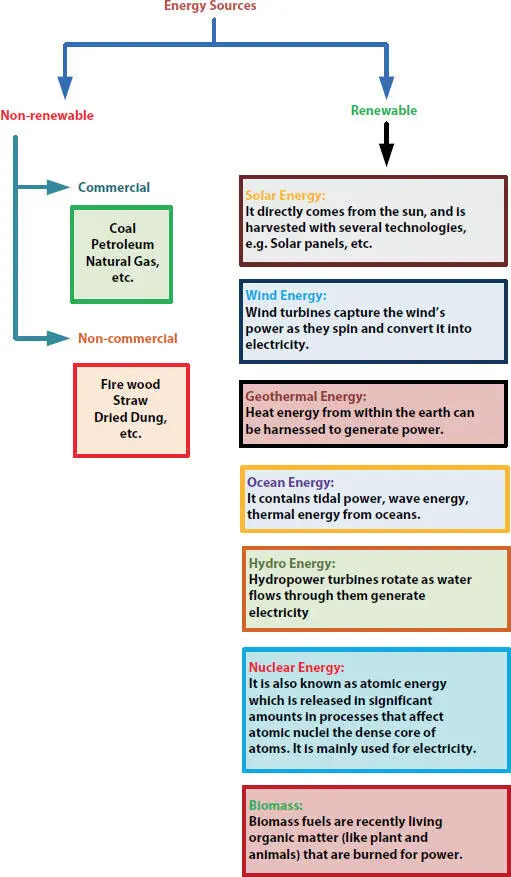

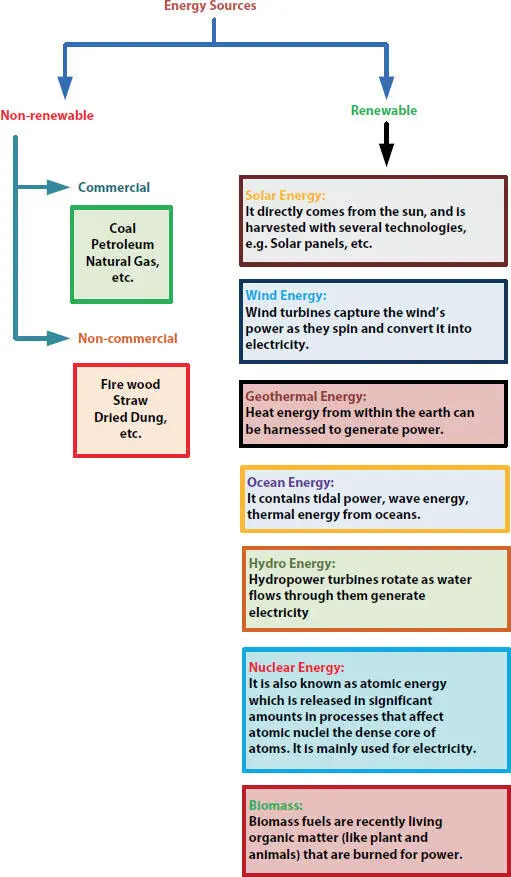

The fuels obtained from conventional sources of energy are costly in nature and also influence the global economy. To overcome all these kinds of concerns and keeping an important point of view in mind for the future, there is a great need to focus on research related to renewable sources energy for producing clean and environmental friendly fuels. The possible pathways to obtain fuels from conventional and renewable sources of energy are presented in Figure 1.2.

Figure 1.2 Distribution of sources of energy.

1.2 Renewable Energy Sources: The Great Hope of the Future

To reduce the harmful effects created by the exploitation of conventional sources of energy, there are two prime ways [2]:

1 (i) Find an alternate way to catch the carbon dioxide and release after treatment (generated by fossil fuel consumption) or do not let release carbon dioxide directly into the atmosphere.

2 (ii) To search for other alternative fuels which do not release carbon dioxide gas.

Among the available sources of renewable energy, solar energy and biomass are attaining great attention by researchers worldwide because the combination of solar energy and biomass provides a great platform to pursue a significant research for producing clean and pure renewable fuel.

In solar energy, photons are used to provide heat (low temperature) instead of thermal energy to carry out a chemical reaction and this process is known as photocatalysis (a subcategory of catalysis). There are basically three big advantages of photocatalysis valorization such as purification of air or water, production of clean fuel from renewable sources, and generation of quality chemicals. It is a well-known fact that the less quantity of absolutely freely available solar radiation on the surface is utilizing.

Still, many industries are dependent on the use of conventional fuels due to lack of research in the field of green chemistry in terms of photocatalysis. Plants manufacture their food due to photochemical reactions which is initiated by sunlight and considered as only renewable source for production of food for human beings and animals, conversion of energy into useful ways, and production of various chemicals. This book chapter discusses in brief about types of biomass and their conversion technologies for obtaining valuable chemicals due to photocatalytic valorization.

1.2.1 Biomass Types and Their Composition

Biomass can be obtained from nature directly in the form of waste. According to many varieties, biomass can be divided into several categories which are given below [3]:

1 (a) Biomass from wood (Stems, branches, sawdust, etc.)

2 (b) Herbaceous biomass (Flowers, grasses, straws, corncob, rice husk, etc.)

3 (c) Aquatic biomass (Marine and freshwater algae, microalgae, etc.)

4 (d) Animal and human waste biomass (Bones, various other manures, etc.)

5 (e) Contaminated biomass and industrial biomass wastes (semi-biomass: Municipal solid wastes, fiberboard, plywood, etc.)

6 (f) Biomass mixture.

Feedstocks of biomass are divided into several analyses such as proximate, ultimate, and structural. The compositional values of various biomass types are given in Table 1.1according to chemical/elemental analysis.

Table 1.1 Elemental and chemical composition of biomass types [4].

| Biomass groups/elemental composition |

Wood biomass |

Herbaceous biomass |

Aquatic biomass |

Animal and human waste biomass |

Contaminated biomass and industrial biomass wastes |

Biomass mixture |

| C (%) |

49–57 |

42–58 |

27–43 |

57–61 |

43–45 |

45–71 |

| O (%) |

32–45 |

34–49 |

34–46 |

21–25 |

36–41 |

16–46 |

| H (%) |

5–10 |

3–9 |

4–6 |

7–8 |

5–6 |

6–11 |

| S (%) |

<1–1 |

<1–1 |

1–3 |

1–2 |

0.25–0.4 |

<1–2 |

| N (%) |

<1–1 |

<1–3 |

1–3 |

6–12 |

1.5–1.75 |

1–6 |

| VM (%) |

30–80 |

41–77 |

42–53 |

43–62 |

76–77.5 |

41–79 |

| FC (%) |

6–25 |

9–35 |

22–33 |

12–13 |

11–16 |

1–15 |

| M (%) |

5–63 |

4–48 |

8–14 |

3–9 |

– |

3–38 |

| A (%) |

1–8 |

1–19 |

11–38 |

23–34 |

11–17 |

3–43 |

*Carbon (C), Oxygen (O), Hydrogen (H), Sulfur (S), Nitrogen (N), Volatile matter (VM), Fixed carbon (FC), moisture (M), and ash (A) content.

Biomass is recognized as renewable energy carriers in terms of electrical or heat energy and transportation of fuels to replace the need of fossil fuels so that the harmful effects of environment can be limited but it all depends on quality and quantity of biomass feedstocks. Moreover, several characteristics should be kept in mind to evaluate the performance of any biomass feed which are listed below:

1 (i) Moisture content,

2 (ii) Calorific value,

3 (iii) Ash content,

4 (iv) Proportion of fixed carbon and volatile substances,

5 (v) Alkali metal content,

6 (vi) Cellulose/lignin ratio,

7 (vii) pH, etc.

1.2.2 Biomass Valorization Techniques

Biomass is converted into useful energy after applying various technologies into some valuable products like sugars, lignin, glycerol, etc. Generally, biomass is just decomposed/burned directly to generate energy in industries but in this process, fewer benefits can be achieved. Therefore, some important techniques which valorize the biomass utilization are employed such as pyrolysis, gasification, liquefaction, and biochemical processes [5]. These non-photocatalytic biomass valorization techniques can upgrade the quality and provide variety of products with maximum utilization of biomass feedstocks, if the participation of catalysts is possible.

Table 1.2 Biomass valorization techniques with important aspects [5].

| Biomass valorization techniques |

Feedstocks |

Temperature |

Products |

| Pyrolysis |

Cellulose, hemicelluloses, and lignin |

500 °C |

Charcoal, bio-oil and gaseous fuels |

| Gasification |

Combustible gas mixture |

800 °C |

Syngas |

| Liquefaction |

Agro-residue and algal biomass |

150–420 °C |

Liquid fuels such char, fertilizers, biofuels |

| Biochemical methods |

Organic biomass wastes, agricultural wastes |

Low temperature |

Biogas, bioethanol |

Pyrolysis converts wood biomass into solid (charcoal), liquid (bio-oil) and gaseous products by using fast pyrolysis mostly in the absence of oxygen at 500 °C. This technology is used in many industries on a wide scale [6, 7]. Gasification, on the other hand, is used to convert combustible gas mixture by partial oxidation process at high temperature approximately 800 °C. It produces an important fuel as syngas which is used in the production of methanol [8]. Liquefaction is a little different than the previous two techniques because of the conversion of biomass into valuable liquid fuels at low temperature within the range of 150–420 °C and high pressures as 1–240 bars [9, 10]. This valorization technology is more useful to improve yield through homogeneous/heterogeneous catalysts. Pyrolysis, gasification and liquefaction processes are considered as thermo-chemical conversion methods.

Читать дальше