Furthermore, the control architecture of the mechatronic system could use either decentralized control systems, DCSs, hybrid control systems, monitoring and control systems, fault-tolerant control systems, and embedded control systems. Hence, some of them are expected to require remote and synchronization tools through data transmission and acquisition tools to ensure the coordination between operating entities as well between mechatronic system components. Recalling that any mechatronic system is by its design a combination of electrical, mechanical, and information processing technology, the control solution of a mechatronic system could combine: (i) built-in intelligence; (ii) real-time programming; and (iii) multifunctional operating characteristics. For example, this could result in higher service productivity, quality, and reliability (e.g. reduced failure rate), by embedding intelligent, self-correcting sensory feedback systems. Thus an integrated approach is suitable for the control of any multi-functional mechatronic system.

Regarding mechatronic systems and processes, three main types of integrating control design strategy can be considered: (i) spatial and structural integration; (ii) functional integration; and (iii) performance-based integration. Here, this textbook focuses on control design integration related to information processing (i.e. advanced control function along with monitoring and diagnostic features). As such, in order to achieve an efficient controlled mechatronic system, any control design project steps must encompass a coherent synergy of selection and design effort between a mechatronic system and process components (actuating, sensing and data acquisition, control systems, and computing unit) under technically complex operating requirements. A project related to control system design or migration has either:

1 time-based objectives, such as improving service or productivity through an enhancement of mechatronic system functions;

2 cost-based objectives, such as reducing the cost of system operation (e.g. energy reduction) or service by improving the performance of the controlled mechatronic systems;

3 quality-based objectives, such as improving system operations efficiency or service reliability through the enhancement of control functions for mechatronic systems;

4 a combination of control system design objectives, such as delivering new services or products, replacing or extending them; or

5 monitoring and analysis objectives to be integrated into the mechanism system design.

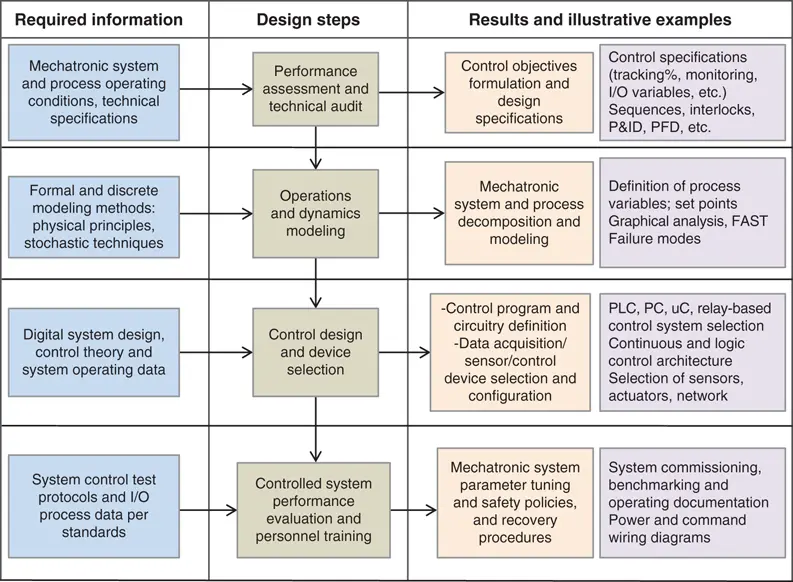

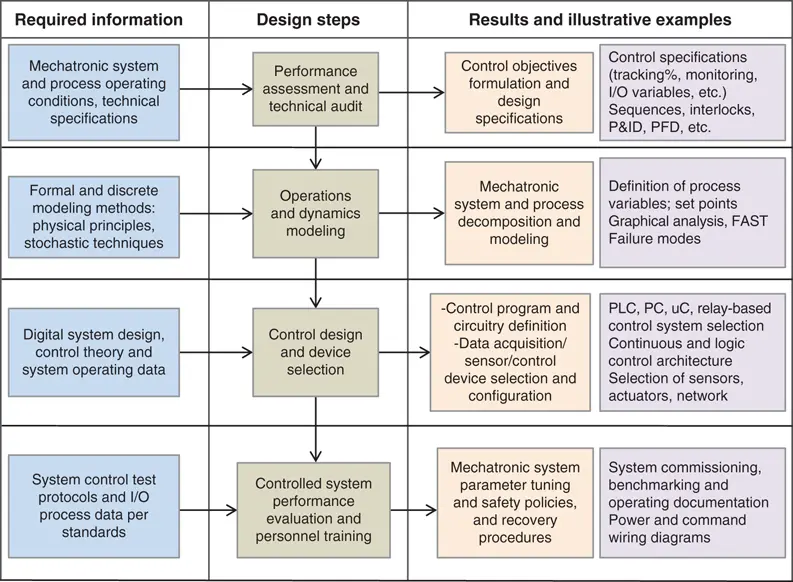

To fulfill these objectives, the major project steps in control system design are:

1 Preliminary studies based on mechatronic system and process schematics.

2 Performance technical audit:performance assessment;performance objectives and controller specifications.

3 Functional analysis and modeling:FAST decomposition method;operating conditions and discrete time modeling;startup and shutdown sequence relationship diagram;operating description and discrete event formal modeling.

4 Hybrid controller and digital system design:continuous controller algorithm;logic controller software design;storage requirement assessment (memory size etc.), control system throughput, user interface requirements;controller hardware design (control panel design and layout, instrumentation system design and layout);logic controller circuitry design (distribution and control architecture).

5 Controller solution execution and commissioning:control feedback variable tuning;operation monitoring under failure modes;operation validation based on control system test protocol;personnel training;deployment.

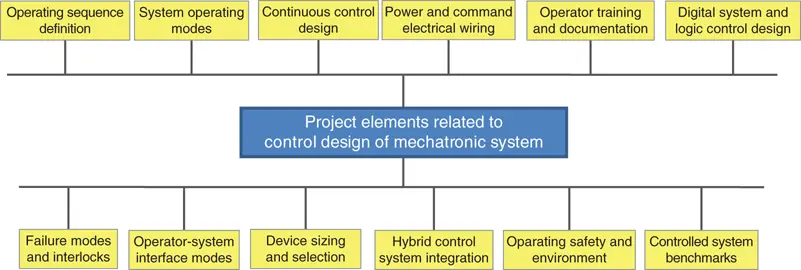

Those steps could be summarized as shown in Figure 1.12. Activities related to control design or migration projects are expected to provide specific mechatronic system control documentation such as:

1 Mechatronic system and process diagrams, especially:process flow (PF) and piping and instrumentation (P&I) drawings based on the mechatronic system description, if possible;cabling and wiring diagrams (power distribution schemes, data cable routing and cable diagrams, instrument hook-up drawings);electrical schematics and connection diagrams connecting operator user interface actuators and sensors through a detailed panel layout;power supply, interconnection, and distribution diagrams, and electrical device placements, such as the number of repeaters between nodes;field control instrument lists with data sheet formulation for various instruments such as: flow, level, pressure, differential pressure, temperature, transmitters, converters, isolators; multipliers; control valves and so on; anddiagrams for safety compliance (interlock schematics).

2 Documents for mechatronic device sizing and selection, especially on:actuating elements such as motor drives, control valves, orifices with estimates (calculations) of their operating conditions;sensing elements such as piezoelectric flow sensors;data processing and computing elements (memory size, scan cycle etc.); andpower storage and utilities equipment, such as uninterruptible power source (UPS) batteries (capacity etc.).

3 Documents on sizing and selection of data network components (type, media etc.) and replacements especially related to:selection of I/O modules (integrated/distributed);I/O addressing;data logging and process data archiving; anddatabase structure formulation.

4 Documents on hybrid controller structure, configuration, and operation:continuous control and logic control design algorithm and digital system circuitry; andcontrol system configuration and instrument calibration.

5 Control system maintenance/support procedures and documents including:I/O process interface for discrete and analog fields devices as well as memory organization;detection and diagnosis of external field control device failure, I/O module replacement procedure; I/O process wiring check, operational testing (factory acceptance testing), definition of emergency stops, and safety control relays;power supply, controller memory card replacement procedures; andtroubleshooting procedure and listing of hybrid control software errors.

Figure 1.12 Generic controller design steps and dependencies.

Source: Adapted from Kaltjob P.

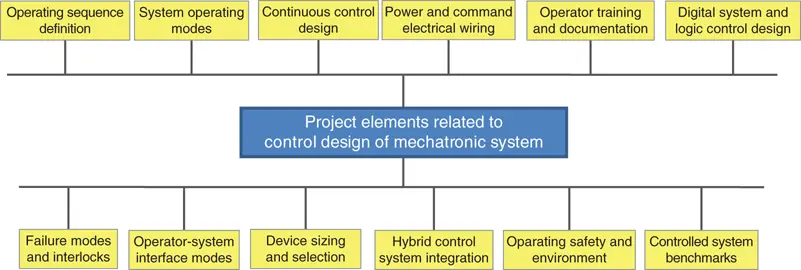

Figure 1.12summarizes the major steps and documents required in process control as well as those expected to be provided, while Figure 1.13presents activities in a design control project for a mechatronic system.

Figure 1.13 Overview of activities related to control project management.

Source: Adapted from Kaltjob P.

1 1.1 Insulin is a pancreas-generated hormone that regulates blood glucose concentration. A diabetic patient has the inability to produce a significant blood level of insulin. He has to rely on an artificial pancreas as a mechatronic device to regulate the blood glucose level by providing automatic insulin injections several times per day. Based on the patient's diet or physical and psychological activities, the amount of insulin necessary to maintain a normal blood glucose level must be determined.Identify the control functions for this mechatronic system for the regulation of blood glucose level and list all input and output system variables.Briefly describe the possible hybrid control strategy for this mechatronic system for the regulation of blood glucose level and list the control variables.Build a block diagram with the hybrid control system of blood glucose level using a real-time blood glucose measurement device and a continuous insulin infusion pump.Sketch a logic control connections of this mechatronic system instrumentation (hybrid control with control panel).

Читать дальше