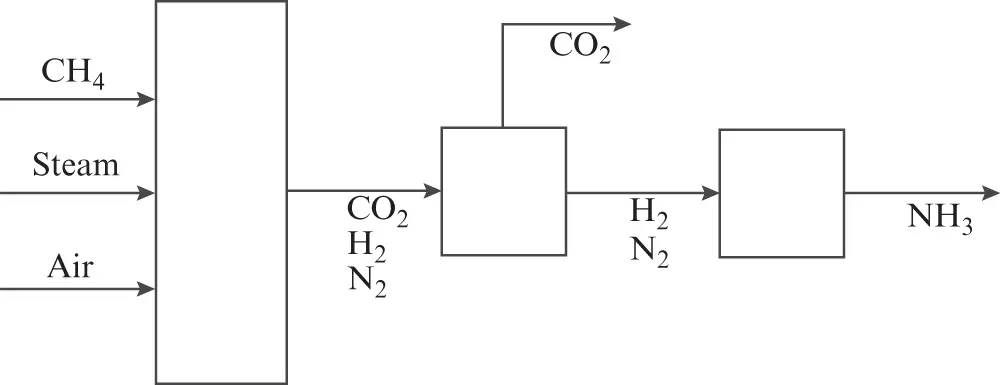

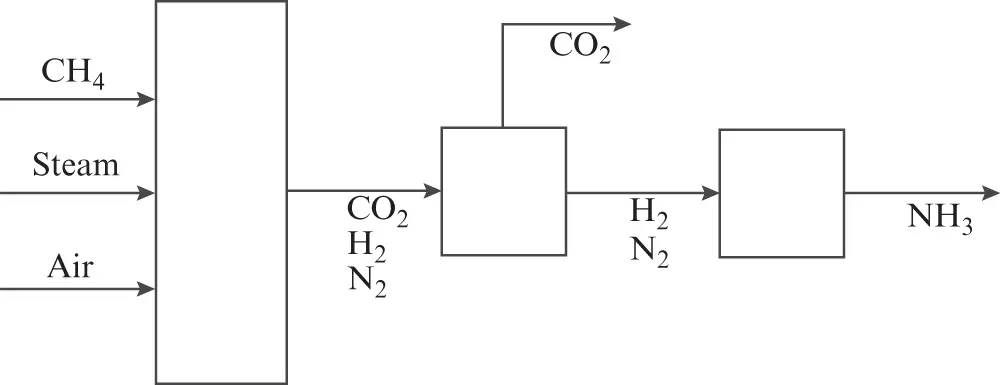

Sketch a flow diagram for this process.

Solution . See Figure 3.3 for a simplified process flow diagram for this ammonia manufacturing process.

Figure 3.3 Simplified process flow diagram for Illustrative Example 4.

3.9.5 Illustrative Example 5

All measurements and calculations are subject to two broad classes of errors: determinate and indeterminate . Any error that is discovered and allowed for in magnitude and sign in the form of a correction allowing for its effect is a “determinate error.” All errors that either cannot be or are not properly allowed for in magnitude and in sign are known as “indeterminate errors.” A particularly important class of indeterminate errors is that of accidental errors. Qualitatively discuss these two error types.

Solution . Determinate errors are systematic errors that can be discovered and corrected. Determinate errors include instrument errors , i.e. calibration errors, power fluctuations, method errors , i.e. sampling problems, inconsistent recovery, and personal errors , i.e. errors that occur when measurements require judgment, color interpretation, etc. Determinate errors can be corrected via proper instrument calibration, method development, or training. To illustrate the nature of indeterminate errors, consider the very simple and direct measurement of temperature. Suppose that several independent readings are made and that the temperature varies by 0.1°F. When the results of the different readings are compared, it may be found that even though they have been performed very carefully, they may differ from each other by several tenths of a degree. Experience has shown that such deviations are inevitable in all measurements and that they result from small unavoidable random errors of observation due to the sensitivity of measuring instruments and the keenness of the sense of perception. Such errors are due to the combined effect of a large number of undetermined causes and they can be defined as accidental or indeterminate errors (Prochaska and Theodore 2018; Theodore and Behan 2018).

1 The suspended particulate concentration in a brackish water source has been determined to be 27.6 mg/L. Convert this value to units of µg/L, g/L, lb/ft3, and lb/gal.

2 As part of a plant’s proposed desalination process cold seawater is mixed with recycled water from a dehumidifier (D), and the mixture then passes through a waste heat boiler (W), which uses air (A) as the heat transfer medium. The hot air and water mixture then pass through a humidifier (H), in which humid air is generated and then passed through the dehumidifier (D) and condensed to form potable water. Prepare a simplified process flow diagram for this process.

3 Precision and accuracy are two terms used to describe measurements and measurement error. Discuss the difference between these two terms in the context of quantitative parameter measurements.

4 A common English volumetric flowrate unit in water and wastewater treatment applications in the United States is million gallons per day, MGD. A desalination plant is being designed for an average flow of 25 MGD. Determine the plant’s capacity in other common volumetric flow units shown in Table 3.4of gpm, cfs, and m3/d.

5 The concentration of many organic chemicals at which they are potentially toxic or hazardous to human health or the environment is often very low. Many emerging contaminants, for example PFAS (per- and polyfluoroalkyl substances) are very persistent in the environment and in the human body, and there is evidence that exposure to PFAS can lead to adverse human health effects. The drinking water health advisory for two of these PFAS compounds, PFOA and PFOS, is 70 parts/trillion or 70 ng/L. For these two PFAS compounds, determine the following: (1) what is their daily dose at the health advisory limit if the average adult water consumption rate is 1 L/d? (2) if a desalination plant is treating combined brackish water and recharged treated wastewater at a ratio of 50 to 1 on a volume basis, the concentration of PFOA + PFOS in the treated wastewater is 8 ng/L, and the plant is expected to provide 98% PFAS removal, what is the margin of exposure (MOE = NOEL/Actual Dose, g/d) if the health advisory limit dose from (1) is assumed to be the no-observed-adverse-effect level (NOEL)? (3) If the MOE is recommended to be > 100, comment on the MOE for this facility and indicate any corrective action or modified operating conditions that should be implemented to ensure the safety of this produced water supply.

1 Abulencia, P. and Theodore, L. (2007). Fluid Flow for the Practicing Chemical Engineer. Hoboken, NJ: John Wiley & Sons.

2 Dupont, R.R., Ganesan, K., and Theodore, L. (2016). Pollution Prevention, Industrial Ecology, Green Science and Engineering, and Sustainability. Boca Raton, FL: CRC Press/Taylor and Francis Group.

3 Felder, R. and Rousseau, R. (1986). Elementary Principles of Chemical Processes, 2nd Edition. Hoboken, NJ: John Wiley & Sons.

4 Green, D.W. and Perry, R.H. (2008). Perry's Chemical Engineer's Handbook, 8th Edition. New York, NY: McGraw-Hill.

5 Kauffman, D. (1992). Process Synthesis and Design, a Theodore Tutorial. East Williston, NY: Theodore Tutorials. Originally published Research Triangle Park, NC: USEPA/APTI.

6 McCabe, W., Smith, J., and Harriot, P. (1993). Unit Operations of Chemical Engineering, 5th Edition. New York, NY: McGraw-Hill.

7 Prochaska, C. and Theodore, L. (2018). Introduction to Mathematical Methods for Environmental Engineers and Scientists. Salem, MA: Scrivener/Wiley.

8 Reynolds, J. (1992). Material and Energy Balances, a Theodore Tutorial. East Williston, NY: Theodore Tutorials. Originally published Research Triangle Park, NC: USEPA/APTI.

9 Theodore, L. (2011). Heat Transfer for the Practicing Chemical Engineer. Hoboken, NJ: John Wiley & Sons.

10 Theodore, L. (2014). Chemical Engineering: The Essential Reference. New York, NY: McGraw-Hill.

11 Theodore, L. and Behan, K. (2018). Introduction to Optimization for Chemical and Environmental Engineers. Boca Raton, FL: CRC Press/Taylor and Francis Group.

12 Theodore, L. and Ricci, F. (2010). Mass Transfer Operations for the Practicing Engineer. Hoboken, NJ: John Wiley & Sons.

Конец ознакомительного фрагмента.

Текст предоставлен ООО «ЛитРес».

Прочитайте эту книгу целиком, купив полную легальную версию на ЛитРес.

Безопасно оплатить книгу можно банковской картой Visa, MasterCard, Maestro, со счета мобильного телефона, с платежного терминала, в салоне МТС или Связной, через PayPal, WebMoney, Яндекс.Деньги, QIWI Кошелек, бонусными картами или другим удобным Вам способом.