NITIN KUMAR - Thermal Food Engineering Operations

Здесь есть возможность читать онлайн «NITIN KUMAR - Thermal Food Engineering Operations» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Thermal Food Engineering Operations

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 100

- 1

- 2

- 3

- 4

- 5

Thermal Food Engineering Operations: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Thermal Food Engineering Operations»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Presenting cutting-edge information on new and emerging food engineering processes,

, the first volume in the new series, “Bioprocessing in Food Science,” is an essential reference on the modeling, quality, safety, and technologies associated with food processing operations today.

This outstanding new volume:

Audience:

Thermal Food Engineering Operations — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Thermal Food Engineering Operations», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

Disadvantages:

1 Risk of arching

2 The frequency band is narrow

3 Occupy large floor space [59]

4 The high initial capital cost of equipment and operating cost

5 Fluctuations in electrical costs

6 Different designs and applicators required to meet product-specific requirements [79]

7 Reduced power density [54]

Using a good quality of applicator’s design with specific fine-tuning, technologically advanced tools and highly skilled technicians sums up to be an efficient RF system.

An exemplary RF system would have greater penetration depth, the volumetric heating advantage of dielectric heating than other techniques, along the hybrid systems produce effectual, swift, and graded results [79].

1.3.3.3 Applications

RF dielectric has various applications in lumber, textile, and food industries, etc.

RF treatment is giving after the biscuits baked in cereals, to dry foods (herbs, spices, vegetables, potato products, pasta products), thawing, etc. The efficient role of RF is seen in moisture removal during the baking process.

It is also used for the thawing of meats and fish in large amounts, and its volumetric nature enhances the acceleration in the process without affecting the distribution of temperature throughout the product [54].

1 i) RF application in Fresh food processing:In Fresh fruits: A significant reduction in brown rot was seen when dielectric treatment (27.12MHz, 15kW) was given with hot water. Infection in peaches being reduced using RF heating and brown rots controlled in nectarines. In Fresh Vegetables: Vacuum-packaged Caixin (a green leafy vegetable) with an adequate microbial count resulted in a significant decrease in the number using ohmic heating with a 20 mm gap in electrode without affecting any other property of the material [26].

2 ii) RF heating on fresh meats showed results when treated while meat processing, as reduced E. coli count, shelf life extension wherein it has higher heating uniformity and had a shorter cooking time [31, 75].

3 iii) Significant reduction of A. parasiticus in corns seen using a combination of RF heating with hot air [25, 26].

4 iv) RF heating system in food industries used to inactivate bacteria in wheat flour, caixin, peach, pepper spice, apple juice, stone fruit, almonds, ham, etc., using free-running or 50Ω type system at a frequency of 27.12MHz [31].

5 v) It also used for disinfestation of rice, lentils, legumes, walnuts, etc., using a free-running oscillator at a frequency of 27.12MHz [31].

6 vi) Also used in cooking purposes in beef, egg white, meat emulsion, pork ham, turkey, meat, etc., using free running or 50 ohms at a frequency of 27.12MHz.

7 vii) Used in the thawing of pork, tuna fish, beef using 50 ohms at a frequency of 13.56-27.12MHz [31].

8 viii) For enzyme inactivation in miso paste, apple, myrosinase using 50 ohms at 27.12MHz frequency.

9 ix) Application in roasting and drying of nuts as well for improving energy efficiency and product quality [31].

10 x) Dry-blanching with RF was observed to be an efficient method to treat products in which a 95% reduction in enzyme activity (POD) was seen in 3-7 min. time with a gap of 8-8.6 cm; rehydration enhancement, retention of the textural properties were also recorded [24].

11 xi) Application in wood drying (10-30MHz), agricultural product drying (27MHz), food drying, etc. [79].

12 xii) Production of Biodiesel from moist microalgae: Cell disruption of Algae done using RF heater at a frequency of 27.12MHz and maximum power output of 6kW and the esterification/transesterification reactions were also promoted [48].

1.3.4 Ohmic Heating

1.3.4.1 Principal and Mechanism

Heating technology has observed some recent advances with the following technology development, viz Dielectric heating (Radiofrequency and microwaves), induction and Ohmic heating. Ohmic Heating or joule heating is electro-heating, or electroconductive heating or direct electric resistance heating in which heat generated within the food material is due to the generation of alternating electric current passed through the food material. In 1900, the Ohmic heating technique was utilized for the Pasteurization of infant milk. In the early twentieth century, the electro-pure process was relevant commercially, but later with time, it became prevalent during the 1980s.

The food itself acts conductor in electric resistance heating as the voltages are applied, the current between the electrode and ground helps in determining the resistivity of the food as per Ohm’s law. Increasing the current or voltage, thereby increase in temperature increases the conductivity of foods [54].

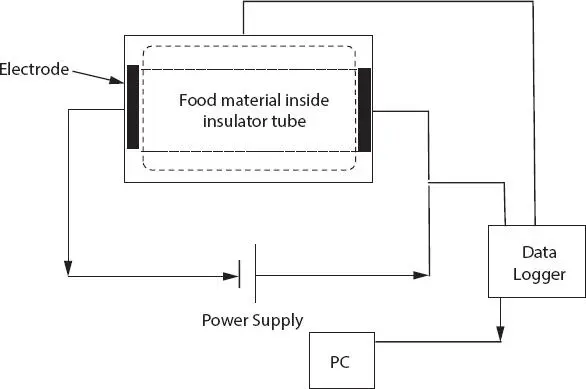

In Ohmic heating, unlike other thermal methods, the electrode is in contact with food; less frequency is applied compared to the frequency of radio or microwaves, and the waveform is usually a sine wave. Resistance heating systems help with the production of products with high storage stability through proper maintenance of food in terms of color and nutritional value [34]. Figure 1.2depicts the circuit diagram of static (batch type) resistance heating process [46].

Ohmic heating is defined as the amount of heat generated in which electrical current passes through the food and current resisting the flow of electricity. Its principle is based on the direct application of Ohm’s Law, wherein, the current through the conductor between the two points is directly proportional to the voltage.

Figure 1.2 Circuit diagram of static (batch type) resistance heating process [46].

Heat is generated internally due to the alternating current applied to the food, and the OH ratio is directly dependent on the electrical conductivity of food.

Voltage by the alternating current applied at both ends of the electrode, which interacts directly with the supplied food. Food treated in the ohmic heating chamber should come in contact with the electrodes. Since food contains the right amount of ionic salts and water molecules, electrical energy is converted into thermal energy to generate heat internally, and almost all energy inputs convert to heat without a loss factor. The heat generated can be used for other food processes such as Pasteurization, sterilization, and blanching related to OH applications. Resistance heating devices instrumentation includes an electrode (electrodes may be of stainless steel, aluminum, titanium, or platinum-coated titanium), power supply, an insulating tube or container or a heating chamber trapping the food sample inside it, data logger system, a current sensor, a thermocouple, and a Personal computer. The significant parameters involved are electrode configuration (flow of current across or parallel to the product flow direction), the gap between the two electrodes, heater shape, AC frequency, the voltage applied, the speed of the product, a supply of electricity, amount of charge per unit time. Some other factors considered are the type of product and its properties in particular specific conductance and rate of heating; total solids in food material, the heat capacity, viscousness of the material, density, the size and shape of the particles, and inclination of an electric field. The electric field intensity, E and σ, the electrical conductance, and Q are the heating rate that is directly proportional to the field strength and the square of the electrical conductivity. The increased temperature, conductance determine the efficiency of OH and the values of temperature, voltage, current, the time displayed in the data acquisition system [61].

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Thermal Food Engineering Operations»

Представляем Вашему вниманию похожие книги на «Thermal Food Engineering Operations» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Thermal Food Engineering Operations» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.