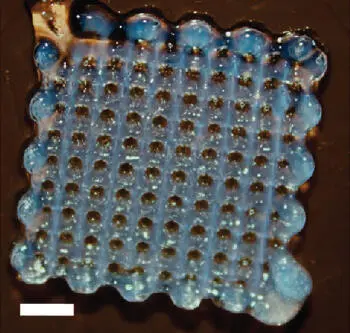

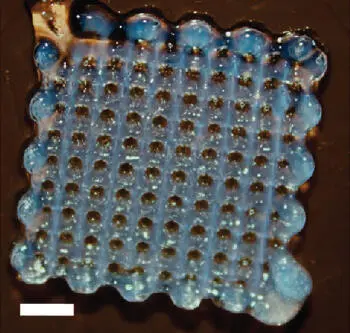

Figure 2.3Top view of 3D printed hyaluronic acid (6% w/v) and Dex‐HEMA (10% w/v) hydrogel. The scale bar represents 25 mm.

Source: Reprinted with permission from Pescosolido et al. [161]. Copyright 2011, American Chemical Society.

Xanthan gum is other polyanionic polysaccharide often used as an attractive material for the fabrication of hydrogels. Generally, xanthan is combined with other polysaccharides to improve gelation characteristics since by itself xanthan is only able to produce transient weak gels. Recently, a hydrogel made from xanthan and galactomannan from the seeds of the Brazilian native tree Schizolobium parahyba was reported by Koop et al. [162]. The binary hydrogel was loaded with curcumin for topical and cutaneous wound applications. The results revealed that such hydrogels allowed prolonged exposure to the skin without any irritation and the possibility to treat skin diseases such as psoriasis. In other study, xanthan was chemically crosslinked with starch to perform hydrogels for drug delivery applications [163]. Starch–xanthan gum hydrogels exhibited selective permeability depending on drug charges and revealed to be a promising material for controlled release of several drugs.

As described, a wide and diverse range of polysaccharides have been used as attractive materials to design and fabrication of hydrogels [139,141]. Among others, remarkable properties of microbial polysaccharides make them promising materials for different biomedical applications including tissue engineering, drug delivery, and cell therapies.

2.5 Bionanocomposites Based on Microbial Polysaccharides

MNPs are valuable nanostructures with proven applicability in areas such as molecular diagnostics and biomedicine [164,165]. Their unique physical properties can be tailored based on the size and composition of the inorganic material that can include noble metals (e.g. gold, silver), magnetic elements (e.g. iron, cobalt), or semiconductors (e.g. carbon nanotubes) [164]. The encapsulation of such MNPs in an inorganic (e.g. ceramic) or organic (e.g. biopolymeric) matrix generates multiphase materials (nanocomposites), wherein the synergetic effect between the components adds novel features to this material. Over the past years, the interest in the study and development of nanocomposites has grown considerably due to their valuable physical properties and countless applications that range from packaging to biomedicine [166].

Nanocomposites can have different types of matrices: ceramic, metallic, or polymeric. The properties and functionalities of these matrices can be enhanced by using diverse nanostructures such as ceramics, carbon nanotubes, metal nanoparticles, or even active biological substances [166]. Giving this, nowadays it is possible to produce nanocomposites for all sorts of applications. One good example is the production of a biocompatible hydrogel with conductive properties to be used in biomedicine. By using a polymer‐based matrix (e.g. chitosan) incorporated with a conductor inorganic material (e.g. carbon nanotubes), it is possible to produce a nanocomposite with potential use in the design of electrochemical biosensors [82,167]. Another great example is the nanocomposites produced with magnetic nanoparticles. These MNPs have their potentialities well established in the medical field. Usually, these applications take advantage of three unique features inherent to magnetic nanoparticles. These properties are the field‐induced mobility (for the development of drug delivery systems), their ability to modify magnetic relaxation times of surrounding molecules (for magnetic resonance imaging [MRI] applications), and their capacity to heat under an alternative magnetic field (for hyperthermia applications) [168,169]. The encapsulation of magnetic nanoparticles in a polymeric matrix (e.g. polyacrylamide) creates a thermoresponsive hydrogel. If this nanocomposite also contains a pharmaceutical drug, it could be used as a controlled release system. By applying an alternative magnetic field, the nanoparticles will increase their temperature changing the hydrogel structure to a more flexible state, allowing the easier delivery of the pharmaceutical substance [82]. In the previous examples, it has been established the importance of using polymeric matrices to produce nanomaterials with enhanced properties, as well as the potentialities of using these nanocomposites for medical applications.

More recently, it has been studied the use of biological polymers in the production of nanocomposites (bionanocomposites). The wide diversity of available natural polymers with distinct structures and properties has driven the interest toward the development of novel biopolymer nanocomposites with unique or improved functionalities. Unlike synthetic polymers, biopolymers have inherent favorable interaction with living systems [78]. Moreover, due to their chemical and structural diversity, biopolymers can provide excellent matrices for incorporation of different active substances (e.g. MNPs, hydrophilic and hydrophobic drugs), being more sustainable and having limited environmental impact due to their inherent biodegradability [80].

As previously mentioned, microbial polysaccharides have unique properties suitable to a wide range of applications. Some of these biopolymers are also known to have interactions with biological systems. These properties are usually associated with the composition of the polysaccharide. For instance, FucoPol is a biopolymer with potential antitumor and anti‐inflammatory properties due to its high fucose content. Fucose is a rare sugar with reported anticarcinogenic, antiaging, and anti‐inflammatory properties [4]. For these reasons, microbial polysaccharides can be used in the development of bionanocomposites not only as a matrix material due to their ability to form structured materials (e.g. hydrogels and films) but also as an active substance. This duality presented by the polysaccharides is an important feature for the development of bionanomaterials especially for biomedical applications [168,170].

Lately, the use of bionanocomposites with polysaccharides in several fields ranging from the degradation of pollutants to the development of hyperthermia agents and targeted delivery systems has been studied ( Figure 2.4). For these types of applications, the biodegradability, the biocompatibility, and the biological response are important properties that can be easily attainable by using polysaccharides (especially from microbial origin) [172]. In Table 2.2, the use of distinct polysaccharides (all attainable through microbial production) and different MNPs for the development of nanocomposites for several applications has been shown. It is curious that the use of Au and Ag nanoparticles is usually associated with the production of nanocomposites with anticancer and antibacterial properties, respectively. Meanwhile, Fe 3O 4nanoparticles are frequently related to the development of nanomaterials for drug delivery systems, hyperthermia, and contrast agents for MRI. Given this, the potentialities of the use of bionanocomposites with microbial polysaccharides especially in biomedicine remain well established.

Figure 2.4Microbial polysaccharide‐based nanocomposites with metal nanoparticles for biotechnological applications.

Source: Adapted from Manivasagan and Oh 2016 [81] and Escárcega‐González et al. 2018 [171].

Table 2.2Bionanocomposites containing polysaccharides and their applications.

Читать дальше