C. Anandharamakrishnan - 3D Printing of Foods

Здесь есть возможность читать онлайн «C. Anandharamakrishnan - 3D Printing of Foods» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:3D Printing of Foods

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:3 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 60

- 1

- 2

- 3

- 4

- 5

3D Printing of Foods: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «3D Printing of Foods»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Explore the fascinating realm of 3D food printing and its applications 3D Printing of Foods

3D Printing of Foods

3D Printing of Foods

3D Printing of Foods — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «3D Printing of Foods», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

1.6.2 Components of a Typical 3D Printer

The basic components of a food 3D printer include printing movement arms, drive unit assisted with pulley mechanism, mechanical motors and feed rollers, material dispensing unit, temperature controlling system, printing head, printing platforms, and micro‐processing controller unit (Nachal et al. 2019).

1.6.2.1 Enclosure, Build Plate, and Guide Rails

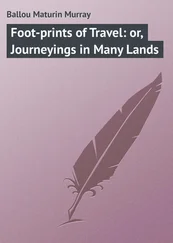

Frames are the supporting structures that carry the print head and carriage arms. Supporting frames are made from metal sheets with acrylic covering provided with nuts and bolts. It supports all the other accessory components which influence the printer’s stability and durability (Horvath 2014b). Based on the type of configuration of the 3D printer, the carriage arms differ in design and movement. The printing movement of the delta configuration is illustrated in Figure 1.6. These arms are facilitated with a motion mechanism achieved by linear motion guideways incorporated with GT2 belts and pulley controls. Belts assists in the smooth motion of respective arms in X , Y , and Z directions. In the case of cartesian type printers, the assembly is equipped with threaded steel rods on which the nuts are mounted that assist movement upwards and downwards along Z ‐axis (Huang 2018). The design of the print head varies with configuration type and it consists of a feeder system mounted with printing. The method of material dispensing also varies with the printing technologies and the description of which are explained in subsequent chapters.

Figure 1.6 Operation of delta type 3D printer. (a) Illustration of printing movements, (b), (c), and (d) pictorial views of printing movement following Pythagorean theorem.

Source: Derossi et al. (2019) / With permission of Elsevier.

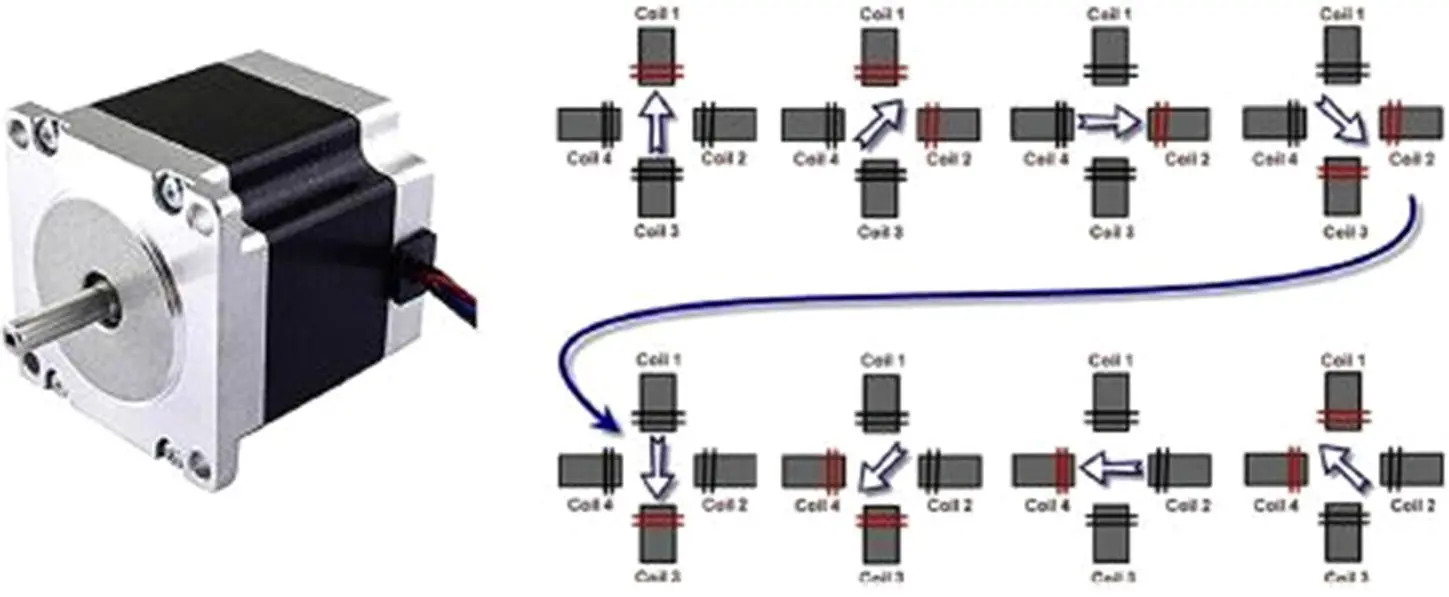

Figure 1.7 Stepper motor and its controlling mechanism.

Source: From Derossi et al. (2019) / With permission of Elsevier.

1.6.2.2 Mechanical Drive Systems

Irrespective of the type of structural configuration, the carriage arms are connected with a mechanical drive system for assisting its motion along X , Y , and Z directions. The drive systems consist of stepper motor‐operated in a pre‐defined step of pulses ( Figure 1.7). This step‐up mechanism aids in the rotation of printer arms in full degrees (Horvath 2014b). In general, the step‐up motors consist of a stator and rotor. Based on the structural configuration and working principle, stepper motors are of three types: permanent magnet stepper motor, variable reluctance stepper motor, and hybrid stepper motor. Among these, hybrid steppers are the most used stepper motors for 3D printing applications as it combines the advantageous features of permanent and variable stepper motors. Other characteristics that define a stepper motor includes its dimensions and rotating power (torque). The United States National Electrical Manufacturers Association (NEMA) declares a dimensional number to stepper motors named NEMA’s number based on the length and associated torque (Derossi et al. 2019). Apart from guiding the movement of carriages, stepper motors are also used for controlling the amount of material deposited during printing.

1.6.2.3 Microprocessor Controlling System

The motherboard is the heart of any 3D printer, responsible for coordinating the motion of components like the extruder, print bed, motors, and sensors. End stops are provided at all the carriages that act as sensors and allow 3D printers in identifying printing locations along the three axes, preventing it from moving past its limit otherwise it could result in hardware damages (Horvath 2014b). An interface arrangement of liquid crystal display (LCD) replicating rapid prototyper (REP RAP) full graphics smart controller is provided for controlling the printing process. Firmware refers to a set of computer programmes and instructions that connects the software with hardware (Horvath and Cameron 2015). The integration of software with hardware is detailed in the subsequent sections. A 3D printer with an LCD user interface can work as a standalone machine (using an SD card), i.e., it can be controlled without connecting to the computer. Although there are different kinds of user interfaces, the most common one is a basic LCD interface operated via a knob/dial. The printer can be operated with both LCD interface as well as universal serial bus (USB) assisted interface system connected with computer. Based on the working capacity and build size, the power requirement will vary. Often the printing process was carried out by connecting the printer to a computer via a USB cable. Files can be transferred and read either through an onboard controlling unit or through a USB external interface with a computer or through both of these (Horvath 2014a). The user interface/controller allows the user to send machine‐readable computer codes to the 3D printer and assists in changing some of the parameters during run time and move the print head along the X / Y / Z ‐axis. Most of the 3D printers are lab‐scale and can be operated at a power supply of 110 V/230 V AC, 50/60 Hz.

1.7 Software Requirements and Hardware Integration

3D model designing involves the creation of 3D models using designing software such as AutoCAD (Autodesk), SolidWorks (Dassault Systèmes), SketchUp (Trimble), Rhinoceros 3D (Robert McNeel & Associates), etc. All this software allows the users to design their desired 3D model. After designing, the stored file can be converted to STL format to fed to a 3D printer. Model building requires professional knowledge and skilled personnel to create the desired 3D model. However, with the advancements of technology designing models have become easier. Software like 3DSlash and Tinkercad are specially designed for students and beginners (Guo et al. 2019). It also allows the users to design their model on an online platform rather than downloading the software itself. Sometimes designing a 3D model may consume time for which software like Autodesk 123D catch helps in building a 3D model from the 2D image that saves time and aids in achieving the same precision as designing from 3D model software (Parras et al. 2018).

After model designing, the stored information of the 3D model in STL format is read/sliced in a layer‐by‐layer manner by using appropriate slicing software. The slicing process involves the extraction of actual information of the 3D model and transforms it into G and M codes which are readable by 3D printers. G codes are the numerical language generated by CAD software that is computer readable which guides the motors and assists in the motion of printing arms to the printing region. On the other hand, M codes are the auxiliary commands that aids and assists in machine functioning (Horvath and Cameron 2015). Most commonly used slicing software includes Cura, Simplify3D, Repetier, Slic3r, Craftware, SelfCAD, SliceCrafter, and Astroprint ( Table 1.1). Various process parameters that determine the final printing quality includes printing speed, retraction speed, layer height, printing temperature, nozzle size, number of outer shells, and infill percentage. Thus, slicing software allows the user to define the above printing parameters and aids in achieving good precise printing with higher resolution. All this setting information about the 3D model is fed to the printer in form of computer codes. G codes would have been written in numerical form and it slightly varies from printer to printer. The general commands commonly used are G0 (fast linear motion) and G1 (linear motion) which are referred to as the movement of the arms. For illustration, ‘G0 X nnn Y nnn Z nnn E nnn F nnn S nnn’ represents a command in which X nnn, Y nnn, and Z nnndenote the position of X , Y , and Z ‐axis; E nnndenotes the position of E axis, i.e. motion of print head stepper motor, F nnndenotes the speed of arms (mm min −1) and S nnndenotes the function to verify limit switch or not (S0 – do not check and S1 – check) (Guo et al. 2019). However, the entire 3D object can be printed using a complex command of G codes that requires more knowledge and skill in computer coding.

Читать дальшеИнтервал:

Закладка:

Похожие книги на «3D Printing of Foods»

Представляем Вашему вниманию похожие книги на «3D Printing of Foods» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «3D Printing of Foods» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.