Figure 1‐1. Automated test setup.

( Source : Courtesy of Instron.)

Figure 1‐2. Automated notcher.

( Source : Courtesy of Instron.)

Figure 1‐3. Twin‐bore capillary rheometer.

( Source : Courtesy of Instron.)

Figure 1‐4. Instrumented impact tester.

( Source : Courtesy of Instron.)

While budget cutbacks and reduced staffing levels have affected nearly every segment of the plastics industry, large research centers operated by major manufacturers have been particularly under scrutiny. As a result, the outsourcing of analytical and testing services to independent laboratories has been increasing. According to the latest estimate, nearly $10 billion in analytical services is currently being outsourced, and growth of more than 20 percent per year is anticipated. By using outside laboratory services, a company can reduce large investment in underutilized lab instrumentation, reduce expensive overheads, and keep in‐house laboratory staff focused on higher‐value development and problem‐solving work.

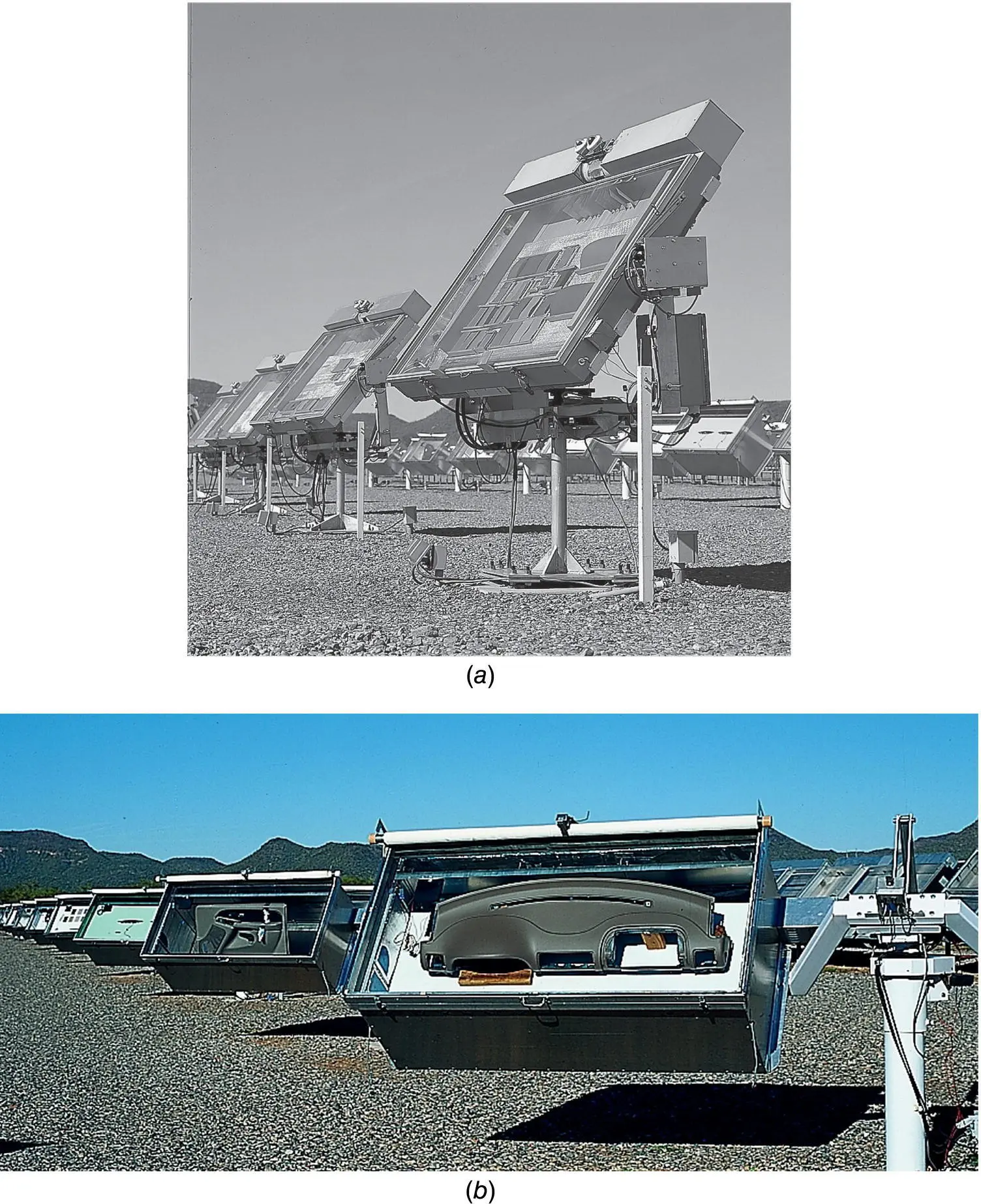

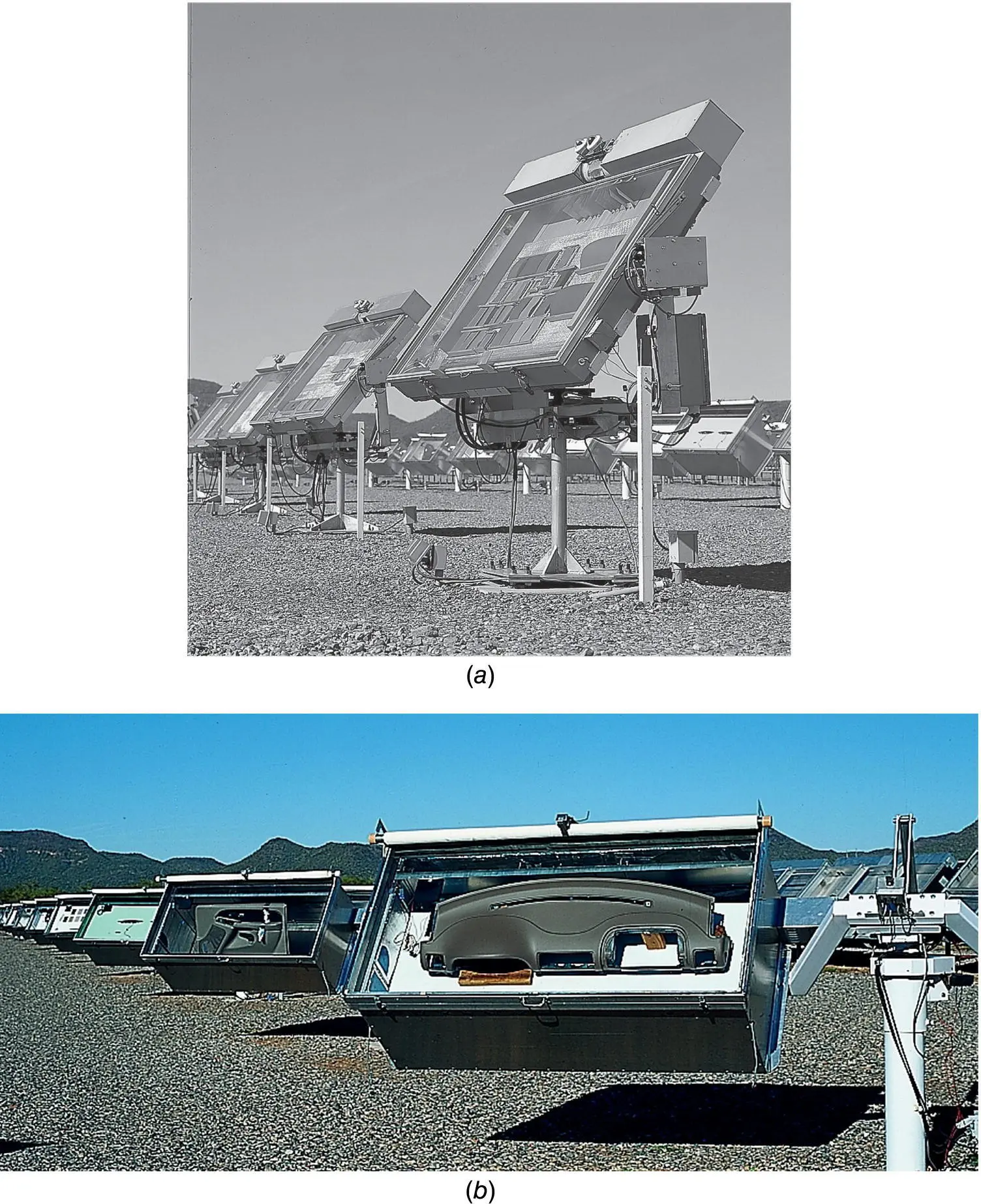

Figure 1‐5. Outdoor weathering box.

( Source : Courtesy of Atlas Material Testing Technology LLC.)

The use of plastics in increasingly demanding applications has created a need for developing tests that simulate real‐life applications. The traditional method of comparing properties of plastics and rating one material against another is no longer adequate since the results do not reflect the behavior of the product in real‐life situations. Laboratories are focusing on testing products under special circumstances and conditions. New regulations have spurred auto manufacturers and suppliers to test and characterize the energy‐absorbing properties of the materials used in instrument panels and other components that drivers and passengers may come in contact with in the event of an accident. High‐rate impact testers simulate the dynamic nature of a car crash much better than traditional impact tests. To simulate the conditions found in the interior of an automobile, an outdoor weathering box has been developed by a leading material testing company. This under‐glass exposure cabinet was primarily designed to accommodate nonstandard specimen sizes such as complete automotive assemblies as well as standard ten × 15‐mm samples. Various types of windshield or side window glass can be installed for evaluating the effects of different types of glass on automotive interior components. Color and gloss measurements and visual inspections are performed at intervals according to applicable test standards. Figure 1‐5 a illustrates one such box capable of housing a variety of components, including headphones, remote control devices, CD covers, and window tinting films. Figure 1‐5 b shows an instrument panel exposed in a box designed to simulate an automobile interior.

A new type of test methodology for characterizing engineering plastics has been developed. These techniques simulate the extrusion and molding process to show what a polymer would undergo in terms of shear, temperature, pressure, and residence‐time deformation. The behavior of a compound can be accurately predicted before processing. An online‐type rheometer continuously measures the viscosity of the polymer from the die on a real‐time basis, and the data is used to make a screw speed adjustment to keep the viscosity consistent (9).

1 1. Lamond, L., “Right Perspective on Test Data Matches Material to Application Criteria,” Plastics Design and Processing (March 1976), pp. 6–10.

2 2. “A Guide to Standard Physical Test for Plastics,” DuPont Tech. Rept. No. TR 91.

3 3. Schmitz, J. V. (Ed.), Testing of Polymers, Interscience, New York, 1965, p. 3.

4 4. Ibid, p. 4.

5 5. Ibid, p. 22.

6 6. Zwick USA, 1620 Cobb International Blvd., Kennesaw, GA 30152.

7 7. Datapoint Labs., 95 Brown Road., Ithaca, NY 14850.

8 8. Sherman, L. M., “Impact: Which Test to Use? Which Instrument to Buy?” Plastics Technology online, www.plasticstechnology.com/articles/200110fal.html

9 9. Stewart, R., “Plastics Testing,” Plastics Engineering (June 2003), pp. 20–28.

Конец ознакомительного фрагмента.

Текст предоставлен ООО «ЛитРес».

Прочитайте эту книгу целиком, купив полную легальную версию на ЛитРес.

Безопасно оплатить книгу можно банковской картой Visa, MasterCard, Maestro, со счета мобильного телефона, с платежного терминала, в салоне МТС или Связной, через PayPal, WebMoney, Яндекс.Деньги, QIWI Кошелек, бонусными картами или другим удобным Вам способом.