Another storage technology are flywheels that store kinetic energy and can discharge DC power to a UPS. Conventional batteries and flywheels are covered in more detail in the UPS chapter. Also worth mentioning here are some new battery storage technologies called Zinc‐Bromine Flow Batteries and a megawatt‐class of batteries that use a sodium‐sulfur electrolyte – which are both, by nature, DC sources. Both of these batteries have the potential to be used in grid‐storage class applications and may undergo many deep discharges without suffering ill effects.?? Various battery manufacturers are developing battery storage banks so that excess power produced from solar panels or other renewable sources during the day can be used at night, or other sources like hydropower can charge batteries at night for discharge during peak daytime hours reducing demand loads on fossil fuel plants. For additional information, see Chapter 10– UPS.

As of this writing, sodium‐sulfur batteries have already been installed at several locations globally, including a wind farm in Japan and a bus depot in Garden City, NY. Zinc Bromide batteries have yet to prove themselves in anything more than a handful of demo installations, but the technology seems promising for the storage of electricity from intermittent sources and load‐leveling applications, similar to sodium‐sulfur batteries.

3.11.4 Renewable Energy Integration

Solar power is the most common renewable resource that can be used for the on‐site generation of electrical power for a data center. Since photovoltaic (PV) arrays produce DC electricity, it is easily integrated with a DC distribution system. Only a voltage regulator is required, or a charge controller if the PV array is used to charge battery storage.

Wind power is another option. Inverter‐based wind turbines already produce AC power. The power conversion that would normally be needed to convert the DC to AC is not required, eliminating the inverter and any need for synchronization.

Although technically not a renewable energy source, fuel cells are being used to convert natural gas to electrical power locally at data centers and other sites. The output power is synchronized with the utility service and feeds the data center loads through the same distribution. Multiple units can be paralleled to feed a building. Some advantages are that fuel cells are very efficient and will continue providing base power at night when solar panels cannot, or winds die down, and wind power is not fruitful. Another advantage is that excess heat is produced in the conversion cycle that can be used for heating or hot water in the building or used to feed an absorption chiller. Several cons include a natural gas service of sufficient size is required at the site or a tank farm with liquid propane, or other hydrogen‐rich fuel is needed, they are relatively heavy and need to be located outdoors or in a remote structure.

3.11.5 DC and Combined Cooling, Heat & Power

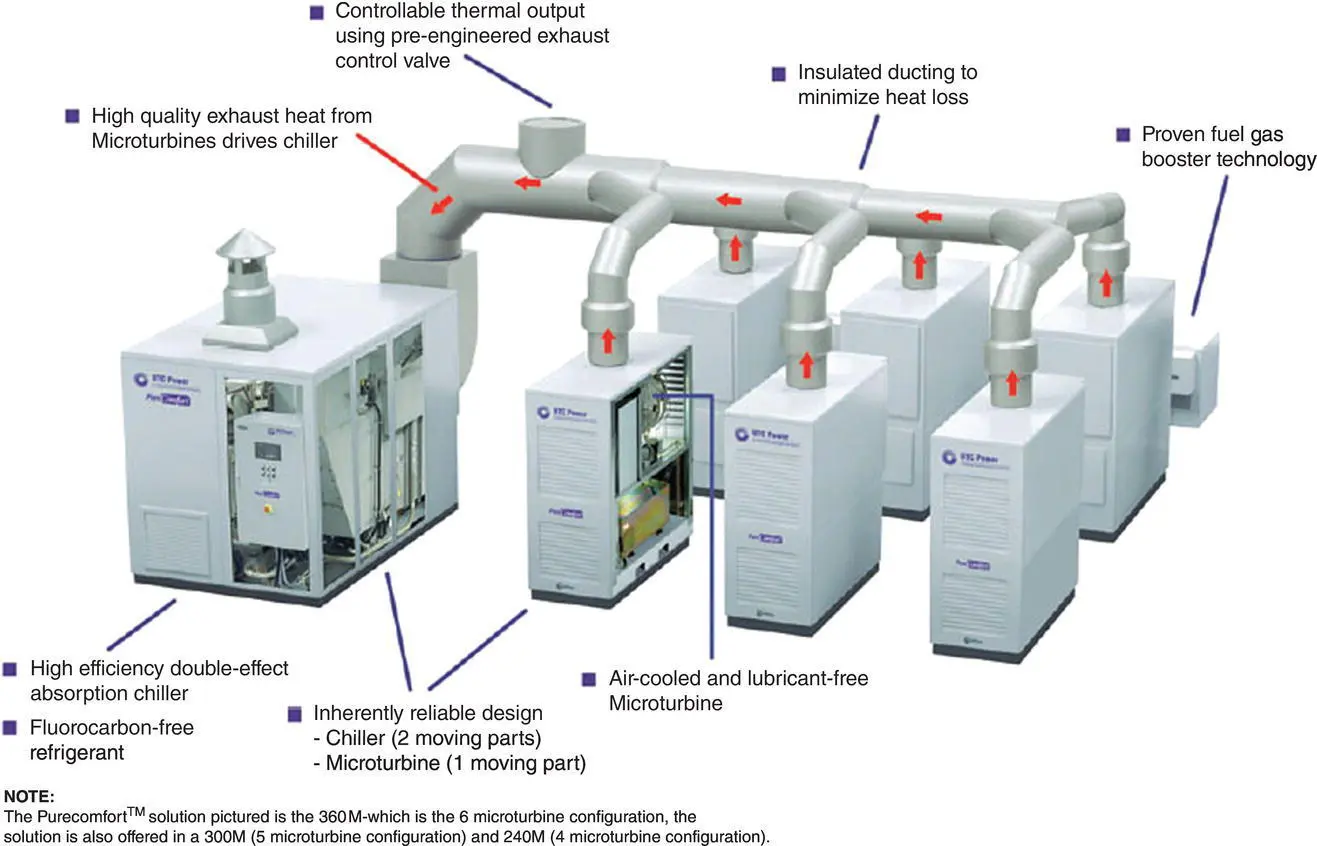

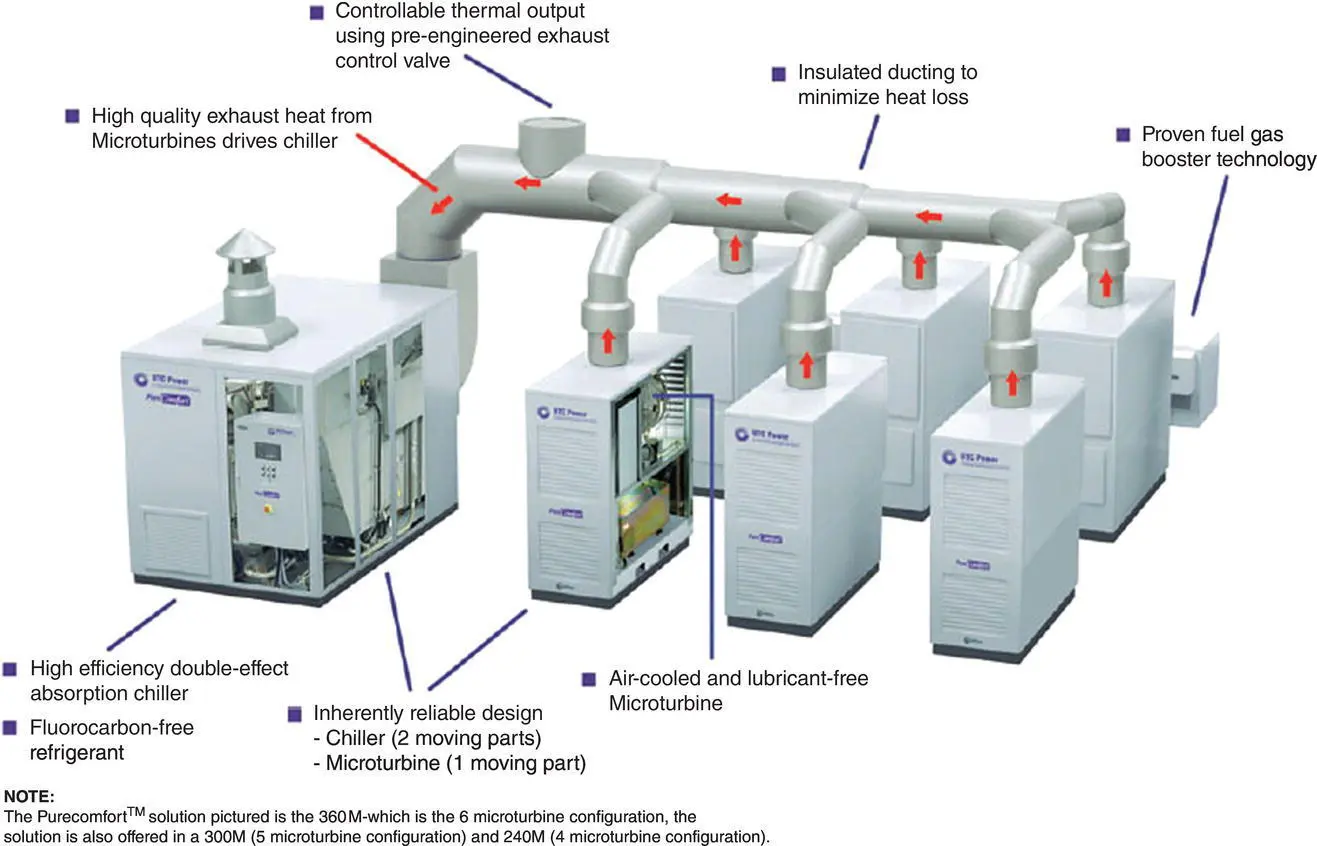

Combined Cooling, Heat & Power (CCHP), also known as cogeneration, is an ideal strategy for improving data center energy efficiency. This is accomplished by using some form of power generation equipment that also produces thermal energy as a by‐product. Since data centers typically require 24x7 cooling, the recovered thermal energy can be used to activate absorption chillers that turn the waste heat into free cooling.

There are two types of power generating equipment that can be easily integrated with a DC distribution system. One is a fuel cell. The fuel cell is an electrochemical device that produces DC electricity, much like a battery. Only a voltage regulator is needed to match the DC voltage of the fuel cell to the DC distribution voltage or an inverter to create AC power that can be synced to a building’s electrical supply or used independently. Since the chemical reaction within the fuel cell produces heat, this thermal energy can be recovered and used to drive an absorption chiller.

Figure 3.7Absorption Chiller

(Courtesy of Yazaki Energy Systems, Inc.)

Figure 3.8Typical Fuel Cell

(Courtesy UTC Power)

The microturbine is another prime mover that can produce DC power. Microturbines operate on the Brayton cycle to rotate a small permanent magnet alternator at very high rpm to generate high‐frequency AC, which is rectified to DC. A voltage regulator can be used to match this DC to the DC distribution voltage, or an inverter can convert the DC power to 60hz AC. The turbine exhaust can be run through a heat recovery absorption chiller to make chilled water.

Figure 3.9Microturbine CCHP System

(Courtesy UTC Power)

One of the first steps in accomplishing the paradigm shift to DC is developing some consensus as to what DC voltage level is best for distribution, given the need to keep current levels and conductor ampacity within reason. The schools of thought range from 48 to 550VDC. These voltage levels that are under consideration fall under the National Electrical Code, ANSI/NFPA 70, which defines low voltage as any voltage up to 600 V. The grounding of DC systems is also covered in the NEC in section 250‐3 and 250‐22. Once the preferred voltage level is established, more specific codes and standards will have to be developed. Codes and Standards development is in progress overseas. The European Standard ETSI EN 300 132‐3 v 1.2.1 (2003‐08) covers DC systems up to 400V.

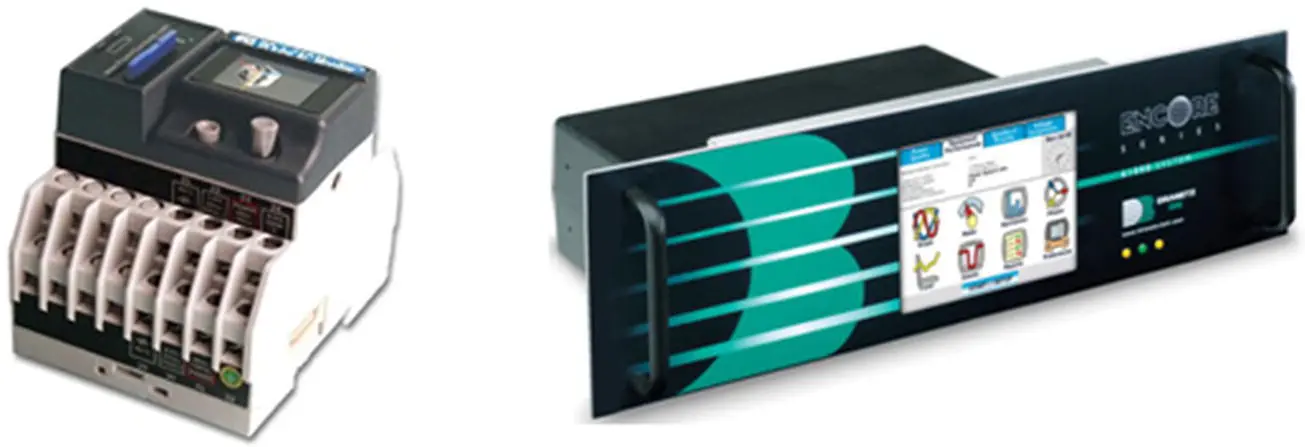

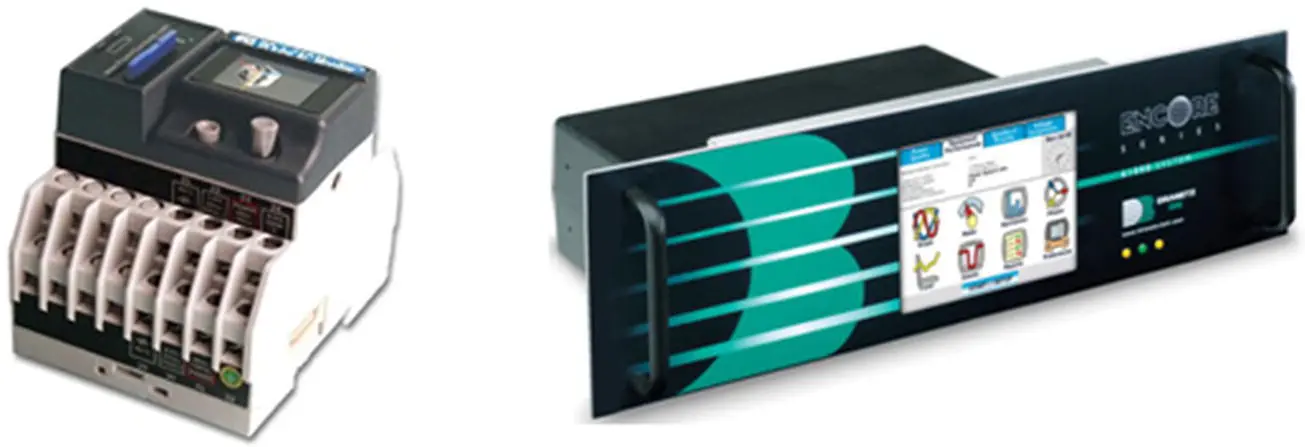

One of the most valuable data center maintenance tools is the Power Quality Monitor. While the monitoring of AC power quality has been done for many years, doing the same thing on DC distribution systems will require different equipment. Fortunately, there are already some instruments available that are up to the task like the PSL PQube® AC/DC Power Monitor and the Dranetz. See Chapter 9– Power Quality for additional information.

Figure 3.10DC Monitoring Equipment

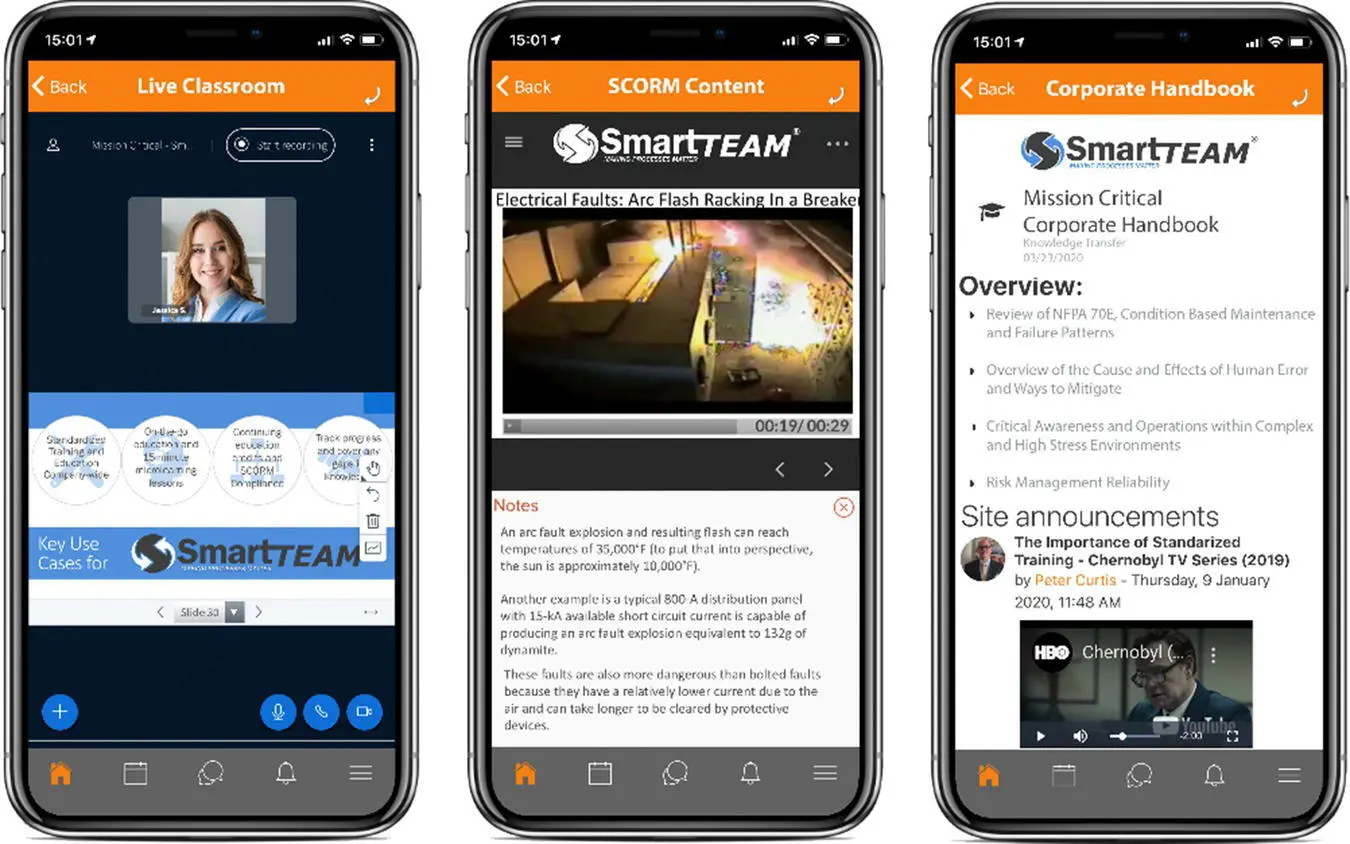

3.11.8 Education & Training

Initially, there may be some difficulty in locating personnel with the appropriate experience to install and maintain these DC systems. With some aggressive training programs, existing personnel will develop the necessary skills. This is the same training and education that is currently underway for the photovoltaic industry, where electrical distribution systems rated up to 600VDC are key ingredients. It should also be noted that there will remain a need for AC expertise, since data center HVAC systems will no doubt continue to be powered by AC, and consequently still need the conventional AC distribution.

Figure 3.11Smart TEAM ™ mobile screenshot

Читать дальше