1 ...6 7 8 10 11 12 ...21

| Sensor type |

Main specifications |

References |

| Barcode |

Optical laser reading identifying only type of itemOnly read<20 of characters of data capacity |

[16, 17] |

| QRcode |

Optical laser reading identifying only type of itemOnly readUp to 7089 characters of data capacity |

[17, 18] |

| RFID |

Radio frequency detection system100–1000 characters of data capacityRead and writeStandards: 125–134 kHz (LF); 13.56 MHz (HF); 866–915 MHz (UHF); 2.45–5.8 GHz (microwave)Active tags (100 m reading distance, 64 byte–32 KB of memory capacity)Passive tags (1 m reading distance, 48 byte–2 KB of memory capacity) |

[16, 17,19–21] |

| NFC |

Distance of communication: few cmTechnology: RFID basedFrequency: 13.56 MHzCommunication: two way |

[21] |

| iBeacon |

Bluetooth Low‐Energy (low power consumption)1 m ± 70 m wireless range |

[22, 23] |

NFC, near field communication; RFID, radio frequency identification.

Table 1.4 Main specifications of sensor transmission protocols.

| Standard |

Main specifications |

References |

| ZigBee |

WirelessIEEE802.15.4 standardWPANFrequencies: 868 MHz (Eu); 915 MHz (US); 2.4 GHz30−100 m wireless rangeNetwork type: star, mesh, cluster tree, peer to peerCapacity: 250 Kbit s −1 |

[24–26] |

| WiFi |

WirelessIEEE802.11 standardWireless local area networkFrequencies: 2.4–5.4 GHz1 km wireless rangeCommunication type: point to multipointCapacity: 54 Mbit s −1 |

[26] |

| Bluetooth |

WirelessIEEE802.15.1 standardWPAN networkFrequencies: 2.45 GHz1–100 m wireless rangeCommunication type: point to multipointNetwork type: starController: system on chipData rate: 1 Mbit s −1Capacity: 723.1 Kbit s −1(versions 1.1 and 1.2); 3 Mbit s −1(version 2.0)Bluetooth V4.0 |

[21, 24] |

| RS‐232 |

WiredLAN/PAN networkCommunication type: point to pointNetwork type: busCapacity: 75 bit s −1–115.2 Kbit s −1. |

[27] |

| USB |

WiredLAN/PAN networkCommunication type: point to pointNetwork type: tree, busCapacity: 12 Mbit s −1(version 1.1); 480 Mbit s −1(version 2.0); 4800 Mbit s −1(version 3.0) |

[28] |

| Ethernet |

WiredLAN networkCommunication type: point to pointNetwork type: star, busCapacity: 10 Mbit s −1–10 Gbit s −1 |

[29] |

| ZWAVE |

Radio frequency technologySub‐GHz communications (900 MHz)Mesh networkNo coordinator nodeMaster/slave architectureData rates: 9.6/40/100 Kbit s −1 |

[24] |

| Fifth Generation (5G) |

Cellular network standardHigher throughputLower latencyArtificial intelligence capabilitiesVideo real‐time processing |

[24] |

WPAN, wireless personal area network.

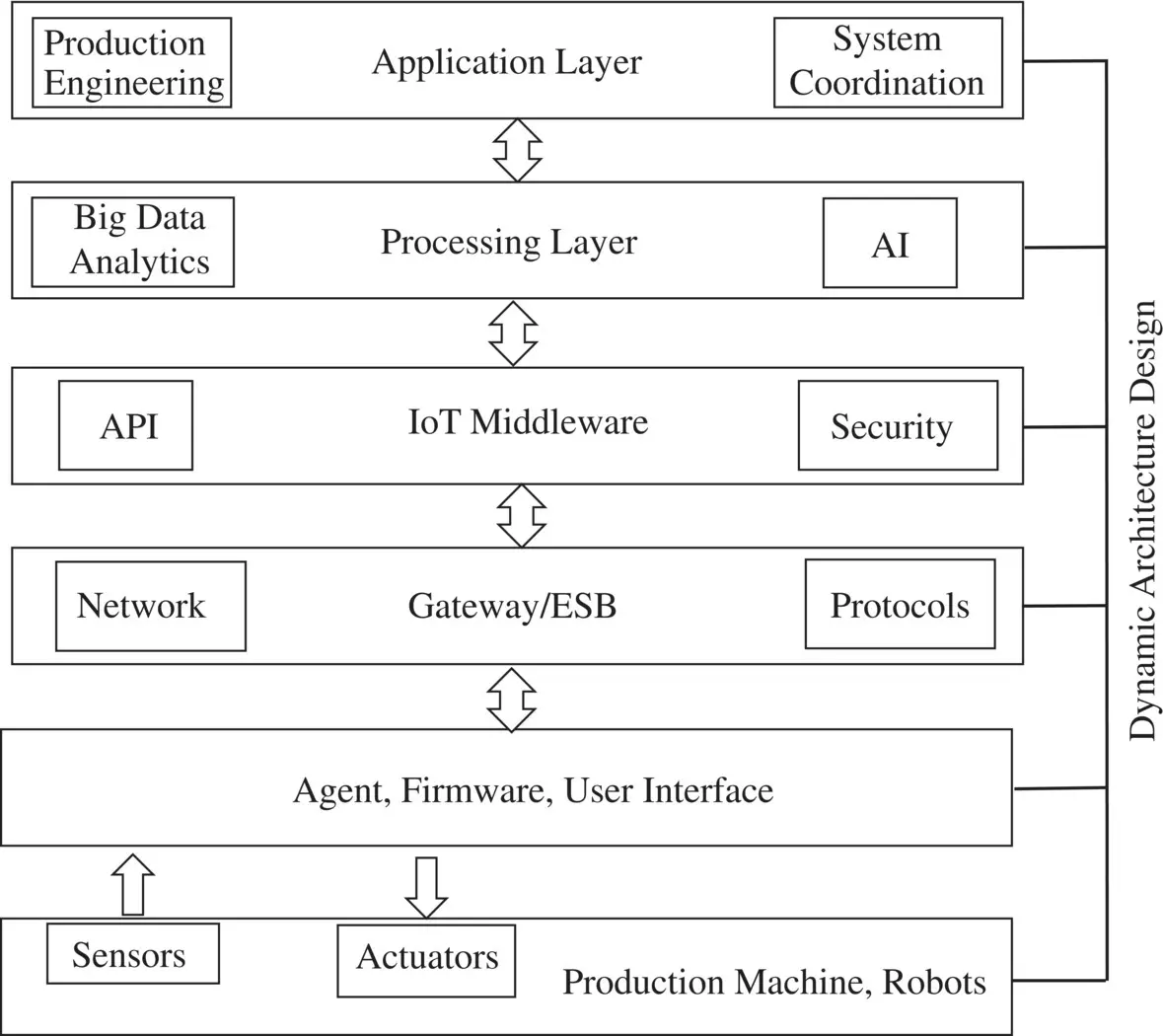

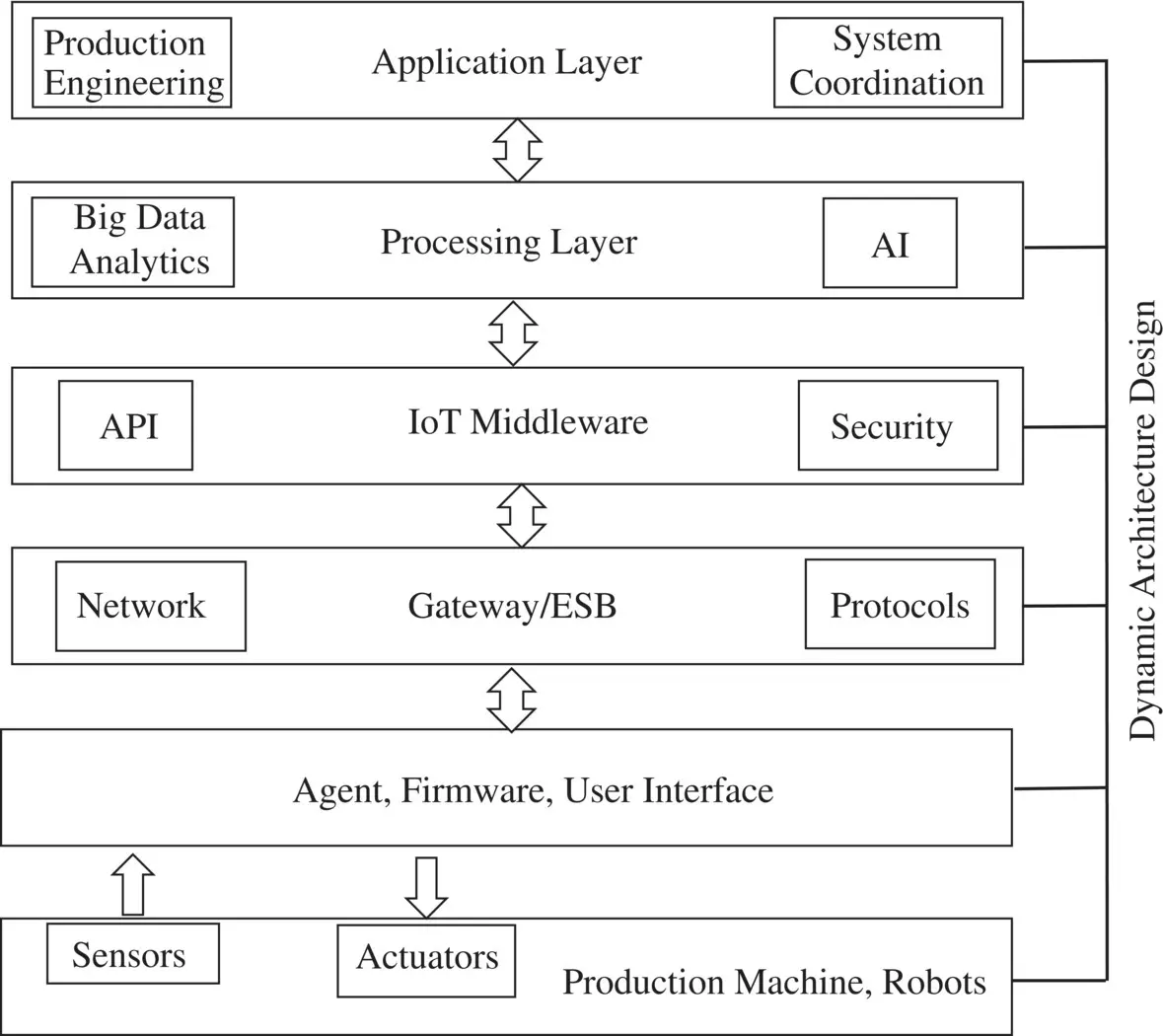

The information levels of a dynamic information system, allowing the upgrade from Industry 4.0 to Industry 5.0 production, is interconnected as in Figure 1.3, where the following six main layers are distinguished:

Sensor and actuator layer.

Agent, firmware and user interface layer.

Gateway layer.

IoT middleware.

Processing layer.

Application layer.

Figure 1.3 Layers of technologies related to an advanced technology.

Flexible technologies must act in these layers, and are fundamental to automatize all the production processes for:

In‐line/off‐line production monitoring.

The elimination of possible failure conditions.

The decrease of production defects.

The optimization of human resources and of their work.

Business intelligence (BI) and strategic marketing.

The optimization of the warehouse management.

A dynamic production following the real‐time customer requests.

The main flexible technologies are integrated in robotic systems. Robots process information acquired by sensors placed inside and outside the production machines, and generating different outputs suitable for decision making, for the processing coordination, and for the system control.

The flexibility of the information system is mainly in the interconnectivity of all the layers shown in Figure 1.3, representing a standard architecture upgraded by AI and big data system working in the processing layer. Big data systems are characterized by the following features:

Volume (dataset volumes larger than terabytes [1012 byte] and petabytes [1015 byte]).

Velocity (velocity refers to the data generation speed).

Variety (variety of sources with structured, semi structured and unstructured data).

Veracity (quality of the data that is being analyzed, the non‐valuable data are classified as nose or wrong data).

Big data uses the not only SQL (NoSQL) technology. The NoSQL databases (DBs) do not use the relational model, are performed efficiently on clusters, and can be open source.

A primary important aspect concerning the production optimization is the production traceability, performed by sensors. Digital traceability is fundamental in Industry 4.0 scenarios. Automatic detection by gates installed on the production line at each production stage is able to control quality processes and production in general. Table 1.3lists the main sensors used for product traceability.

Radio frequency identification (RFID) systems are constituted by a reader and by a TAG or transponder, enabling the electronic identification of the traced product. The active version is equipped with a lithium (Li) battery or is powered by an external source. The passive RFID is not equipped with a battery and is cheaper offering an infinite lifetime. Besides, the active TAGs are more useful when writing operations. Sensors displaced to control production transmit data using specific protocols. Table 1.4lists some specifications of transmission protocols.

1.1.2 Agent/Firmware Layer: User Interface Layer

The agent layer interconnects the gateway for device communication with all the other components. It is based on the agent's modular architecture suitable for robotic and production machines controlled by sensors. The IoT agent is linked to the IoT controller, and checks the framework environment during the time, by acquiring data by sensors properly programmed by firmware. Firmware is developed through software and hardware interfaces. Integrated development environment (IDE) platforms are usually adopted for firmware development as user interfaces. Agent‐based computing (ABC) tools are able to implement agent functions in modern distributed applications; multi‐agent systems (MASs) are ensembles of agents interacting in the same framework [31]. The MASs support edge and cloud computing, interconnecting innovative applications such as machine learning and blockchain.

1.1.3 Gateway and Enterprise Service Bus Layer

The gateway is an important node executing data routing and switching functions of the information network, using different protocol types. The gateway behaves as a provider, and it is interfaced between the IoT middleware and the agent layer. This layer is responsible for publishing and subscribing the services, message routing, and allows the communication between platforms. The enterprise service bus (ESB) enables service‐oriented architecture (SOA) applications. Typically, the ESB is adopted to collect the digital data sources of different technologies adopted in the same information network, such as big data systems and AI algorithm datasets, by allowing data transfer between different DB systems [32]. ESB solutions are suitable to integrate old technologies with new ones improving the information system and Industry 4.0 implementations. The gateway system covers the role of collector of the packets coming from different sensors applied in the specific production line field. Communication takes place through IEEE 802.11 (WI‐FI/5 GHz) or MODBUS standards, following the most common mechanisms for asynchronous communication including Message Queuing Telemetry Transport (MQTT) protocol [30]. The architecture of the gateway follows Industry 4.0 mechanisms, where the gateway represents the main local component made by:

Читать дальше