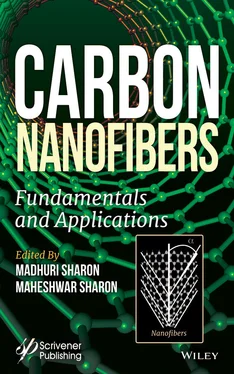

1 ...6 7 8 10 11 12 ...23 Because of their low-cost, dye-sensitized solar cells (DSSC) are being thought of to replace silicon solar cells. DSSC consists of a photoanode and a counter electrode separated by a redox electrolyte (iodide/triiodide). CNFs are highly stable against electrochemical corrosion in either alkaline or acidic media, hence are found to possess significant catalytic activity and power conversion efficiency in DSCs. This material is expected to replace expensive counter electrode made of noble metals like platinum.

CNF can be used as catalyst due to its high specific surface area, high chemical resistance, outstanding electrical properties, and suitable mechanical properties. Because of good electrical properties, it is developed for high loaded active enzymes and for fast kinetics at electrode surface, especially for enzymatic cathodes in biofuel cell devices. Carbon of CNF acts both as catalyst and adsorbent for the catalytic oxidation of NO into NO2 or reduction of NO into N2.

In developing electrodes for fuel cell, it is essential to replace platinum with some other materials which are inexpensive. CNFs loaded with nickel, iron and nitrogen are found to be suitable material for use as an electrode in alkaline fuel cell.

Microbial fuel cell (MFC) is a bio-electrochemical cell that uses microorganisms to utilize organic substrates at anodes to generate electricity. For this purpose, it is necessary to develop biocompatible electrode materials with high surface area and long-term stability to support the maximum growth of bacteria and enhance electron transfer rate. CNFs are finding their use as anode in MFC [18].

CNFs have generated interest in the area of sensors and biosensors because of their functionalization ability, electrochemical property, mechanical flexibility, and biocompatibility. They have exhibited a good response for developing glucose biosensor. Metal-loaded CNFs are gaining in popularity in developing biosensors. For example, palladium-loaded CNFs exhibit good electrochemical catalytic activities for determining dopamine (DA), uric acid (UA), and ascorbic acid (AA). These three chemicals can be determined simultaneously from their mixture because of their difference in overpotential [19].

CNFs are used as good adsorbent material especially in the field of adsorption/separation because of their high specific surface area and high porosity. Removal of dissolved impurities, such as dyes and metals present in drinking and industrial water, is being tried using CNFs. There are several chapters devoted to different applications of CNF presented in this book.

1.6 Health Hazards of CNF

Though many studies are being conducted with CNFs, some studies have indicated that there are health hazards associated with CNFs especially due to their sizes [20, 21]. One of the hazards associated with CNF is that it is expected to cause respiratory damage such as pulmonary inflammation, granuloma, and fibrosis. These effects are observed with mice. There seem to be no studies available on its effect on human beings. However, it is proposed to wear some type of mask when working with CNF so that it is not inhaled. Sharon and his research team have observed that CNF of a particular band gap if spread over skin affected by cancer cells, and simultaneously exposed to visible light, can kill cancerous cells, suggesting that this material can be used in dermatology for killing the growth of cancer cells grown over skin. However, this experiment was done with mice only [22–25].

In this chapter an effort was made to discuss the various aspects of carbon fibers and carbon nanofibers, including their synthesis, properties and applications. An effort was also made to explain the basic differences between carbon fibers, carbon nanofibers and carbon nanotubes.

1. R. Millington, of H.I. Thompson Fiberglas Co. (US Patent No. 3,294,489) Process for producing a high carbon content (99%) fibre using rayon as a precursor, 1960.

2. Sharon, M., Apte, P.R., Purandara, S.C., Zacharia, R., Application of the Taguchi Analytical Method for optimization of Effective parameters of the chemical vapour deposition controlling the production of nanotube/ nanobeads. J. Nanosci. Nanotechnol ., 5, 2, 288–295, 2005.

3. Sharon, M., Mishra, D.K., Bejoy, N., Application of Taguchi Methodology for Optimization of Parameters of CVD Influencing Formation of a Desired Optical Band gap of Carbon Film. Carbon Sci ., 6, 2, 96–100, 2005.

4. Debabrata, P., Synthesis of carbon nanomaterials and their applications, PhD thesis, IIT Bombay, Powai, Maharashtra, India, 2003.

5. Hughes TV, Chambers. Manufacture of 0 N Filaments, No. 405,480. v I Patented June 18, 1889. //TFH5,. 74 2772 anew. ww Z 42 3}.

6. Endo, M., Grow carbon fibers in the vapor phase. Chemtech , 18, 568–576, 1988.

7. Iijima, S., Helical microtubules of graphitic carbon. Nature , 354, 56–58, 1991.

8. Afre, R.A., Soga, T., Jimbo, T., Kumar, M., Ando, Y., Sharon, M., Growth of vertically aligned carbon nanotubes on silicon and quartz substrate by spray pyrolysis of a natural precursor; turpentine oil. Chem. Phys. Lett ., 414, 1–3, 6–10, 2005.

9. Finegan, I.C., Tibbetts, G.G., Glasgow, D.G., Ting, J.M., Lake, M.L.J., Surface treatments for improving the mechanical properties of carbon nanofiber/ thermoplastic composites. Mater. Sci ., 38, 3485, 2003.

10. Kumar, S., Doshi, H., Srinivasarao, M., Park, J.O., Schiraldi, D.A., Fibers from polypropylene/nano carbon fiber composites. Polit. Commun ., 43, 170, 2002.

11. Tibbetts, G.G. and McHugh, J.J., A review of the fabrication and properties of vapor-grown carbon nanofiber/polymer composites. Mater. Res ., 1999, 14, 1999.

12. Sadeghian, R., Minaie, B., Gangireddy, S., Hsiao, K.-T., In 50th International SAMPE Symposium Proceedings , Long Beach, CA, May 1–5, 2005.

13. Li, B., Wood, W., Baker, L., Sui, G., Leer, C., Zhong, W.H., Synergistic effects of hybrid graphitic nanofillers on simultaneously enhanced wear and mechanical properties of polymer nanocomposites, Polym. Sci. Eng ., 210, 50, 1914.

14. Peng, H., Liu, X., Wang, R., Jia, F., Dong, L., Wang, Q., Emerging nanostructured materials for musculoskeletal tissue engineering. Nanomater ., 32, 803, 2006.

15. Lafdi, K. and Matzek, M., In 48th International SAMPE Symposium Proceedings , Long Beach, CA, May 11–15, 2003.

16. Koo, J., Polymer Nanocomposites: Processing, Characterization and Applications , McGraw-Hill, Boston, 2006.

17. Zammarano, A.M., Kramer, R.H., Harris, R., JR., Ohlemiller, T.J., Shields, J.R., Rahatekar, S.S., Lacerda, S., Gilman, J.W., Flammability reduction of flexible polyurethane foams via carbon nanofiber network formation. Polym. Adv. Technol ., 19, 588, 2008.

18. Patil, S.A., Chigome, S., Hagerhall, C., Torto, N., Gorton, L., Electrospun carbon nanofibers from polyacrylonitrile blended with activated ographitized carbonaceous materials for improving anodic bioelectrocatalysis. Bioresour. Technol ., 132, 121, 2013.

19. Huang, J., Liu, Y., Hou, H., You, T., Simultaneous electrochemical determination of dopamine, uric acid and ascorbic acid using palladium nanoparticle-loaded carbon nanofibers modified electrode. Biosens. Bioelectron ., 24, 632, 2008.

20. Wu, M., Wang, Q., Liu, X., Liu, H., Biomimetic synthesis and characterization of carbon nanofiber/hydroxyapatite composite scaffolds. Carbon , 51, 335, 2013.

21. Yang, Q., Sui, G., Shi, Y.Z., Duan, S., Bao, J.Q., Cai, Q., Yang, X.P., Osteocompatibility characterization of polyacrylonitrile carbon nanofibers containing bioactive glass nanoparticles. Carbon , 56, 288, 2013.

Читать дальше

![Carbon - Посох с проблемами [калибрятина, куски]](/books/397599/carbon-posoh-s-problemami-kalibryatina-kuski-thumb.webp)

![Carbon - Ключ от магии, или Нимфа по вызову [СИ]](/books/417919/carbon-klyuch-ot-magii-ili-nimfa-po-vyzovu-si-thumb.webp)

![Carbon - Девушка с Косой [СИ]](/books/427728/carbon-devushka-s-kosoj-si-thumb.webp)