Department of the Army

U.S. ARMY COMBAT PISTOL TRAINING HANDBOOK

This publication applies to the Active Army, the Army National Guard (ARNG), the National Guard of the United States (ARNGUS), and the US Army Reserve (USAR). It provides guidance on the operation and marksmanship of the M9, 9-mm pistol and the M11, 9-mm pistol. It reflects current Army standards in weapons qualification. It is a guide for the instructor to develop training programs, plans, and lessons that meet the objectives of the US Army Marksmanship program for developing combat-effective marksmen. The Soldier develops confidence, knowledge, and skills by following the guidelines in this manual.

The proponent of this publication is the US Army Infantry School. Send comments and recommendations on DA Form 2028 directly to Commandant, U.S. Army Infantry School, ATTN: ATSH-ATD, Fort Benning, GA 31905, or by email to doctrine@benning.army.mil.

Unless this publication states otherwise, masculine nouns and pronouns refer to either gender.

CHAPTER 1

COMPONENTS AND FUNCTIONING

This chapter describes the M9 and M11 semiautomatic pistols, their maintenance requirements, and their operation and functioning.

SECTION I. DESCRIPTION AND COMPONENTS

The M9 (Figure 1-1) and M11 (Figure 1-2) pistols are 9-mm, semiautomatic, magazine-fed, recoil-operation, double-action weapons chambered for the 9-mm cartridge.

Figure 1-1. 9-mm pistol, M9.

Figure 1-2. 9-mm pistol, M11.

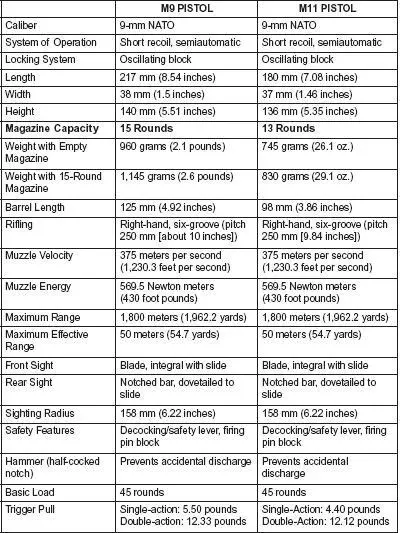

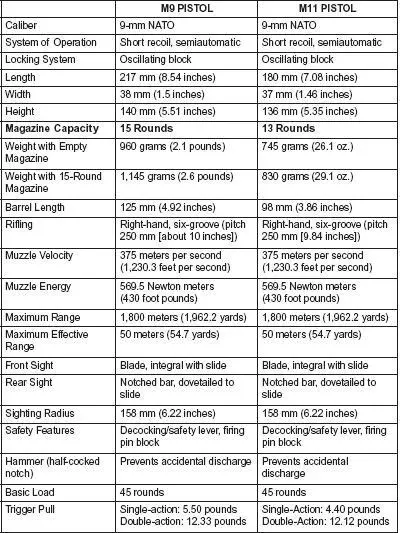

Table 1-1 summarizes equipment data for both pistols.

Table 1-1. Equipment Data, M9 and M11 pistols.

NOTE:For additional information on technical aspects of the M9 pistol, see TM 9-1005-317-10. For additional information on technical aspects of the M11 pistol, see TM 9-1005-325-10.

WARNING

The half-cocked position catches the hammer and prevents it from firing if the hammer is released while manually cocking the weapon. It is not to be used as a safety position. The pistol will fire from the half-cocked position if the trigger is pulled.

The major components of the M9 (Figure 1-3) and M11 (Figure 1-4) pistols are:

a. Slide and Barrel Assembly:Houses the firing pin, striker, and extractor. Cocks the hammer during recoil cycle.

b. Recoil Spring and Recoil Spring Guide:Absorbs recoil and returns the slide assembly to its forward position.

c. Barrel and Locking Block Assembly:Houses cartridge for firing, directs projectile, and locks barrel in position during firing.

d. Receiver:Serves as a support for all the major components. Houses action of the pistol through four major components. Controls functioning of the pistol.

e. Magazine:Holds cartridges in place for stripping and chambering.

Figure 1-3. Major components, M9.

Figure 1-4. Major components, M11.

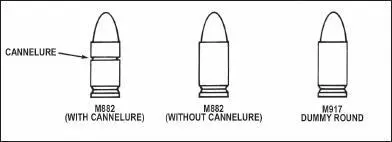

M9 and M11 pistols use several different types of 9-mm ammunition. Soldiers should use only authorized ammunition that is manufactured to US and NATO specifications.

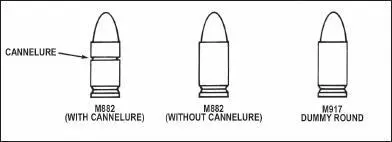

a. Type and Characteristics.The specific type ammunition (Figure 1-5) and its characteristics are as follows:

(1) Cartridge, 9-mm ball, M882 with/without cannelure.

(2) Cartridge, 9-mm dummy, M917.

WARNING

Do not fire heavily corroded or dented cartridges, cartridges with loose bullets, or any other rounds detected as defective through visual inspection.

Figure 1-5. Ammunition.

b. Care, Handling, and Preservation.

(1) Protect ammunition from mud, sand, and water. If the ammunition gets wet or dirty, wipe it off at once with a clean dry cloth. Wipe off light corrosion as soon as it is discovered. Turn in heavily corroded cartridges.

(2) Do not expose ammunition to the direct rays of the sun. If the powder is hot, excessive pressure may develop when the pistol is fired.

(3) Do not oil or grease ammunition. Dust and other abrasives that collect on greasy ammunition may cause damage to the operating parts of the pistol. Oiled cartridges produce excessive chamber pressure.

Maintenance procedures include clearing, disassembling, inspecting, cleaning, lubricating, assembling, and checking the functioning of the M9 or M11 pistol.

The first step in maintenance is to clear the weapon. This applies in all situations, not just after firing. Soldiers must always assume the weapon is loaded. To clear the pistol, perform the following procedures.

a. Place the decocking/safety lever in the SAFE down position.

b. Hold the pistol in the raised pistol position.

c. Depress the magazine release button and remove the magazine from the pistol.

d. Pull the slide to the rear and remove any chambered round.

e. Push the slide stop up, locking the slide to the rear.

f. Look into the chamber to ensure that it is empty.

To disassemble the pistol, perform the following procedures.

a. Depress the slide stop and let the slide go forward.

b. Hold the pistol in the right hand with the muzzle slightly raised.

c. Press the disassembly lever button with the forefinger.

d. Rotate the disassembly lever downward until it stops.

e. Pull the slide and barrel assembly forward and remove it from the receiver.

f. Carefully and lightly compress the recoil spring and spring guide. At the same time, lift up and remove them.

g. Separate the recoil spring from the spring guide.

h. Push in on the locking block plunger while pushing the barrel forward slightly.

i. Lift and remove the locking block and barrel assembly from the slide.

Inspection begins with the pistol disassembled in its major components. Shiny surfaces do not mean the parts are unserviceable. Inspect all surfaces for visible damage, cracks, burrs, and chips.

1-7. Cleaning, Lubrication, and Preventive Maintenance

The M9 or M11 pistol should be disassembled into its major components and cleaned immediately after firing. All metal components and surfaces that have been exposed to powder fouling should be cleaned using CLP on a bore-cleaning patch. The same procedure is used to clean the receiver. After it has been cleaned and wiped dry, a thin coat of CLP is applied by rubbing with a cloth. This lubricates and preserves the exposed metal parts during all normal temperature ranges. When not in use, the pistol should be inspected weekly and cleaned and lubricated when necessary.

Читать дальше