In both instances, the effect of the catalyst was thus indirectly considered by measuring the reaction kinetics and introducing their defining parameters in the simulation set‐up. The approximation of introducing the modified reaction kinetics in a porous bed is thus a well‐established trend in the literature, which can yield valuable insight into how a particular catalyst affects the development of a carbon conversion reaction.

Other numerical techniques might be useful for the numerical study of the methanation reaction in other types of reactors. In those cases where the methanation reaction occurs in a fluidized bed of catalytic powder, the Euler–Euler method and the more computationally expensive CFD‐DEM approach can be applied. Liu et al. for instance implemented the methanation reaction of carbon monoxide plus the water shift reaction in an Euler–Euler model of a fluidized bed using the solver twoPhaseEulerFoam , within the open‐source CFD library OpenFOAM. The main code was modified to accommodate the kinetic model proposed by Kopyscinski et al. [62]. The effect of feed composition and the catalyst inventory on the concentration profiles across the fluidized bed were obtained and compared to the experimental data of Kopyscinski et al. [63] showing fair agreement. Another instance of the application of the Euler–Euler method to the study of the methanation reaction was presented by Sun et al. [64], who used the specific purpose software MFIX to study the methanation reaction of carbon monoxide in a fluidized bed using the Euler–Euler approach. The effect of operating parameters and catalyst inventory are investigated and the reactor will get eventually optimized. An example of the use of the coupled CFD‐DEM model to analyze the hydrodynamics within a methanation fluidized bed reactor was presented by Wu and Tian [65]. DEM provides further insight as a result of the assessment of the behavior of single solid particles within the bed at the expense of a substantially increased computational time.

2.7 CFD for Biological Utilization: Microalgae Cultivation

As for the application of CFD to biological utilization of carbon dioxide for photosynthetic production of microalgae, the number of published studies is rather limited. One of the most recent and representative studies available is the work reported by Chatterjee [66]. This article is concerned with the internal hydrodynamics of a photo‐bioreactor (PBR) but ignores any other aspects such as the chemistry of the system or the distribution of light across the vessel, which is crucial to the efficiency of the process and depends on the shape of the PBR. Another assumption in this model is that the mass and weight of the microalgae formed in the process were neglected.

Chatterjee [66] carried out a comparative study between a bubble column reactor and a serpentine PBR configuration using ANSYS CFX‐14.0 (Euler–Euler multiphase approach) with time steps ranging from 0.1 to 2 seconds and grids with a number of nodes varying between 75k and 109k. The modeler needs to have special care with the development of the mesh, which must have an appropriate resolution relative to the size of the gas bubbles formed within the PBR. The other crucial aspect is the choice of the turbulence model. Given that the scope of this work is to assess the mixing parameters, the turbulent model must be selected carefully. Both the standard k – ε model and the Reynolds stress model (RSM) were tested. The latter option resulted in a better match between the CFD and the experimental data in terms of gas hold‐up and gas velocities throughout the reactor. The set‐up gave way to valuable maps of turbulence kinetic energy, velocity swirling strength, and gas hold‐up within the domain. The results show that the serpentine configuration gives way to more intense turbulence, which in turn should theoretically result in better microalgae growth rate.

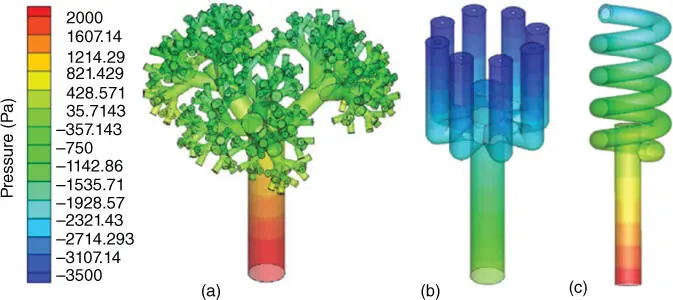

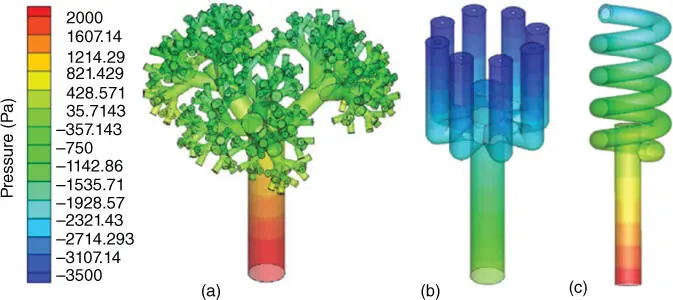

Perhaps the most innovative CFD work concerning PBRs is, however, the article presented by Zhang et al. (2019), who carried out a CFD study of a bionic fractal‐inspired branch‐like PBR. Fractal shapes are the solution provided by Nature for those applications where a high area‐to‐volume ratio is required. They used a similar set‐up to that presented by Chatterjee [66], based on the Euler–Euler method for gas–liquid interface tracking combined with the k – ε turbulence model in order to compare the performance of fractal‐inspired branched geometries to that of common configurations such as multi‐tubular and serpentine. As for the spatial discretization, finer meshes were employed because of the tiny spaces formed in the successive branching generations of the fractal shape (5 thbranching generation with diameters in the order of the millimeter). A grid independence study was conducted using three non‐structured meshes (a coarse mesh with 1.30 m nodes, a medium mesh with 2.48 m nodes, and a fine one composed of 3.5 m nodes). The prospective user can thus have an approximation of the degree of grid refinement required in these simulations given the diameter of the channels and the number of nodes, which need substantial computational resources. The results of their model suggested that better mixing occurs when using the fractal shape relative to the multi‐tubular and serpentine configurations, together with small pressure drops ( Figure 2.6).

The literature confirms thus, CFD modeling as a valuable tool to carry out preliminary proof of concept of innovative PBR shapes. An interesting proposal for further work would be, however, to use a multispecies approach including mass source terms to account for the consumption of carbon dioxide and the growth of microalgae.

2.8 What Does the Future Hold?

As presented previously, CFD modeling has proved a beneficial tool for the modeling of CCSU technologies, thus helping to get insight into problems where experimental measurements cannot be obtained or analytical solutions are impossible. Process simulations on the other hand are used in order to provide information for the design and operation of entire plants. Both CFD and process simulations have their advantages and disadvantages when applied separately, but the combination of both techniques to run in parallel and live feedback each other would offer new opportunities to analyze and optimize the overall plant performance.

Figure 2.6Pressure maps within PBR reactors obtained using CFD simulations to shed light on the pressure distribution of three geometric configurations: (a) fractal‐inspired shape, (b) multi‐tubular, and (c) serpentine.

Source: Adapted from Tao et al. (2019).

There have been several efforts in different fields of engineering to integrate CFD and process simulations. Proof of this is the recent development a co‐simulation software framework at the DOE National Energy Technology Laboratory in the United States, which was applied to fossil energy systems with carbon capture. This tool is called APECS (advanced process engineering co‐simulator) and allows the design and optimization of the overall plant performance based on detailed high‐fidelity fluid dynamic models (CFD). Other instances of co‐simulation strategies applied to CCSU technologies are the work of Zitney [67], where an integrated gasification combined cycle (IGCC) power and hydrogen coproduction plant with carbon capture was analyzed by feeding data from CFD models into Aspen Plus. The results of the integration showed that the overall plant performance is affected by complex thermal and fluid flow phenomena that can only be analyzed at the CFD level; otherwise, process simulations miss those details. Another example of the intertwining between CFD and process simulations can be found in the work of Fei et al. [55], where the link between CFD and process simulations was accomplished by developing reduced order models (ROM) with the CFD data and introducing them into the process model. Edge et al. [54] on the other hand obtained temperature contours, velocities, and mole fraction maps of different species involved by using CFD and introduced the data into the process simulation tool gPROMS to assess the retrofitting of a coal‐fired power plant into an oxy‐fuel plant. Their approach resulted in guidelines as for the conditions where the system results in the same efficiency as air‐firing. Also, similar to Fei et al. [55], Lang et al. [68] presented a co‐simulation approach for an IGCC by developing an ROM via CFD in order to reduce the computational time and then optimize the plant by using process simulations. The efficiency of the process was increased by 7%, compared to the conventional configuration.

Читать дальше