Ya Yang - Hybridized and Coupled Nanogenerators

Здесь есть возможность читать онлайн «Ya Yang - Hybridized and Coupled Nanogenerators» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Hybridized and Coupled Nanogenerators

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:3 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 60

- 1

- 2

- 3

- 4

- 5

Hybridized and Coupled Nanogenerators: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Hybridized and Coupled Nanogenerators»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Hybridized and Coupled Nanogenerators — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Hybridized and Coupled Nanogenerators», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

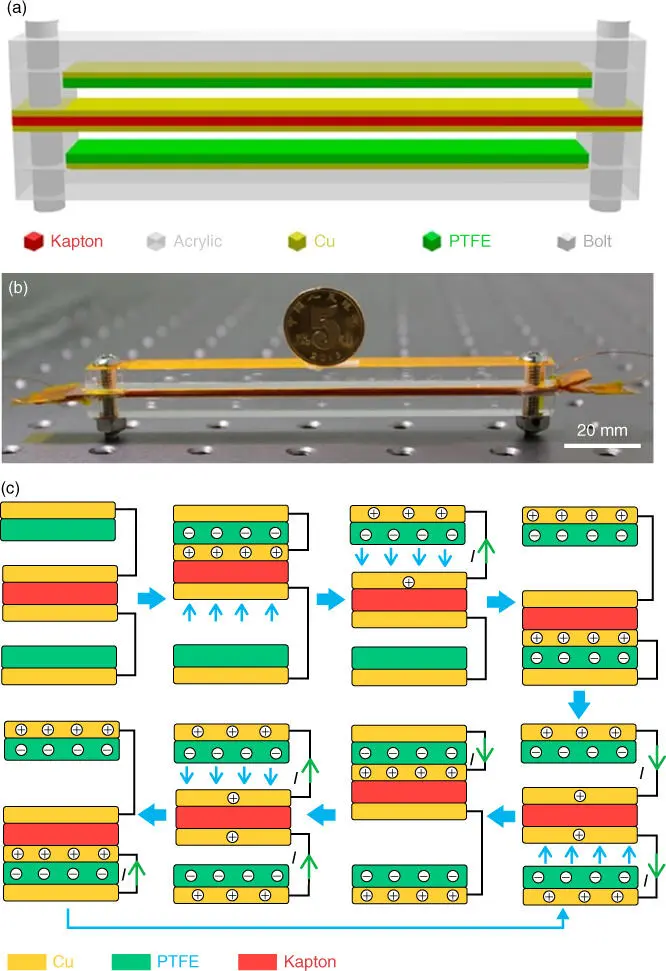

The working mechanism of the elasto‐aerodynamics‐driven TENG is schematically depicted in Figure 2.5c. Owing to couple triboelectrification and electrostatic induction, alternating electrons can flow between Cu electrodes. At the initial state, the TENG is in static condition, resulting in no output signals. When the Cu electrode makes contact with the top PTFE film because of wind‐induced vibration, electrons are transferred due to different triboelectric series, and their surfaces will respectively form positive and negative charges. When the distance between the Cu electrode and the PTFE film increases under the external force the balance is broken, leading to the generation of the current signal through an external load. The electrostatic‐induced charges disappear when a new balance is built between the Cu electrode and the PTFE film. In this state, the surface of the Cu electrode forms positive triboelectric charges, and the surface of the bottom PTFE film forms negative charges. Subsequently, the charges on the top electrodes and the bottom electrodes can flow respectively in the external circuits due to the electrostatic induction.

2.3.1.4 Others

To harvest wind energy in our living environment, Xie et al. produced a TENG based on a rotary‐driven mechanical structure, which consists of a shaft, a flexible rotor blade, and two stators [35]. The triboelectrification and electrostatic induction effects in this TENG can be generated by utilizing a hybridization of the contact‐sliding‐separation‐contact processes. Zhang et al. developed a single‐electrode cylindrical TENG to harvest wind energy, which consists of a cylinder, a cylinder tube coated with PTFE [36]. The electric energy generated by this TENG can be used to power wireless sensors. Bae et al. reported a flutter‐driven TENG based on a flexible flag and a rigid plate and studied three contact modes (single, double, and chaotic) to increase the performance of the TENG [37]. Ren et al. designed a coaxial rotatory freestanding TENG, which consists of a stator and a rotator. The stator was made of an acrylic column coated with polyvinylidene fluoride (PVDF) nanofibers membrane, and the rotator was made of another acrylic tube with Al tapes [38].

The TENG arrays could enhance the efficiency of harvesting wind energy. Quan et al. reported double‐side‐fixed TENG arrays based on the coupling of triboelectric frication and electrostatic induction. The TENG arrays were connected in parallel by copper wires. These TENGs consist of top and bottom PTFE/Ti/Al patches and a vibrational Al/Ti/Kapton/Ti/Al film [39]. To enhance the performance and reduce a typical rigid friction of common TENG for harvesting wind energy, Wang et al. reported a composited structure, which consists of an anemometer TENG based on freestanding mode and a wind vane TENG based on single‐electrode mode [40]. The anemometer TENG was made of wind cups, rotator, and stator. Wind energy harvested through the wind cups can be used to drive the rotator. The FEP film used as a triboelectric surface was coated on the rotator. The wind vane TENG was made of a vane connected with a pie‐shaped rotator and a compass coated with Cu electrodes.

Figure 2.5Diagram of the elasto‐aerodynamics‐driven TENG. (a) Schematic diagram of the TENG. (b) The front view of the TEG. (c) Sketches illustrating the electricity generation process in the elasto‐aerodynamics‐driven plate‐based TENG.

Source: Reproduced with permission from Wang et al. [34]. Copyright 2015, American Chemical Society.

Wind‐driven generators normally can harvest wind in a single direction, which reduces the efficiency of wind energy utilization. To solve this problem, Zhang et al. developed a flexible and transparent TENG, which can harvest natural wind in discretional blowing directions [41]. The TENG was made of massive freestanding polymer strips similar to a forest morphology. When the wind blows, the strips comprised of indium tin oxide (ITO) with polyethylene terephthalate (PET) thin film could sway independently. Harvesting wind energy at a high altitude is difficult for normal wind‐driven generators. Recently, Zhao et al. reported a woven TENG flag based on the interlaced interactions between the Kapton film and a conductive cloth, realizing collection of high‐altitude wind energy [42]. The conductive belts were made of polyester textiles coated with Ni and Kapton film‐sandwiched Cu belts.

2.3.2 Materials

Currently, advanced materials, such as cellulose nanocrystals (CNCs), bionic materials, and nanowires, have become the most inspiring point for TENGs, which can increase the electric or mechanical performances of the devices. To meet the exceptional properties and demands, reasonable design of various materials is indispensable.

2.3.2.1 Cellulose

Cellulose nanomaterials have many outstanding advantages including high surface area, light weight, and excellent mechanical properties, resulting in an important role in diverse applications [43–47]. Plant cell walls have a great deal of cellulose, a fibrous water‐loving polymer, which is generated through the plant cellular growth process and cellulose biogenesis. Some creatures, such as fungi, invertebrates, and algae, also have cellulose. The entire process for forming cellulose needs van der Waals force and hydrogen bonds. There are two parts (crystalline and amorphous parts) in cellulose fibrils. CNCs can be generated by insulating crystalline domains, and cellulose nanofibrils (CNFs) can be produced through mechanical interventions. Both of them are nanoscale lateral dimensions, which can realize many outstanding advantages, including low density, flexibility, and large aspect ratio [48–50].

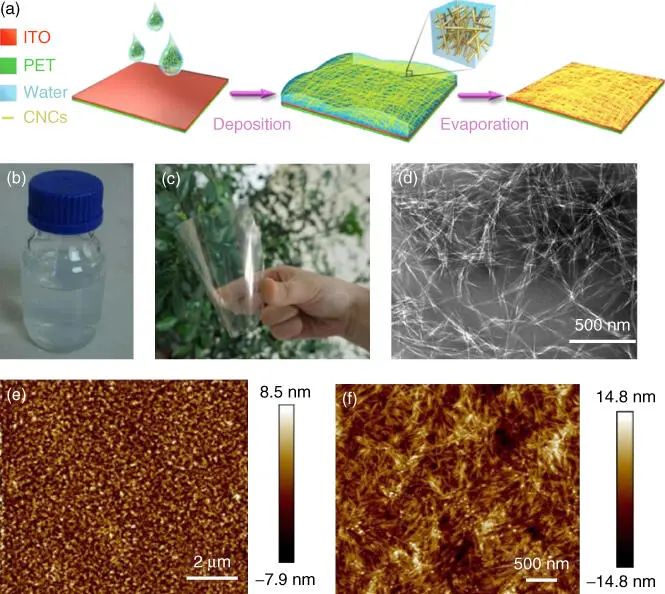

Chen et al. developed a transparent TENG, where CNCs were used as the positive triboelectric materials because of their prominent excellent mechanical properties and nano‐sized slender structures [51]. CNCs in the bleached kraft pulp can be produced by acid hydrolysis method. Figure 2.6b shows the prepared CNCs suspension with high transparency. An ITO film was fixed on a PET substrate, and the suspension was dropped on the film as shown in Figure 2.6a. After the water was evaporated at room temperature, the CNC film could completely cover the ITO film. The prepared CNC/ITO film possesses great transparency, as illustrated in Figure 2.6c. Transmission electron microscopy (TEM) images of the CNCs show the scale of the prepared CNCs, with 50–300 nm length and 3–5 nm width ( Figure 2.6d). Figure 2.6e shows the atomic force microscopy (AFM) image of the ITO film. The AFM image of CNC/ITO presents high surface roughness. When the surface of the CNC film makes contact with the FEP film under the external force, the electrons could flow from the CNC film to the surface of the FEP film because the CNC film holds a positive position in the triboelectric series.

Figure 2.6The CNCs/ITO film. (a) The schematic for preparing the CNCs/ITO films. (b) Photograph of the CNCs suspension. (c) The prepared CNCs/ITO electrode. (d) TEM image of the prepared CNCs. (e) AFM image of the ITO substrate. (f) AFM image of the CNCs/ITO substrate.

Source: Reproduced with permission from Chen [51]. Copyright 2018, Elsevier.

Bacterial cellulose (BC) has been widely used due to outstanding advantages such as high elastic modulus, good degree of polymerization, and biocompatibility. Kim et al. used bacterial nanocellulose film as the triboelectric material in the TENG. The bacteria can generate the BC pellicle in a gel state. The uniform BC film was prepared by dissolving the BC pellicle at a specified concentration [52]. CNFs generated from nanosized cellulose fibrils are proverbially used in modern electronic devices due to their desirable surface roughness and electrical properties. Yao et al. produced biodegradable CNF films with nanostructured surface and applied them in the TENG [53]. The CNF hydrogel was produced into a CNF film by a treating process, where wood pulp was oxidized and then mechanically homogenized. By filtering and the drying processes, the CNF hydrogel can be transformed to transparent and flexible CNF thin films. When contacted with the FEP film, the surface of the CNF film could hold positive triboelectric charges due to its very positive position on the triboelectric series. Single cellulose films are fragile and volatile. To conquer these problems, Chandrasekhar et al. developed a cellulose/polydimethylsiloxane (PDMS) film in the TENG [54]. Composite films with irregular surface roughness were fabricated by solidifying the mixed solution of cellulose powders and PDMS on the sandpaper template. The content of cellulose could affect the output performance of the TENG. Peng et al. fabricated the composite film with PDMS and CNC flakes and found that the cellulose can increase the output performance of the TENG due to the favorable dielectric property [55].

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Hybridized and Coupled Nanogenerators»

Представляем Вашему вниманию похожие книги на «Hybridized and Coupled Nanogenerators» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Hybridized and Coupled Nanogenerators» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.