NITIN KUMAR - Thermal Food Engineering Operations

Здесь есть возможность читать онлайн «NITIN KUMAR - Thermal Food Engineering Operations» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Thermal Food Engineering Operations

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 100

- 1

- 2

- 3

- 4

- 5

Thermal Food Engineering Operations: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Thermal Food Engineering Operations»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Presenting cutting-edge information on new and emerging food engineering processes,

, the first volume in the new series, “Bioprocessing in Food Science,” is an essential reference on the modeling, quality, safety, and technologies associated with food processing operations today.

This outstanding new volume:

Audience:

Thermal Food Engineering Operations — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Thermal Food Engineering Operations», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

The electric field in the homogeneous medium determined by:

E0 = ∇U, in which U is the electrostatic potential

So, generation of heat per unit volume would be;

where σ Ldefined as the electrical conductivity of dispersed or liquid materials

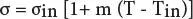

Changes in the conductance with the temperature for solid and liquid foods mostly taken in a linear form, described as follows:

wherein, σ indescribed as the electrical conductivity at the start point of temperature Tin and m is described as a constant of proportionality (°C -1)

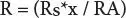

The resistance in the ohmic heating defined as:

where R is total heat resistance in ohms, R s(ohms per meter) is specific product resistance, x(m) is the gap between the electrodes, and A(m 2) is the electrode area.

1.3.4.2 Advantages and Disadvantages

Advantages

1 Particulate foods less than one cubic inch considered appropriate in the resistance heating process; solids content range of 20-70% is deemed to be significant in the liquid-particle mixture flow reaching the plug flow.

2 Mixtures of particles and liquids are evenly heated in some situations because the properties of fluids and the particles are similar such as viscosity, conductance, heat capacity, flow rate, etc.

3 The required temperatures can be achieved rapidly in the case of ultra-high temperature processes as well.

4 There is no hot surface for heat transfer, so the risk from flaming or overprocessing of the product is low.

5 High-energy conversion efficiency.

6 Capital cost relatively low.

7 Colour and nutritional value of food retained.

8 System is environment-friendly.

9 Process control is better than the conventional heating method and more straightforward as well.

10 Reduced fouling compared to that seen in conventional heating.

11 It is an exemplary process for shear-sensitive products since the flow rate is low.

12 Fast and uniform processing of liquid and solid phases which reduces any harm due to heat and retention of nutrients is there [34]. Products treated in ohmic heating have better textural properties than traditional heating procedures.

13 Rapidly heated and heating is volumetric in nature.

14 Easily controllable.

15 Rapid inactivation of microbes and enzymes [46].

16 Storage and distribution in ambient temperature combined with the aseptic filling system.

Disadvantages

1 Installation cost and operation costs are high for ohmic heating systems compared to conventional processing methods.

2 Fat globules present in food are not appropriately heated or heated slowly in ohmic systems because of no conductance (since no salt and water presence) [34].

3 Longer processing time may be required in heating systems to achieve appropriable alterations in food materials, e.g., process of gelatinization of starch.

4 Nutritional and physical attributes of the material bear alterations in the rapid ohmic heating process.

5 Ohmic electrodes may get corroded after the cooking process, and hence final product may also get affected.

6 In continuous ohmic textural softening in beans; changes in the uniformity of product (volume enlargement) were seen, low quality of duct plugging (because of the large size of soybeans) [22, 23].

7 Change in the cell membrane of raw produce due to heat transfer by electro-thermal effect resistance heating, particularly at a low frequency.

8 Loss in Nutritional values and increase in BOD of effluents, e.g., cell-based material coming out from the heating medium is inappropriate for some products or processes

9 Capital funding and safety issues [21–23].

10 Inert electrode material.

11 No proper control in the electrical conductance of all the food constituents because then different heating rates would be there for various components [54].

12 Unavailability of data on essential parameters affects the heating, such as dwell time, direction, level of loading.

13 Inappropriate temperature conformance technology to identify cold/hot locations spot [54].

1.3.4.3 Applications

Ohmic heating has several uses in the food processing industry. It has successful applications in various food products (solids or liquid/fluids or a mixture of both); like juices, fruits and vegetables, stews, meats, sauces, pasta, soups, and seafood.

In the initial years, the application of ohmic heating in beetroots resulted in improvement in the diffusion of betanin from the beetroot tissue, and its concentration and electric field strength were studied. Then studies carried out on radish in which heating rate was analyzed concerning frequency, which stated an increase in AC frequency leads to an increase in heating rate. Also, electrically heated foods are influenced by their mass transfer properties.

With time, its potential applications discovered in a huge amount such as in blanching, dehydration, fermentation, evaporation, extraction, etc.

The electric resistance heating process provides a chance for the production of new, high value-based, shelf-stable food products of quality that could not be realized before with current sterilization technology [54].

1 Blanching: Ohmic heating can enhance process efficiency in blanching, e.g, Ohm heating has rapid and uniform heating; hence there is no need to dice vegetables due to an effective method of ohmic heating, which has a fast turnaround time and less surface area. Blanching of mushrooms with the application of ohmic heating resulted in shrinking at lower temperatures with less water use compared with conventional ones.

2 Evaporation: Using electric resistance heating results in a threefold increase in the evaporation rate and hence improved product quality.

3 Dehydration: Improved dehydration rates of vegetable tissues, for example, Treating (with ohmic heating) sweet potatoes before dehydration significantly speeds up hot air drying compared to the traditionally processed samples. It also has seen the acceleration in vacuum drying rate of sweet with minimal ohmic pretreatment.

4 Fermentation: Enhanced extraction of components from different food products. For example, Ohmically pretreated apple tissue showed an increase in the yield of mechanical juice extraction. Also, ohmically treated rice bran showed an increased extraction of RBO (rice bran oil) (particularly at lower frequencies (say, 1Hz)) using ohmic heating.

5 Microbial Inactivation: Resistance heating is fatal to almost all microorganisms. Lower D-value and z-values were recorded in studies for microbial inactivation. A study by [71] resulted in a higher microbial death rate deactivating viable milk aerobes and S. Thermophilus using ohmic heating. Death of microbes in ohmic heating is due to the higher temperatures or increased electric field strength [34].

6 Enzymes Inactivation: Electric resistance heating generates an electric field which is found to be efficient for rapidly inactivating the enzymes such as lipoxygenase, polyphenol oxidase, pectin esterase than traditional heating systems [34]. For example,(i) Dynamics of polyphenol oxidase deactivation during ohm heating of grape juice studied, and ohmic heat treatment at various potential gradients applied to grape juice at specific temperatures. Changes in PPO enzymatic activity were noted.(ii) Declination in the activity of exogenic pectin methylesterase enzyme present in cloudberry jam and apple juice using ohmic heating and it follows rate law.(iii) Resistance heating with continuous alternating current resulted in successful deactivation of Bacillus subtilis spores in orange juice in a short duration of time, using a pressurized electric sterilization system; also reduction in peculiar smell and loss of ascorbic acid observed in the studies.

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Thermal Food Engineering Operations»

Представляем Вашему вниманию похожие книги на «Thermal Food Engineering Operations» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Thermal Food Engineering Operations» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.