Table 3.10 Lag time (the time that the coating was on the nail), steady-state flux, permeability coefficient, diffusion coefficient and amount of drug in nail clippings.

| Formulation |

Lag time (day) |

Steady-state flux (μg/cm2/day) |

Permeability coefficient × 10-5 (cm/day) |

Diffusion coefficient × 10-5 (cm2/day) |

Drug in nail clipping (μg/cm2) |

| Curanail film (32 wt.% Amorolfine HCl) |

10.4 ± 1.3 |

2.9 ± 0. 2 |

5.8 ± 0.3 |

2.5 ± 0.5 |

61.1 ± 14.8 |

| 3 wt.% Amorolfine HCl UV-cured film |

10.4 ± 0.9 |

2.4 ± 0.2 |

7.9 ± 0.7 |

2.7 ± 0.8 |

37.5 ± 17.6 |

| 4 wt.% Terbinafine HCl UV-cured film |

9.5 ± 1.2 |

1.5 ± 0.1 |

3.7 ± 0.3 |

1.6 ± 0.4 |

71.1 ± 8.0 |

| Statistical difference between Curanail and Amorolfine UV-cured film? |

No ( p >0.05) |

Yes ( p <0.05) |

Yes ( p <0.05) |

No ( p >0.05) |

Yes ( p <0.05) |

| Statistical difference between Amorolfine and Terbinafine UV-cured film? |

No ( p >0.05) |

Yes ( p <0.05) |

Yes ( p <0.05) |

Yes ( p <0.05) |

Yes ( p <0.05) |

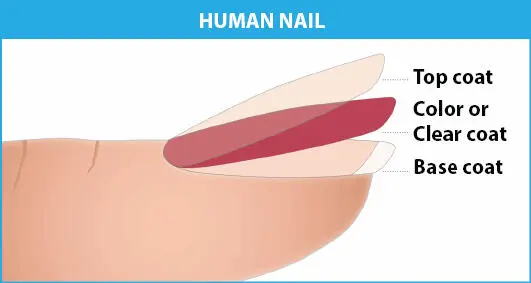

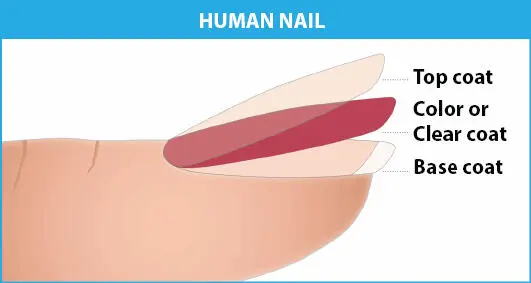

Figure 3.19 UV nail gel construction: Human nail, UV nail gel base coat which is used primarily to obtain adhesion to the human nail and to even out irregularities of the surface, UV nail gel color coat or clear coat that can result in multiple shades or clear to show the natural color of the nail, and UV nail gel top coat that ultimately results in the performance layer of the nail.

3.12 UV-Cured Nail Gel Safety

As one can see in Figure 3.19the UV nail gel technology is applied to the human nail in built-up layers. The base coat is primarily used to obtain adhesion to the human nail and to even out irregularities of the nail surface. The next layer (intermediate coat) is the color coat that can result in multiple number of shades. However, this layer (intermediate coat) can be used without pigmentation which results in a clear coat that exhibits the natural color of the nail. The final layer is the top coat and this ultimately is the performance layer of the nail. Concerns for safety of the UV nail gel technology can be seen in two specific areas; 1) the UV cure light exposure, and 2) acrylated oligomers, acrylated monomers and PIs used in the formulation of the UV nail gel technology. From the standpoint of the UV cure light technology a study [27] showed that the worst-case scenario was exposure to UV-A light source for 36 minutes per day which was far below the occupational exposure limits for UV radiation. The report showed that normal use of a UV nail gel lamp only exposed the consumer to 0.5% to 2.2% of the monthly allowable exposure limit to UV energy. These energy levels were 0.30 to 1.676 µW/cm 2. The UV cure light units operated within the UV-A range of 350 to 400nm [27]. The formulation of the UV nail gel as shown in the previous section contains (meth) acrylate monomers. A recent study [28] found concerns with allergic contact dermatitis (ACD) due to the use of (meth) acrylate monomers in the nail gel formulations. They found that 241 patients tested over a three-year period had a positive patch reaction to the acrylate resin. In light of some of these ACD issues, the British Contact Dermatitis standard series of concerned chemicals has just added 2-hydroxyethyl methacrylate to this series. In addition, the studies found that both local and distant ACD can occur that would result in hyperkeratosis and fissuring of the finger pulp, lichenoid or psoriasiform eruptions, paronychia and nail dystrophy. Concerns were also shown that evaporation of the nail gel results in airborne ACD that could result in issues for the face, neck and ears [28].

3.13 Prospects on UV Nail Gels

Nail polishes were used in the US by 117 million Americans in 2016 and is expected to reach 122 million by the end of 2020 [17]. The global UV nail gel market is expected to be worth $59.31M in 2020 with a CAGR of 6.5% according to Markets and Markets research firm. North America accounted for 53% of the global market as of 2014. Methacrylated oligomers and methacrylated monomers account for 95% market share with 5% for the acrylated oligomers and acrylated monomers [1].

With the UV cure nail gel industry having its roots in the dental industry of the 1950s through the 1970s, this technology became successful in the late 1990s [29]. At the same time the industrial UV cure coatings market was also developing low energy cure technology for the automotive and aerospace industries. This forced the suppliers of the oligomers, monomers, photoinitiators and UV light sources to invest in developing technology that would cure with low level UV-A light sources. The biggest issue that the technology faced was oxygen inhibition. It is interesting to note that the industrial and nail gel markets both benefited from these new developments. With UV light sources transitioning from GA-FL to the LED, the technologies for both markets have taken a significant leap.

Today’s UV nail gel market will continue to grow and has some unique potential for delivering anti-onychomycotic drugs for the elimination of toenail fungus in the toenail plate.

However, concerns over the industrial hygiene issues for the chemistries being used will continue to plague this growing market for the consumer and the UV nail gel technician. In addition, there are industrial hygiene concerns with the UV light sources that cure the UV nail gel whether it is from the FL-GA or LED UV units.

The UV nail gel technology has its roots in the UV cure dental restoration and industrial coatings application areas. The uniqueness of the UV chemistry allows the UV nail gel product the ability to cure the UV nail gel products in minutes vs hours for the conventional nail polish lacquer. In addition, the crosslinking of the UV nail gel results in a coating that will last multiple weeks vs. days for the traditional nail polish lacquer. UV cure light sources have evolved since the introduction of the UV nail gel product that used the GA-FL units which are now being displaced with the newer UV LED technology. Oligomeric, monomeric and PI technology also needed to be developed that was able to override the oxygen inhibition and the use of pigmentation for the UV nail gel technology. Initial introduction of UV nail gel technology was centered around the 100% solids oligomer and monomer technology but has now seen newer introductions of water-based UV cure polyurethane dispersions. In addition, bio-based UV nail gel technology has seen introduction of 100% solids and UV cure polyurethane dispersions.

As with any coating’s technology, the UV nail gel technology also needed to understand surface free energy, adhesion, mechanical properties and removal techniques. Alternative use for the UV nail gel technology is as a solution to remedy toe-nail fungus.UV cured nail gel safety has also become an issue. Testing of the UV cure light sources, oligomers, monomers, PIs and removal techniques of the cured coating have been investigated and continue to be investigated especially as newer products are introduced.

The UV cured nail gel technology is unique and has seen a rapid growth in the nail polish marketplace.

Читать дальше