1.3.4 Selection of Variable Parameters for Growth of CNF

Variable parameters of pyrolysis under the CVD units are: precursor (oil, solid materials like plant materials, camphor, etc.), temperature ( Figure 1.8A1and A2), type and size of catalyst (usually nickel, iron and cobalt), carrier gas (argon, nitrogen, etc.), reactive gas (hydrogen), and duration of pyrolysis. Due to the large number of variables, it becomes very time-consuming to reach a suitable condition to obtain the desired type of CNF.

It is advisable that one should adopt the Taguchi method, which can provide information of effective variables to produce the required type of CNF [1–3]. For example, with 4 variables (requires 24 experiments) one needs to carry out only 9 sets of experiments; whereas, with 6 variables (requires 720 experiments) one needs to carry out only 16 sets of experiments.

1.3.5 Epitaxial Growth of Aligned CNF

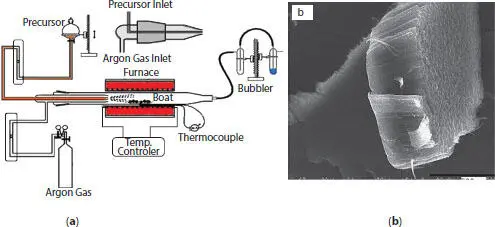

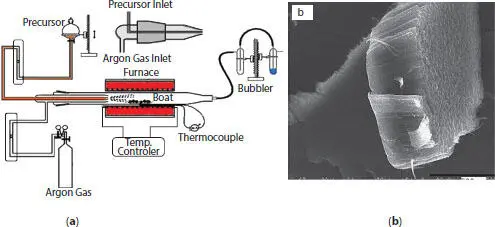

Afre et al . [8] have developed a CVD with spray techniques ( Figure 1.9A) to get epitaxial growth of aligned, continuous ( Figure 1.9B), catalyst-free carbon nanofiber from vapor of turpentine oil. Aligned CNF possesses properties like high mechanical strength, high directional electrical conductivity, and high thermal conductivity. The main difference between the CVD unit described in Figure 1.8and 1.9is the inclusion of a spray facility so that solution containing precursor and the catalyst sprays its liquid in the furnace like a cloud of material.

1.3.6 Mechanism of CNF Synthesis

There are different mechanisms suggested to explain the role of catalyst but none of them can explain why CNFs are formed over the entire reaction tube in a larger amount than the amount of catalyst used for the purpose. The author of this chapter suggests that vapor of precursor at high temperature breaks down into lower very reactive carbon fragments and this decomposition is catalyzed by the catalyst. These reactive fragments move around the furnace ( Figure 1.8A2) with the help of the carrier gas. Since these fragments are highly reactive, they recombine to give CNF. The process of recombination giving the product depends upon the variable conditions used for the synthesis of CNF. The nature of CNF formed thus depends upon variables like temperature, the flow rate of carrier gas, etc. It is for this reason one finds deposition of CNF not only in the boat ( Figure 1.8B2) but throughout the quartz tube ( Figure 1.8C). Moreover, the amount of CNF formed are far in excess of the amount of catalyst used for the purpose.

Figure 1.9 (a) typical sketch of CVD unit with a spray system and (b) the aligned carbon nanofibers produced from this process using turpentine oil.

1.4 Properties of CNF and Its Composites

Electrical conductivity in CNF/polymer composites depends upon the nature of the network and their alignment in the matrix. Therefore, for good electrical conductivity a good fiber dispersion and the continuation of the network of carbon nanofibers is necessary. Also, by controlling the loading amount of CNF in the composite different electrical resistivity values can be achieved. CNF/polymer composite can increase the tensile strength (gain of 50 to around 300%), compression strength (50–100%), Young’s modulus (almost 100%), inter-laminar shear strength (with 1% CNF increases in the range of 20–50%), fracture toughness (with 1% CNF increases in the range of 30–50%), and vibration damping of the base polymer. These improvements depend upon the nature of polymer, extent of dispersion, etc. [9–15]. Thermal conductivity of CNF with 20 wt% epoxy resin has been observed to increase from 0.2 W/m-K to 2.8 W/m-K [15]. CNF composite with thermoplastic material is found to retard fire properties like delay in burning when exposed to flame and slow heat transmission [16, 17]. Polymeric composites with carbon nanofibers have shown substantially lower coefficients of thermal expansion as compared to graphite. Details of CNF and its composites are presented in Chapter 4of this book.

Some of the applications of CNF are enumerated here:

Scientists, after understanding the properties of carbon fibers, have started using this material in various engineering applications to reinforce concrete, replace steel with carbon fibers, as material for bridge work, etc. CNFs are being applied or are thought to apply for strengthening of structures with carbon fiber composites in precast concrete and plastic, and fiber-cement. The traditional method of strengthening the reinforcement of brick is by utilizing steel clamps, which provide strength but also become heavy and are prone to corrosion. CNFs are being thought of to use in place of steel to get almost the same strength. Carbon fibers in precast concrete has also become popular since 2003. Carbon fiber grid reinforcement is applied in the wall panel face, which allows the use of less concrete, reducing weight and raw material.

CNF composites with a conductive polymer, polypyrrole (PPy), in N,N-dimethylformamide (DMF) solvent increases its strength.

The non-corrosive nature of carbon fibers prevents the rusting and staining which otherwise occur with steel reinforcing. Carbon fiber composites have low thermal conductivity, thus reducing the transfer of heat or cold from outside to inside. Carbon fiber composites used for building works provide the benefit from long-term energy savings. CNF is used in bridge construction because CNF-reinforced plastic provides reduction in bridge weight and economy of lifting equipment. Carbon fibers possess the property of repelling water, hence are used by mixing with grits and coal tar to give more life to the road.

CNFs are used as additive for anode and cathode materials in energy conversion and storage systems because they possess properties like good chemical stability, thermal stability, and electrical conductivity, high specific surface area and good charge transport properties.

CNF is used for the delivery of therapeutic drugs. It has been proposed that when a needle-shaped carbon nanofiber is loaded with therapeutic drugs and embedded into an elastic material (which can be inflated to form a balloon) and inserted next to the diseased site, the needle-shaped CNF penetrates the diseased cell and delivers the therapeutic drugs.

Since CNF has large surface area and good electrochemical properties, it is observed that it increases the capacity of lithium battery more than graphite. CNF is used to improve overall energy capacity and cycling stability of anode material of lithium-ion battery. Because of its reversible electrochemical properties, it increases good charging/ discharging cycles of lithium battery. Metal/CNF composites, like carbon/TiO2, Carbon/SnO2, etc., have been found to enhance the capacity of lithium-ion battery.

CNF is used to develop gas mask sensor because it changes its color after absorbing chemical.

Since the electrical conductivity in CNF is highest along its length, it can be used as electron field emitter if aligned CNF is grown along its length.

Supercapacitors (electric double-layer capacitors) are gaining in popularity because they can provide high energy density and better power density than normal batteries. There has been increasing interest in the use of porous carbon nanofibers to develop supercapacitors because of their higher specific surface area (1200 m2/g or more). The electrode (e.g., CNF/V2O5 composite) has given specific capacitance of 150 F/g and energy density of 18.8 W h kg-1 over a power density range of 400–20,000 W kg-1. Number of operating cycles with CNF supercapacitor has also been found in the range of 2000 cycles.

Читать дальше

![Carbon - Посох с проблемами [калибрятина, куски]](/books/397599/carbon-posoh-s-problemami-kalibryatina-kuski-thumb.webp)

![Carbon - Ключ от магии, или Нимфа по вызову [СИ]](/books/417919/carbon-klyuch-ot-magii-ili-nimfa-po-vyzovu-si-thumb.webp)

![Carbon - Девушка с Косой [СИ]](/books/427728/carbon-devushka-s-kosoj-si-thumb.webp)