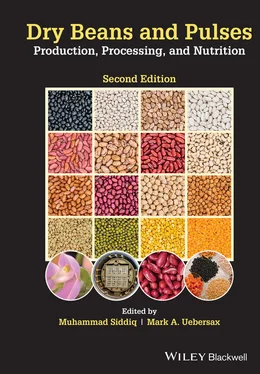

Dry Beans and Pulses Production, Processing, and Nutrition

Здесь есть возможность читать онлайн «Dry Beans and Pulses Production, Processing, and Nutrition» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Dry Beans and Pulses Production, Processing, and Nutrition

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 100

- 1

- 2

- 3

- 4

- 5

Dry Beans and Pulses Production, Processing, and Nutrition: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Dry Beans and Pulses Production, Processing, and Nutrition»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

The second edition of the most complete and authoritative reference on dry beans production, processing, and nutrition available Dry Beans and Pulses: Production, Processing, and Nutrition

Dry Beans and Pulses: Production, Processing, and Nutrition, Second Edition

Dry Beans and Pulses Production, Processing, and Nutrition — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Dry Beans and Pulses Production, Processing, and Nutrition», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

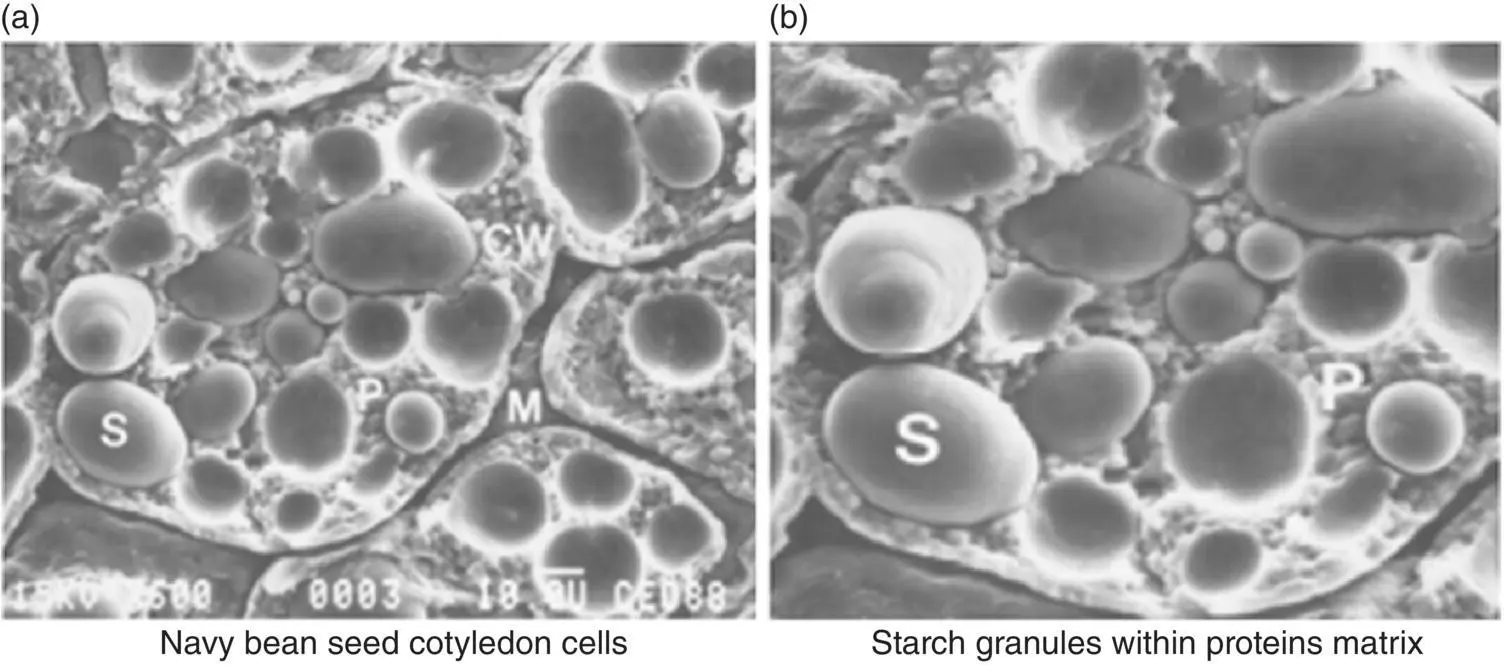

Relatively small spherical protein bodies (approximately 5 μm) form a matrix that supports embedded starch granules of varied size and oblong shapes (Uebersax et al. 1989), as shown in Figure 3.6a , with an expanded view of this matrix presented in Figure 3.6b . Zimmermann et al. (1967) demonstrated partitioning of nutrients within the cotyledons with greater levels of protein and trypsin inhibitor present in the outer layers compared to the inner layers of the tissue.

Processed texture and nutrient availability of beans are influenced by the dimensions and arrangement of the cotyledonary cells. The outermost cells are an epidermal layer with an inner and outer portion. The innermost cells are elongated, and the outer layer cells are cubical. The next layer is the hypodermis, which has larger elliptically shaped cells. Both the epidermal and hypodermis layers appear granular, which is characteristic of protein.

The remaining and largest portion of the cotyledon parenchyma cells are bound by a distinct cell wall and middle lamella with a few vascular bundles. The parenchyma cells have thick walls that give rigidity to the cotyledon. Within each parenchyma cell, starch granules are imbedded within a protein matrix. The secondary walls found only in mature parenchyma cells are very thick and contain pits that facilitate the diffusion of water during soaking. The middle lamella is composed mainly of pectic substances that serve to hold cells together while giving rigidity and strength to the total tissue. Pectic substances (complex polygalacturonic acid residues that possess various degrees of methyl side groups) actively cross‐link with divalent cations to form cohesive structures that significantly affect the texture of the plant tissues (Gooneratne et al. 1994; Njoroge et al. 2015). This commonly observed mechanism in beans is discussed in Chapter 5.

Lee et al. (1983) produced fractionated navy beans with a 90% cotyledon yield, which was further milled and air classified to yield a fine protein component (32% w/w; containing > 40% protein and 31% starch) and a coarse starch fraction (55% w/w; containing > 67% starch and 16% protein). These results were indicative of the general distribution of protein and starch within the cotyledon portion of the beans.

Fig. 3.6. SEMs showing structural components of dry navy bean: (a) seed cotyledon cells and (b) Starch granules embedded with a protein matrix ( CW = cell wall, M = middle lamella, P = protein bodies, S = starch granules, P = protein ).

Source: Original images by author, M.A. Uebersax.

Embryo

The embryo is a relatively small portion of the seed mass (typically < 2%) but has a dramatic influence on seed quality. This biologically active component of mature seeds possesses high levels of enzymatic activity that are readily activated by optimum moisture and temperature conditions. The mobilization and oxidization of lipids high in unsaturated fatty acids produce highly oxidized off‐flavors. High temperatures (> 130°F) that may occur during even mildly adverse storage conditions will result in embryo damage with irreversible loss of seed vitality. It is commonly recognized that precursors of the germination process are initiated during ambient water‐soaking conditions. Thus, traditional overnight cold‐water soaking of beans activates many complex embryonic catabolic enzymes associated with seed spouting (e.g., proteases, amylases, pectinases, cellulases and phytases) and, therefore, enhances the water‐hydrating and water‐holding capacity of the bean.

CHARACTERISTICS OF SEED SIZE AND SHAPE

Commercial classes of dry beans are diverse and distinguished by seed size and shape, and seed coat color. The physical characteristics of dry beans are presented in Table 3.1 . Seed size is expressed in various formats, depending on convention and practice. These include: (1) grams per hundred seeds, (2) seed counts per 100 grams, (3) seeds per pound, and (4) standard US sieve size characterization.

Expressing seed size as weight per unit is common among plant breeders and seed specialists; desired seed size is defined by the commercial market class. Thus, grams per 100 seed count will vary from 48–56 g/100 seed for the large‐seeded kidney bean to 15–16 g/100 seed for the small white classes. Navy bean seeds weighing 17–19 g/100 seeds are common. Alternatively, black beans are generally selected to a size of about 500–550 seeds/100 g.

Expressing seed size as the number of seeds per pound is common within the agricultural sector of the dry bean industry and is typically used to establish seed planting rates required for desired plant densities (plant population per acre). The approximate number of seeds per pound for specific dry bean market classes is provided in Table 3.2 .

Table 3.2. Seed size of selected commercial market classes of dry beans (expressed as seed count per pound).

Source: Smoliak et al. (1990), Kandel and Endre (2019).

| Commercial market class | Seeds/Pound |

|---|---|

| Black | 2,100–2,500 |

| Cranberry | 900–1,000 |

| White kidney | 825–1,280 |

| Great northern | 1,300–1,600 |

| Light/dark red kidney | 800–1,000 |

| Navy | 2,200–2,400 |

| Pink | 1,300–1,600 |

| Pinto | 1,200–1,600 |

| Small red | 1,300–2,000 |

| Yellow | 1,000–1750 |

Seed size is influenced by growing conditions, seed maturity, and position within the plant canopy and the individual pod. Variation in seed size has been demonstrated under differential abiotic conditions (low moisture and high temperatures). Exceptionally small seed size diminishes processing performance (e.g., decreased hydration capacity and minimal swelling). Therefore, seeds are commercially screened to remove smaller seed and to increase the homogeneity of the lot. Selectively screening by size increases the hydration yield performance of a bean lot and enhances the consistency of the finished product.

US standard sieves are used to screen beans for grade standard specifications. The United States Department of Agriculture (USDA) standards for dry beans (USDA 2017a) state that “well‐screened” beans “shall mean that the beans are uniform in size and are practically free from such small, shrivelled, underdeveloped beans, splits, broken beans, large beans, and foreign material that can be removed readily…through use of sieves.” Sieves are to be constructed of 0.319‐inch‐thick metal with perforated round holes. Sizes are specified as a 30/64 sieve (0.4687 inch on a 11/64‐inch center); a 28/64 sieve (0.4375 inch on 19/32‐inch center); and a 24/64 sieve (0.0319 inch on a 17/32‐inch center). All rows of perforations are to be staggered. The screening is conducted in commercial operations (see Chapter 4), and these sieve specifications are used during USDA grading procedures to the assess sample uniformity for size.

Commercial market classes have characteristic seed shapes that range from spherical to elongated (e.g., navy beans are generally characterized by a small round seed whereas kidney beans have elongated seed that resemble the human kidney). Similar to seed size, seed shape is under genetic control; however, deviations may occur due to stressed growing conditions (i.e., water availability and temperature profiles throughout the growing season).

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Dry Beans and Pulses Production, Processing, and Nutrition»

Представляем Вашему вниманию похожие книги на «Dry Beans and Pulses Production, Processing, and Nutrition» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Dry Beans and Pulses Production, Processing, and Nutrition» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.