The Plan concerning the occurring variations.

The actions to Do and to be controlled.

The Check of the executions by validating expected results.

The Act involving all the activities about the process, the standardization and stability, and improving the existing procedure.

The XmR chart, through the upper and lower control limits, provides the limits of an industrial production process mapping at the same time production results. As a further diagram to adopt for process mapping, a fishbone diagram (Ishikawa diagram) is a cause‐and‐effect approach able to track imperfections, variations, defects, or failures. This diagram is structured as a fish's skeleton with the problem at its head and the causes for the problem following the fish bones. In order to also predict defects or production failures, big data systems facilitate the analysis of the historical data. Big data systems implement NoSQL technology based on the following main categories:

key‐value distributed

document oriented

column oriented

graph oriented

However, some NoSQL DBMSs may have features that belong to more than one of these categories. Some common big data systems are Cassandra, MongoDB, and Hbase.

1.2.5 Technologies of Industry 4.0 and Industry 5.0: Interconnection and Main Limits

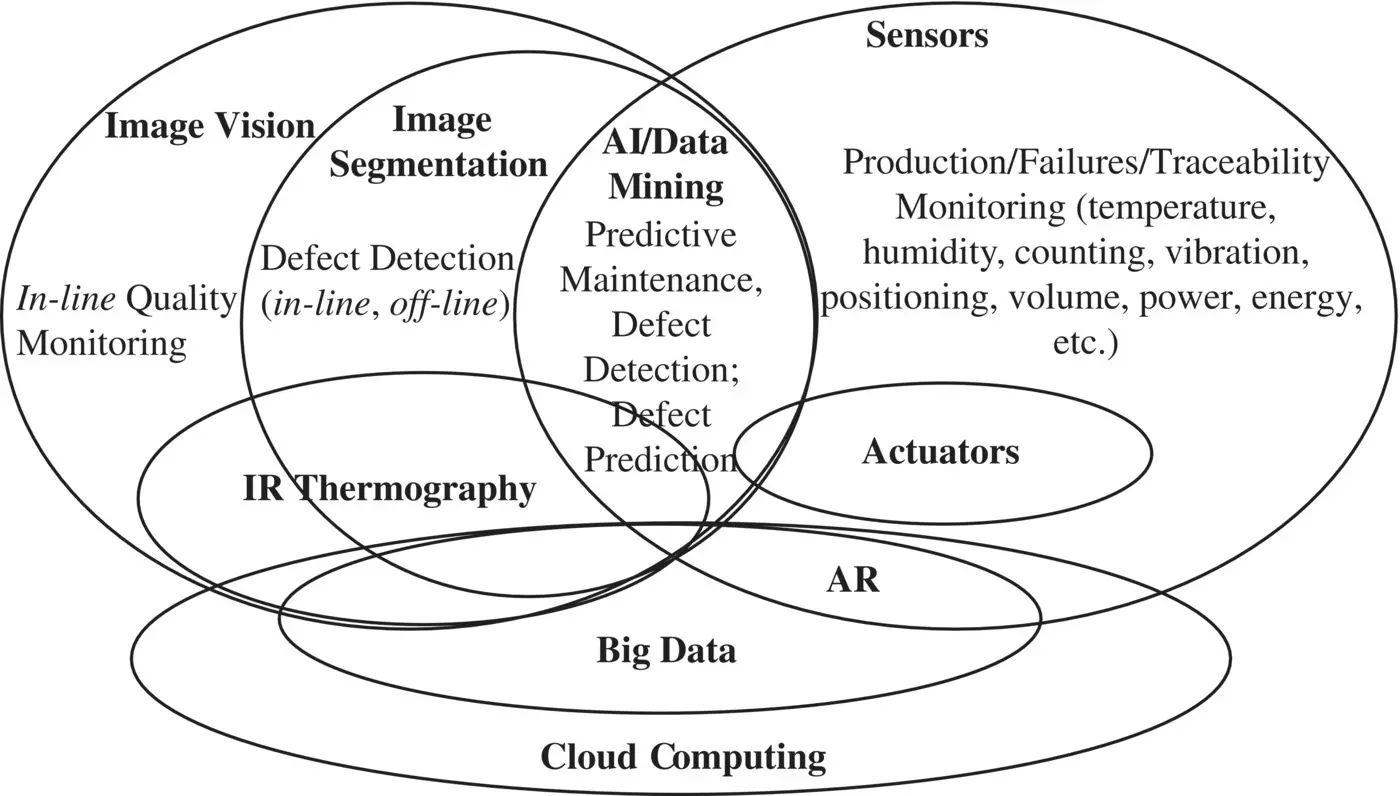

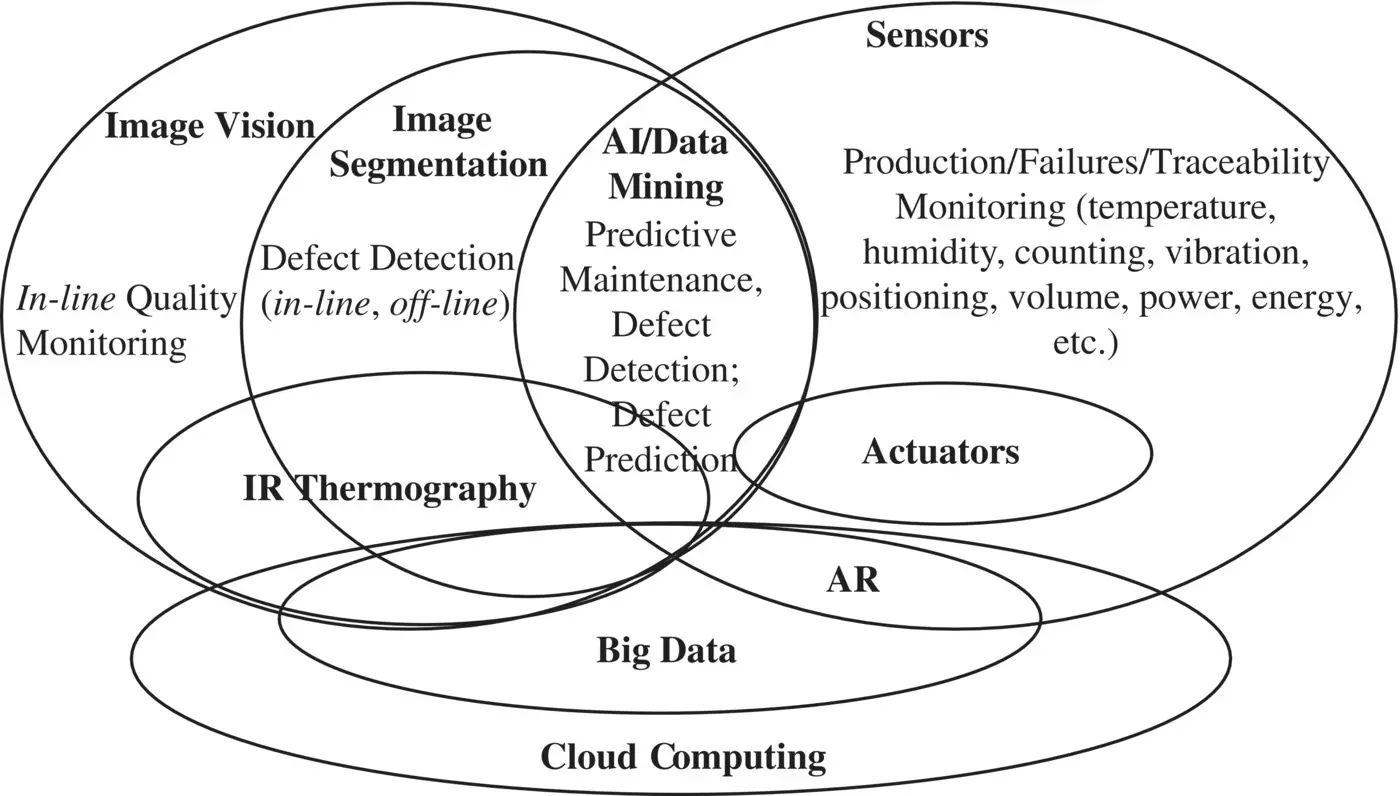

The interoperability of technologies is a fundamental element for the upgrade of the information system and in general for the production. Figure 1.8shows the interoperability of different technologies involved in Industry 4.0 and Industry 5.0 environments. The diagram includes all the main technologies for control and actuation supporting production auto‐adaption managed by the AI engine.

Figure 1.8 Interoperability of different technologies involved in Industry 4.0 and Industry 5.0 environments.

The technologies of Figure 1.8are interconnected in information by exchanging data with different software tools. The components of an innovative information system are divided into two main categories:

Transactional applications: systems and procedures supporting IT and enterprise resource planning (ERP) systems.

Decision support system (DSS): systems and procedures supporting strategic decisions and production processes management by data mining.

The ERP systems are developed for finance, logistics and in general for supply chain management. Subsequently ERP systems evolved into material requirements planning (MRP) tools implementing Business Process Re‐engineering (BPR) logics. The peculiarities of ERP systems are:

integrated solutions

functional modules

information centralization

real‐time availability

fixed functional schemes (standard models)

customer customizations

financial compliance

The implementation phases of ERP systems are summarized by the following steps:

Software selection.

formulation of the business process modeling (BPM).

mapping of existing processes (“AS IS” mapping).

definition of a new implementation scenario concerning future production processes (“TO BE” mapping).

BPR process redesign.

Production gap analysis (detailed list of missing production features).

Formalization of formal documents for the validation of new processes.

System parameterization.

Prototype creation.

Testing of the whole information systems.

The main ERP functions are:

management control

management of purchases and receptions

sales and distribution management

warehouse and logistics management

project management

production, orders, and account processing

human resources management

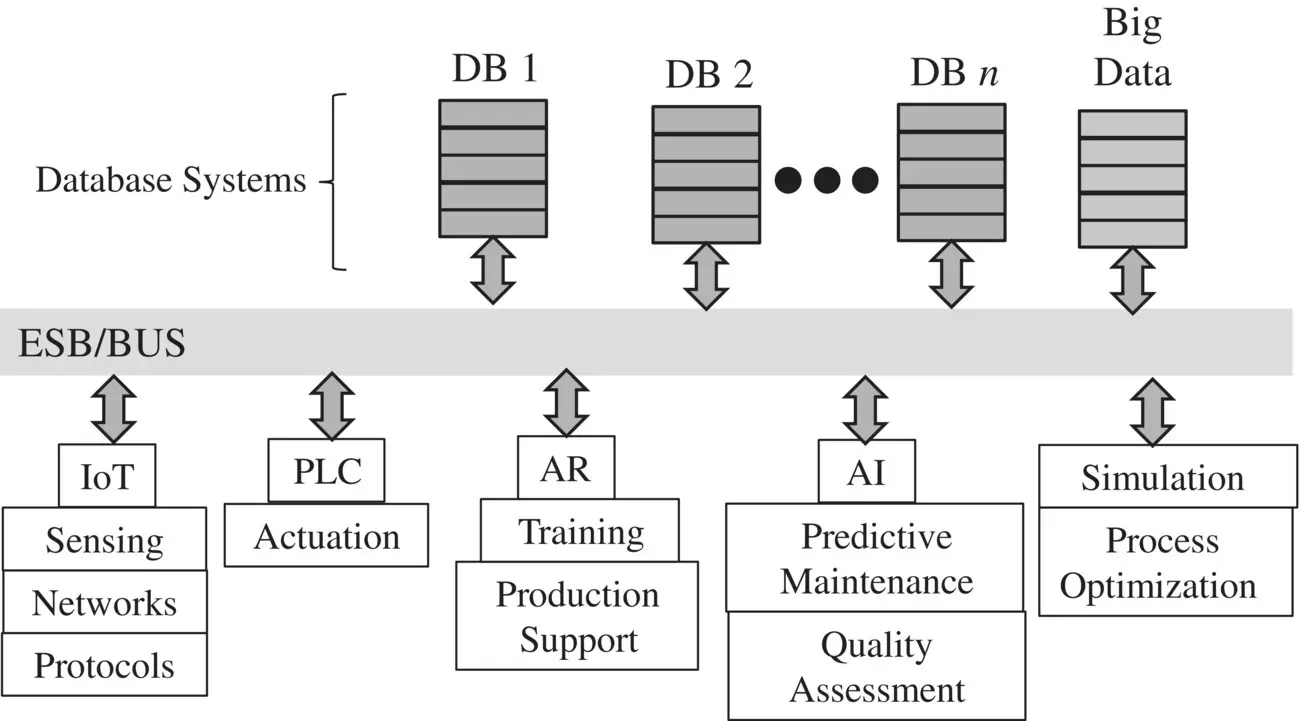

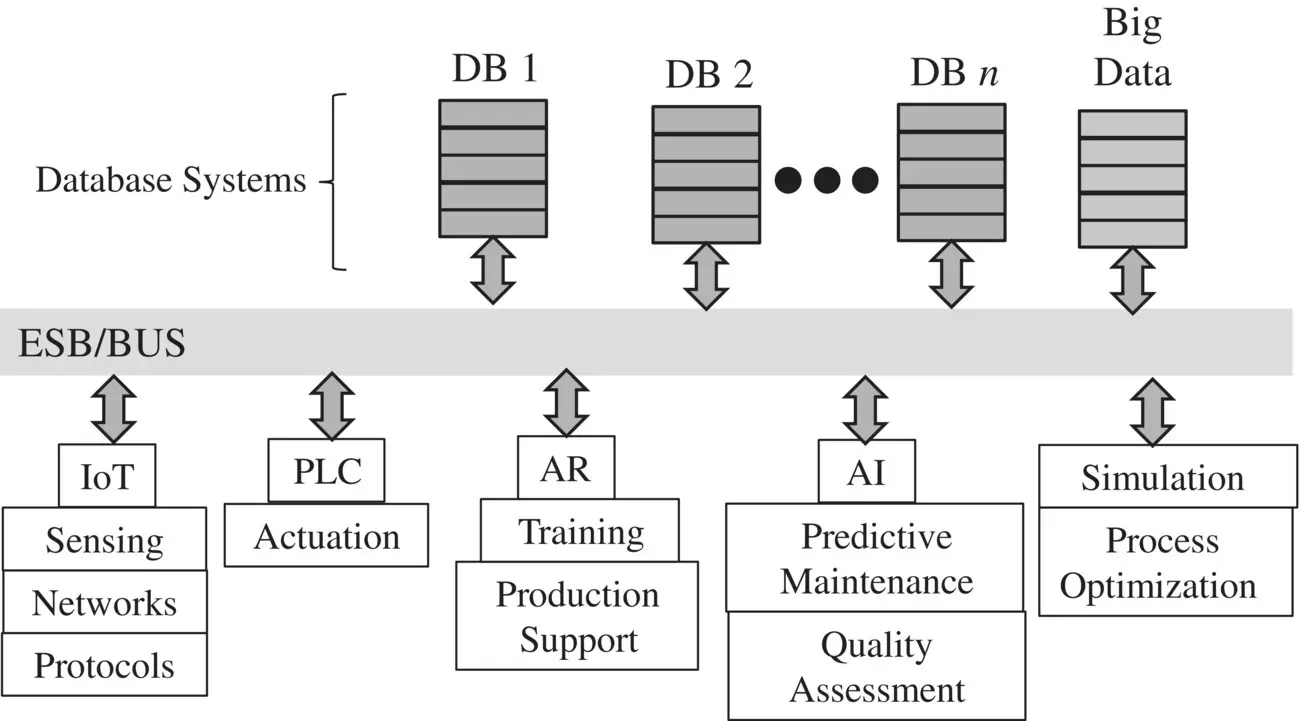

The upgrade of the ERP systems involves AI implementations, thus improving DSS dashboards and decision‐making processes of the whole supply chain. ERP and other software tools must be interconnected in information infrastructure enabling real‐time data processing, sensing, and actuation. According to the architecture of Figure 1.9, information systems interconnect different enabling technologies by means the use of the bus or of the ESB. DBs are synchronized and managed by an advanced ERP having different functions including data migration into the big data system. All the other facilities such as IoT, PLC sensing and actuation, AR and process simulation, are implemented through human–machine interfaces (HMIs) interconnecting the tools with the information system. The information systems are typically managed by a bus or a ESB line.

Figure 1.9 Information system interconnecting enabling technologies.

The bus system is a set of internal connections for the transmission and exchange of signals, supply voltage, and ground potentials. The exchange of signals between the microprocessor and the input and output interfaces therefore takes place via the bus system. The bus lines are classified as:

Address bus: allowing the access of the addresses of the individual boards.

Data bus: reading data from the input cards or data transferred to the board outputs.

Command bus: managing command and control signals within the controller.

Concerning technological limits, the challenge is to improve performance for an innovative Industry 5.0 scenario based on full production automatisms. Table 1.7lists some possible technological limits characterizing innovative technologies to integrate in the company information system.

Table 1.7 Possible limits of advanced technologies and technical risks.

| Technological limits |

Descriptions and mitigations |

| Production time velocity |

Computational cost of sensing and actuation processes must follow the in‐line production timing. Hardware and data computing can introduce relevant delays for real‐time actuation. Cloud data processing or the use of GPUs can be possible solutions |

| AI training dataset |

The training dataset is particularly important in order to define high performance AI models. The training dataset must be constructed with a high quantity of data. In the initial monitoring of the production process, there are few sensor data and the training dataset can provide incorrect outputs. A solution can be the creation of a training dataset based on the creation of artificial data constructed by the initial ones. The dataset must be built with criteria avoiding the creation of redundant data; for example, reproducing in bench test similar data having the features of the production ones |

| Sensor detection and transmission |

The Internet of Things sensor network monitoring production must be designed to detect and to transmit efficiently the signals. The full set of sensors able to monitor a whole production line must be allocated in the precise part of the production line mainly where the production is critical. The sensor sampling frequency is a particularly important parameter to provide enough data to process. In this scenario, a well‐structured local area network, based on the efficient solutions as the optical fiber architecture, typically increases the performance of the data transmission system. Another aspect to improve for data transmission is the correct programming of the time windows synchronizing all sensors |

| Sensor calibration |

The sensor calibration is fundamental for the specific application field and machine to control. The calibration must be performed according to the production layout. A correct sensor calibration provides good data to process. In order to calibrate a production layout correctly, it is useful to simulate before all the signals are involved in the whole production line |

| Noise |

Strong and anomalous vibrations, heat sources, inhomogeneous light conditions, acoustic noises, pollution, and electromagnetic induced fields represent possible causes of incorrect measurements. The noise is decreased by means of electronic boards and amplifiers properly filtering and cleaning the sensor signals |

| Image segmentation techniques |

Image segmentation techniques can be inefficient for the specific defect to detect. AI techniques are adopted as alternative approaches for a further quasi real‐time or post‐processing checking. The processing modality is selected based on the production process to control. If the check is performed at the end of the product processing, the post‐processing modality is adopted, thus avoiding the problem of the computational cost |

| Camera resolution |

Camera resolution can be inadequate for image processing. The optical components to combine with the camera are very important for the detection improvement. Angle of view, field of view, and focal lens are the parameters and elements to verify before the choice and installation of the camera system in the production line. The production layout and the characteristics of the production define the optical requirements of the camera system. A correct design of the camera system also takes into account the pollution of the working environment which in general disturbs the image acquisition |

| IRT |

For an IR thermal camera, as well as the optical parameters, the thermal resolution is also important (a good parameter is <20 mK at +30 °C). Heat sources or reflective surfaces near the detection object increase the measurement signal noise and can saturate the camera chip. The correct positioning and orientation of the thermal camera is important to avoid the problem generated by the reflective surfaces |

| Defect classification |

Defect classification is typically performed by AI algorithms. The training model is structured to detect particular typologies of defects according to product features. The correct formulation of the training dataset plays an import role for correct defect detection and classification. For this purpose, it is necessary to know and pre‐classify defects, thus optimizing the AI training model to apply |

| Traceability |

The traceability can be inaccurate mainly for indoor applications. The choice of the correct technology is a function of the production layout and production processes. Possible correctly positioned gates reading tags avoid the problem associated with the correct indoor positioning |

| Computational cost of smart sensors |

The computational cost in smart hardware technologies must be adapted to the production velocity. For this reason, local data processing can be performed by high performance processors embedded in smart devices, or by GPUs |

| Big data system |

Big data cannot be connected and synchronized with the ERP database systems. A typical condition is to implement a big data system into a database management system |

| Big data analytics |

The analytics tool can fail if there are empty records or wrong data stored in the big data. The definition of criteria to store and filter data in the big data system ensures the correct creation of the dataset to use for AI modeling |

| Actuation |

An incorrect PLC configuration generates a failure in sensing and actuation processing. Preliminary simulations, checks, and tests of the PLC integrated in the whole production line ensures the best actuation according to the specific feedback systems |

| AR |

AR smart glasses can have a low image resolution and low acceleration sensing according to the application. Standard smart glasses integrate an IR thermal camera having a low thermal resolution. The alternative solution is to use a high‐resolution thermal camera wireless interconnected with smartphone cardboard systems avoiding the problem of low thermal resolution |

| Unstructured data |

Many data are not structured and consequently cannot be transferred by the enterprise service bus/bus network or by the wireless system. The association roles, used to extract information from unstructured data, provide more information for the digitized knowledge gain |

| In‐line parameter setting by AI |

The AI engine can fail providing wrong outputs for the real‐time machine parameter calibration and actuation. The AI must be properly checked before its introduction in the production processes |

| Automodification of parameter setting |

The auto‐adaptive system able to change the machine parameter setting can be inaccurate by providing wrong operations and wrong scheduling actions. The automated modification of the parameters can be performed by AI algorithms which must be accurately tested for the specific dataset |

AI, artificial intelligence; AR, augmented reality; GPU, graphics processing unit; IR, infrared; IRT, infrared thermography; PLC, programmable logic controller.

Читать дальше