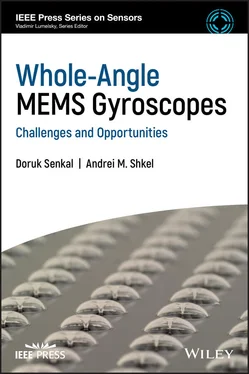

Doruk Senkal - Whole-Angle MEMS Gyroscopes

Здесь есть возможность читать онлайн «Doruk Senkal - Whole-Angle MEMS Gyroscopes» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Whole-Angle MEMS Gyroscopes

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 100

- 1

- 2

- 3

- 4

- 5

Whole-Angle MEMS Gyroscopes: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Whole-Angle MEMS Gyroscopes»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Whole-Angle Gyroscopes: Challenges and Opportunities

Whole-Angle Gyroscopes

Whole-Angle MEMS Gyroscopes — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Whole-Angle MEMS Gyroscopes», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

Table of Contents

1 Cover

2 List of Abbreviations

3 Preface

4 About the Authors About the Authors Doruk Senkal Dr. Senkal has been working on the development of Inertial Navigation Technologies for Augmented and Virtual Reality applications at Facebook since 2018. Before joining Facebook, he was working as a MEMS designer at TDK Invensense, developing MEMS Inertial Sensors for mobile devices. He received his PhD degree (2015) in Mechanical and Aerospace Engineering from the University of California, Irvine, with a focus on MEMS Coriolis Vibratory Gyroscopes, received his MSc degree (2009) in Mechanical Engineering from Washington State University with a focus on robotics, and received his BSc degree (2007) in Mechanical Engineering from Middle East Technical University. His research interests, represented in over 20 international conference papers, 9 peer‐reviewed journal papers, and 16 patent applications, encompass all aspects of MEMS inertial sensor development, including sensor design, device fabrication, algorithms, and control. Andrei M. Shkel Prof. Shkel has been on faculty at the University of California, Irvine, since 2000. From 2009 to 2013, he was on leave from academia serving as a Program Manager in the Microsystems Technology Office of DARPA, where he initiated and managed over $200M investment portfolio in technology development. His research interests are reflected in over 250 publications, 40 patents, and 3 books. Dr. Shkel has been on a number of editorial boards, most recently as Editor of IEEE JMEMS and the founding chair of the IEEE Inertial Sensors (INERTIAL). He has been awarded in 2013 the Office of the Secretary of Defense Medal for Exceptional Public Service, 2020 Innovator of the Year Award, 2009 IEEE Sensors Council Technical Achievement Award, 2008 Researcher of the Year Award, and the 2005 NSF CAREER award. He received his Diploma with excellence (1991) in Mechanics and Mathematics from Moscow State University, PhD degree (1997) in Mechanical Engineering from the University of Wisconsin at Madison, and completed his postdoc (1999) at UC Berkeley. Dr. Shkel is the 2020–2022 President of the IEEE Sensors Council and the IEEE Fellow.

5 Part I: Fundamentals of Whole‐Angle Gyroscopes

1 Introduction 1 Introduction Coriolis Vibratory Gyroscopes (CVGs) are mechanical transducers that detect angular rotation around a particular axis. In its most fundamental form, a CVG consists of two or more mechanically coupled vibratory modes, a forcing system to induce vibratory motion and a sensing system to detect vibratory motion. Angular rotation can be detected by sensing the energy transfer from one vibratory mode to another in the presense of Coriolis forces, Figure 1.1 . Historically, first examples of CVGs can be found in the Aerospace Industry, which were primarily used for navigation and platform stabilization applications. Later, advent of Micro‐electromechanical System (MEMS) fabrication techniques brought along orders of magnitude reduction in cost, size, weight, and power (CSWaP), which made CVGs truly ubiquitous. Today CVGs are used in a wide variety of civilian applications, examples include: Industrial applications, such as robotics and automation; Automobile stabilization, traction control, and roll‐over detection; Gesture recognition and localization in gaming and mobile devices; Optical image stabilization (OIS) of cameras; Head tracking in Augmented Reality (AR) and Virtual Reality (VR); Autonomous vehicles, such as self‐driving cars and Unmanned Aerial Vehicles (UAVs).

1.1 Types of Coriolis Vibratory Gyroscopes 1.1 Types of Coriolis Vibratory Gyroscopes CVGs can be divided into two broad categories based on the gyroscope's mechanical element [1]: degenerate mode (i.e. ‐axis) gyroscopes, which have – symmetry ( of 0 Hz), and nondegenerate mode gyroscopes, which are designed intentionally to be asymmetric in and modes ( ). Degenerate mode ‐axis gyroscopes offer a number of unique advantages compared to nondegenerate vibratory rate gyroscopes, including higher rate sensitivity, ability to implement whole‐angle mechanization with mechanically unlimited dynamic range, exceptional scale factor stability, and a potential for self‐calibration. Figure 1.1 Coriolis Vibratory Gyroscopes, in their simplest form, consist of a vibrating element with two or more mechanically coupled vibratory modes. Illustration shows a ‐axis gyroscope and its vibratory modes along ‐ and ‐axis.

1.2 Generalized CVG Errors 1.2 Generalized CVG Errors Gyroscopes are susceptible to a variety of error sources caused by a combination of inherent physical processes as well as external disturbances induced by the environment. Error sources in a single axis rate gyroscope can be generalized according to the following formula: (1.1) where is the measured gyroscope output, is scale factor error, is bias error, and is noise. Without loss of generality, for a whole‐angle gyroscope the error sources can be written as: (1.2) Figure 1.2 Micro‐rate integrating gyroscope (MRIG) architectures. where is the measured gyroscope output, corresponding to total angular read‐out, including the actual angle of rotation, errors in scale factor, bias, and noise.

1.3 Overview 2 Dynamics2.1 Introduction to Whole‐Angle Gyroscopes 2.2 Foucault Pendulum Analogy 2.3 Canonical Variables 2.4 Effect of Structural Imperfections 2.5 Challenges of Whole‐Angle Gyroscopes 3 Control Strategies 3.1 Quadrature and Coriolis Duality 3.2 Rate Gyroscope Mechanization 3.3 Whole‐Angle Mechanization 3.4 Conclusions

6 Part II: 2‐D Micro‐Machined Whole‐Angle Gyroscope Architectures 4 Overview of 2‐D Micro‐Machined Whole‐Angle Gyroscopes 4.1 2‐D Micro‐Machined Whole‐Angle Gyroscope Architectures 4.2 2‐D Micro‐Machining Processes 5 Example 2‐D Micro‐Machined Whole‐Angle Gyroscopes 5.1 A Distributed Mass MEMS Gyroscope – Toroidal Ring Gyroscope 5.2 A Lumped Mass MEMS Gyroscope – Dual Foucault Pendulum Gyroscope

7 Part III: 3‐D Micro‐Machined Whole‐Angle Gyroscope Architectures 6 Overview of 3‐D Shell Implementations 6.1 Macro‐scale Hemispherical Resonator Gyroscopes 6.2 3‐D Micro‐Shell Fabrication Processes 6.3 Transduction of 3‐D Micro‐Shell Resonators 7 Design and Fabrication of Micro‐glassblown Wineglass Resonators 7.1 Design of Micro‐Glassblown Wineglass Resonators 7.2 An Example Fabrication Process for Micro‐glassblown Wineglass Resonators 7.3 Characterization of Micro‐Glassblown Shells 8 Transduction of Micro‐Glassblown Wineglass Resonators 8.1 Assembled Electrodes 8.2 In‐plane Electrodes 8.3 Fabrication 8.4 Experimental Characterization 8.5 Out‐of‐plane Electrodes 8.6 Design 8.7 Fabrication 8.8 Experimental Characterization 9 Conclusions and Future Trends 9.1 Mechanical Trimming of Structural Imperfections 9.2 Self‐calibration 9.3 Integration and Packaging

8 References

9 Index

10 IEEE Press Series on Sensors

11 End User License Agreement

List of Tables

1 List of Abbreviations Table 1 Control system abbreviations. Table 2 Mechanical parameters of the resonator.

2 Chapter 5Table 5.1 Summary of design parameters.Table 5.2 As‐fabricated frequency symmetry of four devices.Table 5.3 Summary of design parameters.

3 Chapter 7Table 7.1 Comparison of wineglass dimensions obtained from analytical solutio...Table 7.2 Anchor loss analysis shows a large change in  for different stem di...Table 7.3 Sample design parameters for micro‐glassblown mushroom structure.Table 7.4 Sample design parameters for micro‐glassblown hemisphere.

for different stem di...Table 7.3 Sample design parameters for micro‐glassblown mushroom structure.Table 7.4 Sample design parameters for micro‐glassblown hemisphere.

Интервал:

Закладка:

Похожие книги на «Whole-Angle MEMS Gyroscopes»

Представляем Вашему вниманию похожие книги на «Whole-Angle MEMS Gyroscopes» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Whole-Angle MEMS Gyroscopes» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.