Geoff Klempner - Handbook of Large Hydro Generators

Здесь есть возможность читать онлайн «Geoff Klempner - Handbook of Large Hydro Generators» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

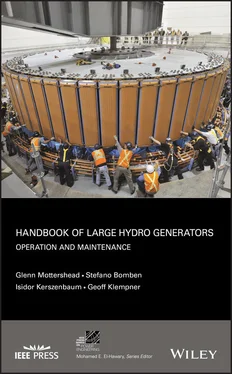

- Название:Handbook of Large Hydro Generators

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:4 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

Handbook of Large Hydro Generators: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Handbook of Large Hydro Generators»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Handbook of Large Hydro Generators: Operation and Maintenance Written with a machine operator and inspector in mind,

:

Instructs readers how to perform complete machine inspections, understand what they are doing, and find solutions for any problems encountered Includes real-life, practical, field experiences so that readers can familiarize themselves with aspects of machine operation, maintenance, and solutions to common problems Benefits experienced and new power plant operators, generator design engineers and operations engineers. Is authored by industry experts who participated in the writing and maintenance of IEEE standards (IEEE C50.12 and C50.13) on the subject

is an ideal resource for scientists and engineers whose research interest is in electromagnetic and energy conversion. It is also an excellent book for senior undergraduate and graduate students majoring in energy generation, and generator operation and maintenance.