Ehsan Toyserkani - Metal Additive Manufacturing

Здесь есть возможность читать онлайн «Ehsan Toyserkani - Metal Additive Manufacturing» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

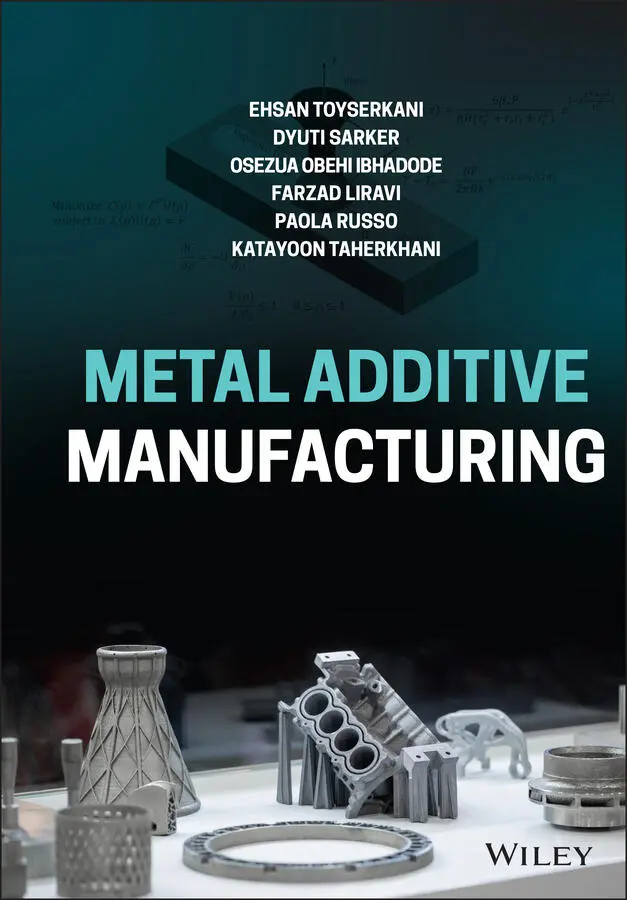

- Название:Metal Additive Manufacturing

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 100

- 1

- 2

- 3

- 4

- 5

Metal Additive Manufacturing: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Metal Additive Manufacturing»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

A comprehensive review of additive manufacturing processes for metallic structures Metal Additive Manufacturing

Metal Additive Manufacturing

Metal Additive Manufacturing — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Metal Additive Manufacturing», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

Table of Contents

1 Cover

2 Title Page

3 Copyright Page

4 Dedication Page

5 Preface

6 Abbreviations Nomenclature Greek Symbols

7 1 Additive Manufacturing Process Classification, Applications, Trends, Opportunities, and Challenges 1.1 Additive Manufacturing: A Long‐Term Game Changer 1.2 AM Standard Definition and Classification 1.3 Why Metal Additive Manufacturing? 1.4 Market Size: Current and Future Estimation 1.5 Applications of Metal AM 1.6 Economic/Environmental Benefits and Societal Impact 1.7 AM Trends, Challenges, and Opportunities 1.8 Looking Ahead References

8 2 Basics of Metal Additive Manufacturing 2.1 Introduction 2.2 Main Metal Additive Manufacturing Processes 2.3 Main Process Parameters for Metal DED, PBF, and BJ 2.4 Materials References

9 3 Main Sub‐Systems for Metal AM Machines 3.1 Introduction 3.2 System Setup of AM Machines 3.3 Laser Basics: Important Parameters Needed to be Known for AM 3.4 Electron Beam Basics 3.5 Powder Feeders and Delivery Nozzles Technology 3.6 CAD File Formats 3.7 Summary References

10 4 Directed Energy Deposition (DED) 4.1 Introduction 4.2 Laser Material Interaction and the Associated Significant Parameters to Laser AM 4.3 E‐beam Material Interaction 4.4 Power Density and Interaction Time for Various Heat Source‐based Material Processing 4.5 Physical Phenomena and Governing Equations During DED 1 4.6 Modeling of DED 4.7 Case Studies on Common Modeling Platforms for DED 4.8 Summary References

11 5 Powder Bed Fusion Processes 5.1 Introduction and Notes to Readers 5.2 Physics of Laser Powder bed Fusion (LPBF) 5.3 Physics and Modeling of Electron Beam Additive Manufacturing References

12 6 Binder Jetting and Material Jetting 6.1 Introduction 6.2 Physics and Governing Equations 6.3 Numerical Modeling 6.4 Summary References

13 7 Material Extrusion 7.1 Introduction 7.2 Analytical Modeling of ME 7.3 Numerical Modeling of ME 7.4 Summary References

14 8 Material Design and Considerations for Metal Additive Manufacturing 8.1 Historical Background on Materials 8.2 Materials Science: Structure–Property Relationship 8.3 Manufacturing of Metallic Materials 8.4 Solidification of Metals: Equilibrium 8.5 Solidification in Additive Manufacturing: Non‐Equilibrium 8.6 Equilibrium Solidification: Theory and Mechanism 8.7 Non‐Equilibrium Solidification: Theory and Mechanism 8.8 Solute Redistribution and Microsegregation 8.9 Constitutional Supercooling 8.10 Nucleation and Growth Kinetics 8.11 Solidification Microstructure in Pure Metals and Alloys 8.12 Directional Solidification in AM 8.13 Factors Affecting Solidification in AM 8.14 Solidification Defects 8.15 Post Solidification Phase Transformation 8.16 Phases after Post‐Process Heat Treatment 8.17 Mechanical Properties 8.18 Summary References

15 9 Additive Manufacturing of Metal Matrix Composites 9.1 Introduction 9.2 Conventional Manufacturing Techniques for Metal Matrix Composites (MMCs) 9.3 Additive Manufacturing of Metal Matrix Composites (MMCs) 9.4 AM Challenges and Opportunities 9.5 Preparation of Composite Materials: Mechanical Mixing 9.6 Different Categories of MMCs 9.7 Additive Manufacturing of Ferrous Matrix Composites 9.8 Additive Manufacturing of Titanium‐Matrix Composites (TMCs) 9.9 Additive Manufacturing of Aluminum Matrix Composites 9.10 Additive Manufacturing of Nickel Matrix Composites 9.11 Factors Affecting Composite Property 9.12 Summary References

16 10 Design for Metal Additive Manufacturing 10.1 Design Frameworks for Additive Manufacturing 10.2 Design Rules and Guidelines 10.3 Topology Optimization for Additive Manufacturing 10.4 Lattice Structure Design 10.5 Design for Support Structures 10.6 Design Case Studies 10.7 Summary References

17 11 Monitoring and Quality Assurance for Metal Additive Manufacturing 11.1 Why are Closed‐Loop and Quality Assurance Platforms Essential?[1] 1 11.2 In-Situ Sensing Devices and Setups 11.3 Commercially Available Sensors 11.4 Signal/Data Conditioning, Methodologies, and Classic Controllers for Monitoring, Control, and Quality Assurance in Metal AM Processes 11.5 Machine Learning for Data Analytics and Quality Assurance in Metal AM 11.6 Case Study 11.7 Summary References

18 12 Safety 12.1 Introduction 12.2 Overview of Hazards 12.3 AM Process Hazards 12.4 Laser Safety in Additive Manufacturing 1 12.5 Electron Beam Safety 12.6 Powder Hazards 12.7 Human Health Hazards 12.8 Comprehensive Steps to AM Safety Management 12.9 Summary References

19 Index

20 End User License Agreement

List of Tables

1 Chapter 2 Table 2.1 Configurations of major commercially available PBF systems. Table 2.2 The market cost of wire and AM grade powder per pound for some of ... Table 2.3 Configurations of commercially available DED systems. Table 2.4 Configurations of commercially available BJ systems. Table 2.5 Influence of increasing process parameters on dimensions of a sing...

2 Chapter 3Table 3.1 Comparison between AM processes adapted from [16] with several cha...Table 3.2 Comparisons of some representative AM processes.

3 Chapter 4Table 4.1 Optical properties and Brewster angle of several materials for 106...Table 4.2 Reflectivity of different surface roughness for a 10.6‐μm waveleng...

4 Chapter 5Table 5.1 Material input parameters for LPBF [2, 3].Table 5.2 Equations used for powder particles shape characterization [18].Table 5.3 Parameters for the single‐layer multiple‐track scanning.Table 5.4 Melt pool depths in the multi‐track scanning.

5 Chapter 8Table 8.1 Phase formation during solidification of different types of AM ste...Table 8.2 Phase formation during solidification of different types of AM Al ...Table 8.3 Chemical composition of different superalloys.Table 8.4 Post solidification phases of In625.Table 8.5 Post solidification phases of IN718.Table 8.6 Different types of Stellite.Table 8.7 Post solidification phases of Stellite.Table 8.8 Post solidification phases of Ti alloys.Table 8.9 The estimated cooling rates necessary to obtain various morphologi...

6 Chapter 9Table 9.1 Summary of microstructures formed in TMCs.Table 9.2 Mechanical and wear property of CP‐Ti and different kinds of TMCs ...

7 Chapter 10 Table 10.1 Metal additive technologies compared with key design consideratio...Table 10.2 Topology optimization of point loaded structures.Table 10.3 Objectives and constraints for topology optimization of arbor pre...Table 10.4 Arbor press components and mass composition.Table 10.5 Design space and optimized result of arbor press components.Table 10.6 Design iterations for framework.

8 Chapter 11Table 11.1 Co‐axial mounted based sensors used in LPBF and LDED.Table 11.2 Off‐axial mounted based sensors used in LPBF and LDED.Table 11.3 Some commercial sensors mounted on the LPBF machines.Table 11.4 Some commercial sensors mounted on LDED machines.Table 11.5 Calibration of RGB values with temperature. For colorful spectrum...Table 11.6 Machine learning methods used in LPBF and LDED.Table 11.7 Performance of different SOM dimensions based on the SOEDNN.Table 11.8 Types and print parameters in print 1.Table 11.9 Types and print parameters in print 2.Table 11.10 Applying the detection algorithms on the five consecutive layers...Table 11.11 The range of p ‐value from ANOVA single‐factor analysis of the var...Table 11.12 The percentage of identification for each size of the defect and...Table 11.13 Confusion matrix to compare the prediction of the algorithm (AL)...Table 11.14 Evaluation metrics of AL algorithm based on the CT scan result f...Table 11.15 Evaluation metrics of AL algorithm based on the CT scan result f...

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Metal Additive Manufacturing»

Представляем Вашему вниманию похожие книги на «Metal Additive Manufacturing» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Metal Additive Manufacturing» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.