‐dependent, i.e. influenced by solution conductivity and mechanics of the bending instability (Helgeson et al. 2008). The predictions agree with experimental observations over a broad range of polymer concentrations and voltages. Upon addition of a significant amount of NaCl, the trends are consistent, but the scaling factor changes and may be attributed to the differences in the bending instability.

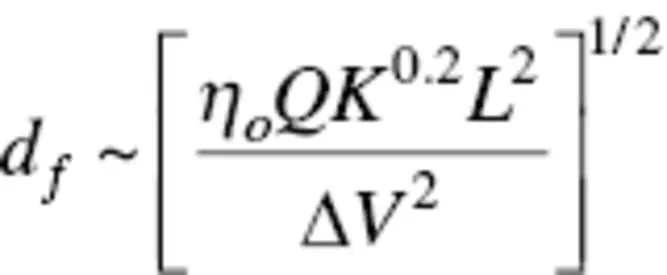

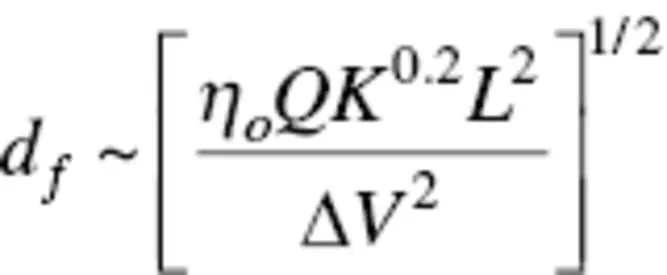

Recently, using a force balance on a bent jet considering electric field and surface charge for a Newtonian fluid, Gadkari predicted the final fiber diameter ( d f) scales as

(1.8)

where η ois viscosity, K is conductivity, Q is flow rate, L is tip to collector distance, and V is applied voltage. When compared to experimental results, the scaling prediction qualitatively matches the observed trend for viscosity, flow rate, and applied voltage. The model overpredicts the dependence on volumetric flow rate (0.5 dependence predicted, whereas a 0.3 dependence has been observed experimentally). Experimental values for the scaling relationships for Δ V , L , and K were not available (Gadkari 2014).

1.2.2 Experimental Results

Collectively, theoretical considerations indicate that fiber size is affected by applied electric field strength (applied voltage and time to collector distance), volumetric flow rate, and polymer solution (viscosity and conductivity). However, experimental results have been system‐dependent. For example, experiments increasing the voltage has been observed to decrease fiber diameter for many systems such as polyacrylonitrile/DMF and aqueous polyvinyl alcohol due to greater stretching and a stronger electric field. (Andrady 2008). For polyacrylonitrile in DMF, fiber diameter was reduced from ~95 to 50 nm by increasing the voltage from 5 to 25 kV. Conversely, fiber size has increased with increasing voltage. For example, the polystyrene (PS) fibers increased in diameter from 0.31 to 1.72 μm when the applied voltage increased from 5 to 25 kV. The discrepancy in experimental observations indicates that the effect of voltage on fiber size needs to be considered with other process parameters, especially the feed rate and tip‐to‐collector distance. Notably, at higher applied voltages, there is a greater tendency for bead formation. The bead density increased with increasing voltage and the shape of the beads transitioned from spindle‐like to spherical‐like indicating instability of the jet (Ramakrishna 2005).

Tip‐to‐collector distance influences the time of travel, amount of drying, and electric field strength (depending on the applied voltage) and thus the resulting fiber diameter and morphology. Practically, the distance must be large enough to prevent corona discharge. Generally, increasing the tip‐to‐collector distance with other parameters kept constant reduces fiber diameter. For example, electrospinning polystyrene in chloroform, the fiber diameter decreased from 1 to 0.66 μm by increasing the distance from 5 to 25 cm due to increased time of travel and stretching. Conversely, increasing the distance has also been observed to increase fiber diameter due to the reduced electric field strength. Decreasing the tip‐to‐collector distance and resulting time of travel and amount of drying can lead to deposition of “wet” fibers that fuse on the collector. While higher electric field strengths can be achieved at shorter distances, it can often result in the formation of beads or an unstable Taylor cone if the distance is not sufficient for development of the whipping instability (Andrady 2008; Ramakrishna 2005).

Читать дальше

is the extensional viscosity, ε is the dielectric constant of the fluid,

is the extensional viscosity, ε is the dielectric constant of the fluid,  is the dielectric constant of the surrounding medium (typically atmosphere), and E 0is the strength of the applied electric field. This analysis explicitly contains the extensional viscosity of the fluid known to control fiber formation. The extensional viscosity can be estimated as 3 η 0for a Newtonian fluid. This approach assumes the final fiber is directly proportional to jet radius in the straight portion of the jet and the actual relationship may be system‐dependent, i.e. influenced by solution conductivity and mechanics of the bending instability (Helgeson et al. 2008). The predictions agree with experimental observations over a broad range of polymer concentrations and voltages. Upon addition of a significant amount of NaCl, the trends are consistent, but the scaling factor changes and may be attributed to the differences in the bending instability.

is the dielectric constant of the surrounding medium (typically atmosphere), and E 0is the strength of the applied electric field. This analysis explicitly contains the extensional viscosity of the fluid known to control fiber formation. The extensional viscosity can be estimated as 3 η 0for a Newtonian fluid. This approach assumes the final fiber is directly proportional to jet radius in the straight portion of the jet and the actual relationship may be system‐dependent, i.e. influenced by solution conductivity and mechanics of the bending instability (Helgeson et al. 2008). The predictions agree with experimental observations over a broad range of polymer concentrations and voltages. Upon addition of a significant amount of NaCl, the trends are consistent, but the scaling factor changes and may be attributed to the differences in the bending instability.