The numerical created model for resulting documentation and assumptions.

The accompanying assumptions are considered to build up this model.

The request cost for the thing is Inventory organized.

Shortages are allowed.

Instantaneous request and stable Replenishment.

Stock decayed during the arranging skyline are repairable.

Holding cost, Set-up cost, Shortage cost and unit cost stay consistent over the long run.

The dispersion of an opportunity to fall apart follows a four Parameters.

Replenishment is quick.

This section begins with a listing of the Notations used.

S = Highest Stock stage.

f (d) = Probability density characteristic of Demand.

D = Deterioration.

Q = Optimum production order amount.

CS = Shortage price. CH = Holding Price per unit per unit of duration held in Stock. Q* = Back ordering is permitted. I = units per year C = Unit price for producing or purchasing every unit, TEC 1(Q) = Optimum Inventory achieve local minimum. TEC 1(I)= Expected price. TEC (Q*) = Conditional for Ordering.

1.2.3.3 Model Formulation

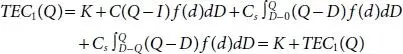

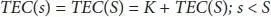

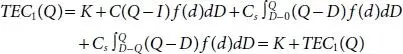

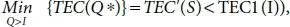

This model is the same as fixed setup cost for buying any units to renew Stock at start of period, say K, is related buy or making things in a given timeframe or cost of assembling. Leave I alone the Inventory stage toward the start of the level infers that a request size (Q-I) thing can be set to pass on the available Inventory up to Q. Hence, the anticipated cost transforms into,

(1.7)

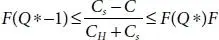

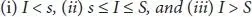

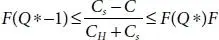

The optimal value of Q says Q* that minimizes TEC 1(Q)) is given by

(1.8)

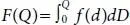

where

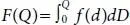

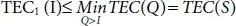

Since K is constant, minimum value of TEC’ (Q) ought to additionally accept via the same condition as given in equation

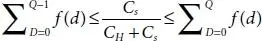

(1.9)

Since K is constant, minimum value of

And consequently Q* can even decrease TEC (Q).

Let us present two new control factors S and s, where S represents the extreme Stock stage and s signifies the reordered stage that is while the Stock degree tumbles to s, a request is situated to bring the Stock of Inventory items up to S.

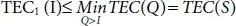

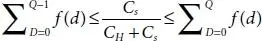

Thus, value of S= Q* and the price of s is determined by the relationship

(1.10)

As I the fundamental Inventory prior to starting the period, at that point to decide the request size to bring the available Inventory of articles as much as Q*, the ensuing three occasions might be examined.

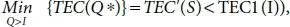

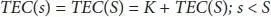

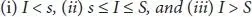

Case 1: If we start the length with I unit of Inventory and do not now buy or produce more prominent, at that point TEC (I) is the foreseen cost. In any case, on the off chance that we expect to purchase extra (Q-I) units in the event that you need to convey Inventory stage as much as Q*, at that point TEC’ (Q*) will include the set-up expense furthermore. Subsequently, for all I

(1.11)

That is, while Inventory stage arrives at S=Q*, request for Q-I units of Inventory might be put.

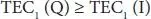

Case 2: For this situation, if I

(1.12)

This implies that no ordering substantially less costly than ordering. Thus Q*=I.

Case 3: If Q>I, at that point foreseen cost for a request up to Q could be extra than generally speaking foreseen cost if no structure is found, that is

(1.13)

Consequently, it is better not to put request for acquirement of things and afterward Q*=I.

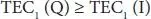

1.2.3.4 Numerical Examples

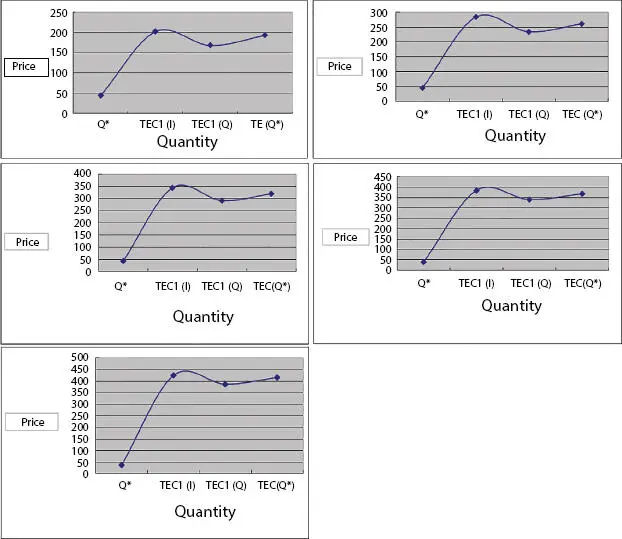

In framework to exhibit the proposed model, a Numerical model is settled with the accompanying Parameters value I=10, CH =0.53, Cs=Rs 5, C=2.5 and K=25. At that point get ideal arrangements are Q*= 45, TEC 1(I)=202.79, TEC 1(Q)=168.5, TEC (Q*) =193.5. Figured outcomes are demonstrated in Table 1.2.

Table 1.2 Optimal instantaneous demand solution of the order policy.

| Parameters |

Q* |

TEC1 (I) |

TEC1 (Q) |

(TEC (Q *) |

| I=10, CH = 0.53 CS = Rs 5 ,C = 2.5 andK 1 = 25 |

45 |

202.79 |

168.5 |

193.5 |

| I=10, CH = 0.54 CS = Rs 7 ,C = 3.5 andK 2 = 26.5 |

46 |

283.77 |

233.77 |

260.27 |

| I=10, CH = 0.51 CS = Rs 8.5 ,C = 4.5 andK 3 = 27.5 |

44 |

344.51 |

291.22 |

318.72 |

| I=10, CH = 0.52 CS = Rs 9.5 ,C = 5.5 andK 4 = 28.5 |

40 |

385.01 |

340.16 |

368.66 |

| I=10, CH = 0.52 CS = Rs 10.5 ,C = 6.5 andK 5 = 29.5 |

36 |

425.51 |

387.41 |

416.91 |

1.2.3.5 Sensitivity Analysis

Sensitivity analysis is performed in this section with respect to crucial parameter. We change the value parameter by Q*, TEC 1(I), TEC 1(Q), TEC (Q*) individually keeping different boundaries at their unique qualities and noticed its impact on ideal approach. This demonstrates that as the Ordered quantity increases (Q*), Expected cost Increases TEC(I), Optimum Stock achieve local minimum TEC(Q) decreases, Condition for Ordering TEC (Q*) is increments. Thus, the Sensitivity of the ideal outcome to little change in the Parameter esteem is inspected. Legitimate Inventory limit the Ordering cost of the multiplying. Proposed model be thing by taking various suppositions cost of Inventory value Parameters. The outcomes are presented in Table 1.2. Table 1.2is displayed in Figure 1.2.

Читать дальше