1 ...8 9 10 12 13 14 ...19

1.7 How Knowledge and Data Can Be Used to Maximize Profit

New ways of doing business are key for survival. Intelligent industries are those who can adapt quickly to this knowledge and innovation era. However, this needs a complete mindset change. How we generate useful knowledge and integrate it with business decisions is the real challenge of today's CPI. A new look to the old problems is absolutely necessary. A new way to increase equipment reliability, novel methods for process data monitoring, and a new emphasis on real‐time optimization are what is now needed. How data and knowledge can be used to maximize profit is the real key driver and all the chapters of this book are dedicated to that. Companies took multi‐faceted a completely new advanced approach to deal with this challenge. Some of the common solutions Global good companies have implemented are as follows:

Real‐time optimization (RTO) and advanced process control (APC) are implemented for real‐time optimization of plant. These tools ensure running the plant with simultaneous multiple constraints.

Implementation of an advanced artificial intelligence (AI) base, online data monitoring, and fault diagnosis detect any abnormality of process equipment at its incipient stage.

All these plants run 25–50% more capacity than their design capacity.

Online equipment reliability monitoring systems are implemented.

Risk‐based inspection systems are in place.

Online supply chain management system.

SAP‐based reliability centered maintenance practice.

A management framework to encourage people participation and to tap their ideas for small improvements in the plant.

1 Lahiri, S.K. (2017a). Front matter. In Multivariable Predictive Control (pp. i–xxxiii). https://doi.org/10.1002/9781119243434.fmatter.

2 Lahiri, S.K. (2017b). Introduction of model predictive control. In Multivariable Predictive Control (pp. 1–21). https://doi.org/10.1002/9781119243434.ch1.

2 Big Picture of the Modern Chemical Industry

2.1 New Era of the Chemical Industry

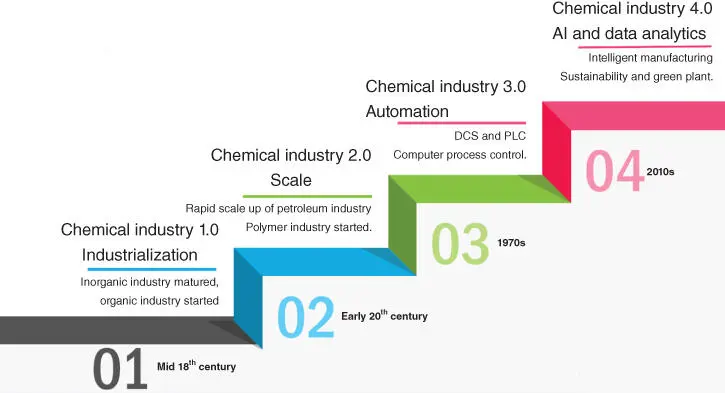

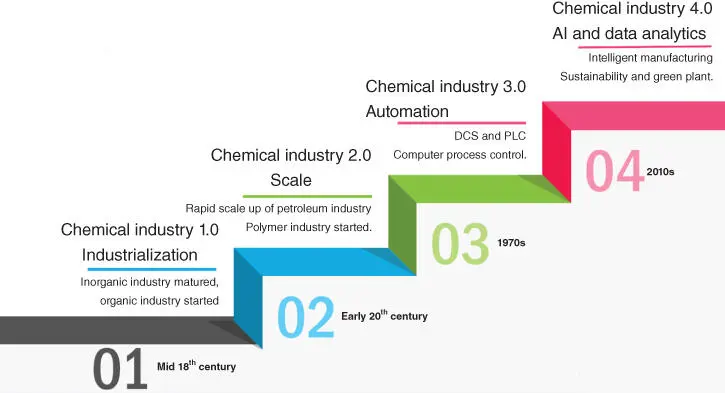

Since 1746, evolution of the modern chemical industry can be divided into four distinct stages of development: the industrialization era (chemical industry 1.0), the scale and capacity building era (chemical industry 2.0), and the automation and computerization era (chemical industry 3.0). Currently the chemical industry is slowly entering into a new era called data analytics and the artificial intelligence (AI) stage (4.0). Disruptive technologies like artificial intelligence, machine learning, big data analytics, and the internet of things (IoT) have already entered inside the chemical process industries and are already changing the rule of the chemical business (Ji, He, Xu, and Guo, 2016). Their influence is starting to see benefits in a significant improvement in production efficiency, energy utilization, optimization of the entire manufacturing process, integration of the supply chain, new product development, product delivery speed, etc. Figure 2.1shows the development stages of the chemical industry.

Figure 2.1Developing stages of the chemical industry

2.2 Transition from a Conventional to an Intelligent Chemical Industry

The recent advances of these disruptive digital technologies give birth to a new generation of intelligent chemical industries (Ji et al., 2016). The old method of doing business by the conventional chemical industry are slowly becoming obsolete. Distinct features of a new generation of intelligent chemical industries are given below (but are not limited to these):

A new generation of intelligent chemical industries use data analytics to take informed decisions in every phase of business, be it manufacturing, marketing, or R&D (research and development). These intelligent chemical industries develop a complete infrastructure of digital platforms to collect and analyze data and integrate it with business processes. This is called digital transformation.

They generate knowledge from the available data by using artificial intelligence‐based algorithms. This knowledge is used to integrate shareholder value, market demands, and sustainable development.

Manufacturing facilities of these new generation of chemical industries are transformed from island mode to integrated mode. Operation of the supply chain, manufacturing facility, marketing, and R&D are integrated to leverage a larger optimization scope.

The process control of these process industries is not confined to normal PID (Proportional, Integration and derivative) control but expands to advance process control and real‐time optimization covering the production process, entire marketing, and supply chain operation.

With the help of data analytics and artificial intelligence‐based algorithms these chemical industries develop a knowledge‐based decision‐making capability in every aspect of business and make themselves better prepared to handle more stringent environmental requirements and changing customer needs.

The comparisons between an intelligent chemical industry and the conventional chemical industry are listed in Table 2.1(Ji et al., 2016).

2.3 How Will Digital Affect the Chemical Industry and Where Can the Biggest Impact Be Expected?

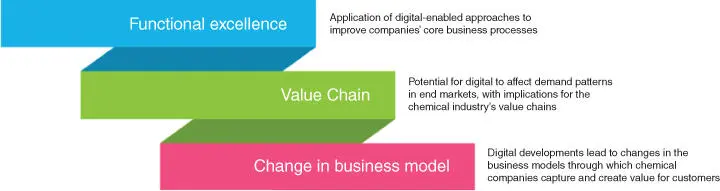

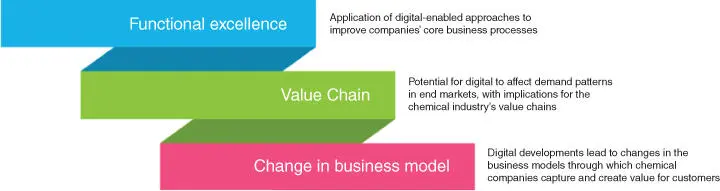

The global management firm M/s Mckinsey has studied and reported that digital transformation is changing the entire chemical business in three major ways, as depicted in Figure 2.2(Klei et al., 2017).

Table 2.1Comparisons between smart and conventional chemical industries

| Items |

Conventional chemical industry |

Intelligent chemical industry |

| Integration mode |

Integration for processes |

Integration of supply chain network |

| Optimization goals |

Profit optimization on specific conditions |

Profits optimization considering market demand, device status, energy conservation and emissions reduction |

| Optimization patterns |

Serial mode conducted offline |

Synchronous optimization of decision‐making and control adjustment employed online |

| Technical economic feature |

Large‐scale |

Equilibrium between large‐scale and necessary flexibility |

| Operation mode |

Specialized manufacturing |

Combination of manufacturing and service |

| Decision factors |

Operational and technical factors |

Users' requirements, products, quality standard, operating condition, resource, system reliability status |

| Control mode |

Discrete control |

Advanced process control |

| Intelligent degree |

Low level |

Artificial intelligence embedded in the process optimization control |

| Control platform |

Discrete control system |

Contemporary integrated process system |

| Flexibility |

Limited flexibility, adaptive scope and function redundancy |

More flexible configuration, adaptive to multiple optimization control modes |

| Data supporting |

Local small data |

Big data |

| Algorithm |

Traditional statistical analysis |

Statistical analysis, data mining, AI and visualization techniques |

Figure 2.2Three major ways digital transformation will impact the chemical industry

Читать дальше