Ehsan Toyserkani - Metal Additive Manufacturing

Здесь есть возможность читать онлайн «Ehsan Toyserkani - Metal Additive Manufacturing» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Metal Additive Manufacturing

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 100

- 1

- 2

- 3

- 4

- 5

Metal Additive Manufacturing: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Metal Additive Manufacturing»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

A comprehensive review of additive manufacturing processes for metallic structures Metal Additive Manufacturing

Metal Additive Manufacturing

Metal Additive Manufacturing — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Metal Additive Manufacturing», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

Greek Symbols

αThermal diffusivityαtCoefficient of thermal expansionβAbsorption factorβAbsorption factorβpPowder particles’ absorbed coefficientβwSubstrate laser power absorptivityγSurface tensionγNet electron beam energy ( Chapter 5)γESpecific surface energyγSLSolid–liquid interfacial free energyγSVSolid–vapor interfacial energyγLVLiquid–vapor interfacial energy  Shear rateΓTorque of electrical motors in FDMΓSurface function ( Chapter 10)δSolid/liquid interface thicknessδDirac delta function ( Chapter 6) εTotal strainεcCooling rateεtEmissivityεMMechanical strainsεTThermal strainsεpEquivalent plastic stressεVacuum permittivity ε mMechanical strain ε thThermal strain∑Covariance matrixηDynamic viscosityηPowder catchment efficiency (wherever it refers to throughout chapters)ηNumerical damping coefficient for OCM ( Chapter 10)ηLearning rate ( Chapter 11)ηeAbsorption efficiency for electron beamηdDynamic viscosityηpPowder catchment efficiencyθRepresenting different angles based on figuresθWetting angle ( Chapter 2)θFar‐field divergence angle ( Chapter 3)θDimensionless temperature in numerical models ( Chapter 7)θjetAngle between powder jet and substrateθdDynamic wetting angleθeqSteady‐state angleΘDimensionless temp in analytical modelsλWavelengthλLagrange multiplier ( Chapter 10)λnRoots of zero‐order Bessel function of its first kindμViscosityμMembership function ( Chapter 11)υFrequency ( Chapter 3)υKinematic viscosityρDensityρbDensity of binderρpbPowder bed densityρcDensity of melted powder alloyρsDensity of substrate materialρsPacking density of the pores ( Chapter 6)σStefan–Boltzmann constantσCovariance ( Chapter 11)σcCharge densityσijElastic stressτThermal time constantτcDimensionless capillary timeϕDifferent label for angles as indicated in the associated figures ϕPowder bed porosityϕShape factorΦInterpolation function ( Chapter 10)ϕ(x, y)Level‐set equationϕtapTapped porosityϕ(t)Rate of heat liberation in a continuous point sourceØAngle of incidenceΨStrain energyωSpinning speedωRelaxation factor ( Chapter 11)ωiStrength of anisotropyωrAngular velocity of the actuating motorΩSubstrate surfaces or melt pool boundary and material domain

Shear rateΓTorque of electrical motors in FDMΓSurface function ( Chapter 10)δSolid/liquid interface thicknessδDirac delta function ( Chapter 6) εTotal strainεcCooling rateεtEmissivityεMMechanical strainsεTThermal strainsεpEquivalent plastic stressεVacuum permittivity ε mMechanical strain ε thThermal strain∑Covariance matrixηDynamic viscosityηPowder catchment efficiency (wherever it refers to throughout chapters)ηNumerical damping coefficient for OCM ( Chapter 10)ηLearning rate ( Chapter 11)ηeAbsorption efficiency for electron beamηdDynamic viscosityηpPowder catchment efficiencyθRepresenting different angles based on figuresθWetting angle ( Chapter 2)θFar‐field divergence angle ( Chapter 3)θDimensionless temperature in numerical models ( Chapter 7)θjetAngle between powder jet and substrateθdDynamic wetting angleθeqSteady‐state angleΘDimensionless temp in analytical modelsλWavelengthλLagrange multiplier ( Chapter 10)λnRoots of zero‐order Bessel function of its first kindμViscosityμMembership function ( Chapter 11)υFrequency ( Chapter 3)υKinematic viscosityρDensityρbDensity of binderρpbPowder bed densityρcDensity of melted powder alloyρsDensity of substrate materialρsPacking density of the pores ( Chapter 6)σStefan–Boltzmann constantσCovariance ( Chapter 11)σcCharge densityσijElastic stressτThermal time constantτcDimensionless capillary timeϕDifferent label for angles as indicated in the associated figures ϕPowder bed porosityϕShape factorΦInterpolation function ( Chapter 10)ϕ(x, y)Level‐set equationϕtapTapped porosityϕ(t)Rate of heat liberation in a continuous point sourceØAngle of incidenceΨStrain energyωSpinning speedωRelaxation factor ( Chapter 11)ωiStrength of anisotropyωrAngular velocity of the actuating motorΩSubstrate surfaces or melt pool boundary and material domain

1 Additive Manufacturing Process Classification, Applications, Trends, Opportunities, and Challenges

Learning Objectives

At the end of this chapter, you will be able to:

Understand the standard definition of additive manufacturing (AM) and seven standard classes of AM processes

Gain basic knowledge on AM market size

Gain basic knowledge of opportunities, threats, and trends in the AM industry

Gain insight into applications of metal AM

1.1 Additive Manufacturing: A Long‐Term Game Changer

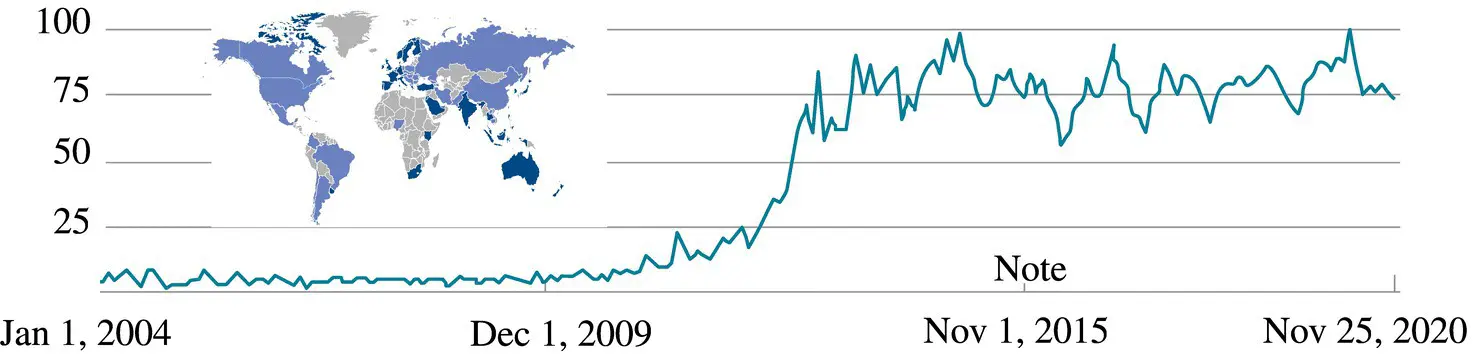

Additive manufacturing (AM), also known as 3D printing, is a layer‐by‐layer fabrication technology “poised to be one of the most valued forms of manufacturing in history” [1]. AM is becoming a major research target for industrialized countries as they seek to regain leadership in manufacturing through innovation. The global economy is on the verge of the next industrial revolution, known as “Industry 4.0”, i.e. the fourth industrial revolution. Sector after sector is pulling away from traditional/conventional methods of production in order to engage in and utilize AM. This fresh manufacturing method has garnered a great deal of public curiosity and international publicity. Every week brings news of novel and astounding AM innovations. This technology, which builds up objects by layers, has piqued the industrialized world's curiosity and imagination. This public interest was triggered around 2013–2014, as shown in Figure 1.1, in which the Google Trend suggests that a public interest in “3D Printing” has been increased more than 50‐fold from 2012 to 2016. The trend stays very much the same from 2017 to 2020, but it is the highest in Google Trend compared with counterpart advanced manufacturing technologies. This figure also sheds some light on the geographical distribution of the public interest. North America, Europe, and Australia are among the regions with the highest number of news and interests related to “3D printing” technologies.

Figure 1.1 Global public interest trends for “3D Printing”.

Source: Extracted from “Google Trends” on 25 November 2020.

In November 2015, the United Nations encouraged countries to invest in AM technology, forecasting major expansions in business and explosive economic growth and comparing 3D printing to the most influential technologies of the past, such as airplanes, antibiotics, and semiconductors [2]. AM technology has been recommended for substantial research investment [3]. Major initiatives have been announced in Singapore, Australia, the United States, Canada, and Europe [4]. McKinsey estimates that by 2030, the global economic impact approaches $550 billion per year [5].

As worldwide interest in AM escalates, numerous industries are taking steps to integrate AM technologies into their applications and offerings. Many industries, including aerospace, medical, automotive, tooling, energy, natural resources, consumer, defense, etc. have started to embrace the benefits of AM processes.

For years, AM has been identified as a technology addressing “economies of scope” through customization, prototyping, and low‐volume manufacturing. However, in recent years, AM has been deployed for “economies of scale,” i.e. mass production, without compromising the economies of scope. This advancement from prototyping to serial production has created many research and development opportunities, especially for quality management and certification. Richard D'Aveni writes: Today, additive manufacturing is achieving economies of scale in a variety of ways– and doing so without sacrificing economies of scope … No longer limited to product prototypes, customized one‐offs, or specialized items made in small quantities, AM is now beginning to take over the kinds of mass manufacturing that have long dominated the industrial economy [6].

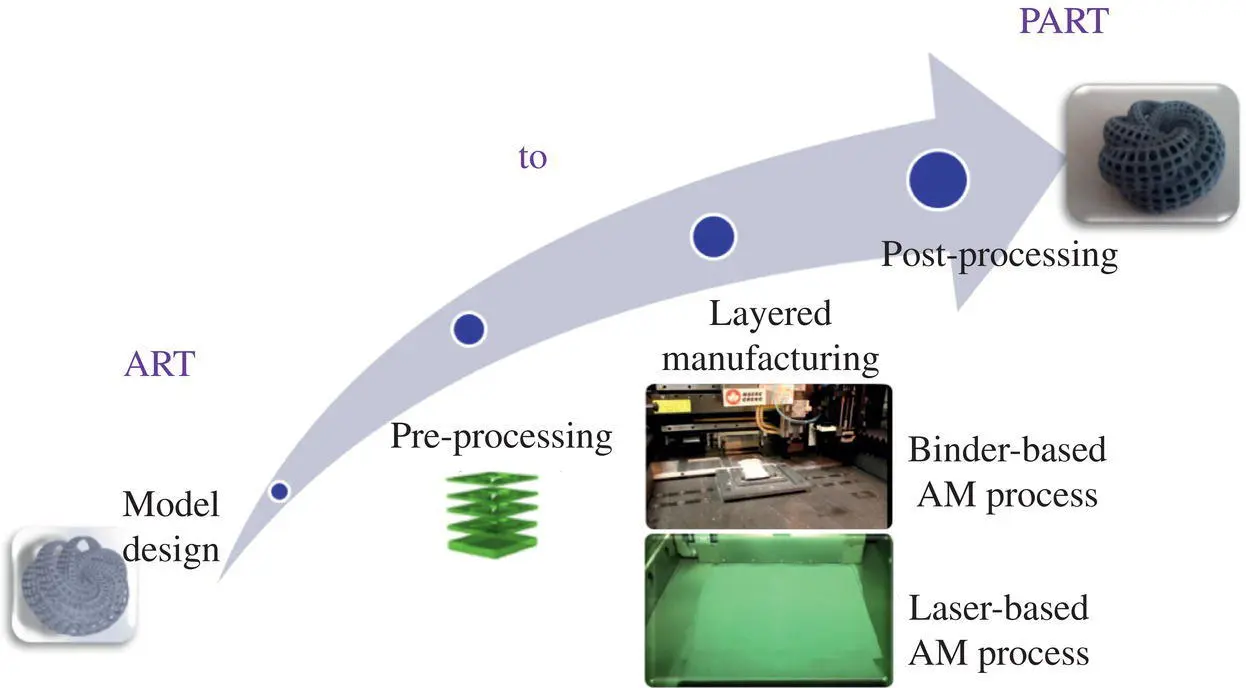

AM has been considered a platform to convert digital models to physical parts in a short chain of processes, a platform facilitating a rapid move from “Art” to “Part” in a fancy analogy. The process starts with a digital model that reflects the desired design. Preprocessing is needed on the file depending on materials, applications, and AM processes. A proper AM process must be chosen that fulfills the material and application of interest. After the layered manufacturing is completed, post‐processing may be needed to arrive at the physical part eventually. Figure 1.2shows the AM process chain schematically.

Figure 1.2 AM chain, enabling physical parts from digital design.

The history of AM is very well connected to human civilization. The idea of “layered manufacturing” has been around as the activities of human kind have been recorded. More than five million blocks of limestone were put together “stone‐by‐stone” by ancient Egyptians to build the pyramids using human‐made stones. Layered cakes were formally introduced in Maria Parloa's Appledore Cook Book, published in Boston in 1872, which contained one of the first layer‐by‐layer made cake recipes. Francois Willeme developed a method called “photographic sculpture” in 1859. In this method, 3D models of human subjects could be extracted using 24 cameras placed at different angles. Joseph E. Blanther patented an apparatus in 1892, where the apparatus uses a layering idea to create 3D topographical maps. The film industry also fancied the idea of AM processes through science fiction that speculated on “replicating” technology. The term “replicator” was used in the series “Star Trek: The Next Generation.” In the animated series in 1974 and in the episode entitled “The Practical Joker”!, there were scenes where food could be requested to be replicated.

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Metal Additive Manufacturing»

Представляем Вашему вниманию похожие книги на «Metal Additive Manufacturing» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Metal Additive Manufacturing» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.