Corrosion Policy Decision Making

Здесь есть возможность читать онлайн «Corrosion Policy Decision Making» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Corrosion Policy Decision Making

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:4 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 80

- 1

- 2

- 3

- 4

- 5

Corrosion Policy Decision Making: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Corrosion Policy Decision Making»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Explore the science, management, economy, ecology, and engineering of corrosion management and prevention Corrosion Policy Decision Making

Corrosion Policy Decision Making

Corrosion Policy Decision Making — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Corrosion Policy Decision Making», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

Inadequate regulation of paint viscosity and spraying pressure in airless spraying, as well as inadequate air‐to‐paint ratio in air spraying methods are other causes of complications during application. These factors lead to difficulty in achieving the right thickness as well as complications such as sagging and running, etc.

2.2.5.9 Inspection and Management

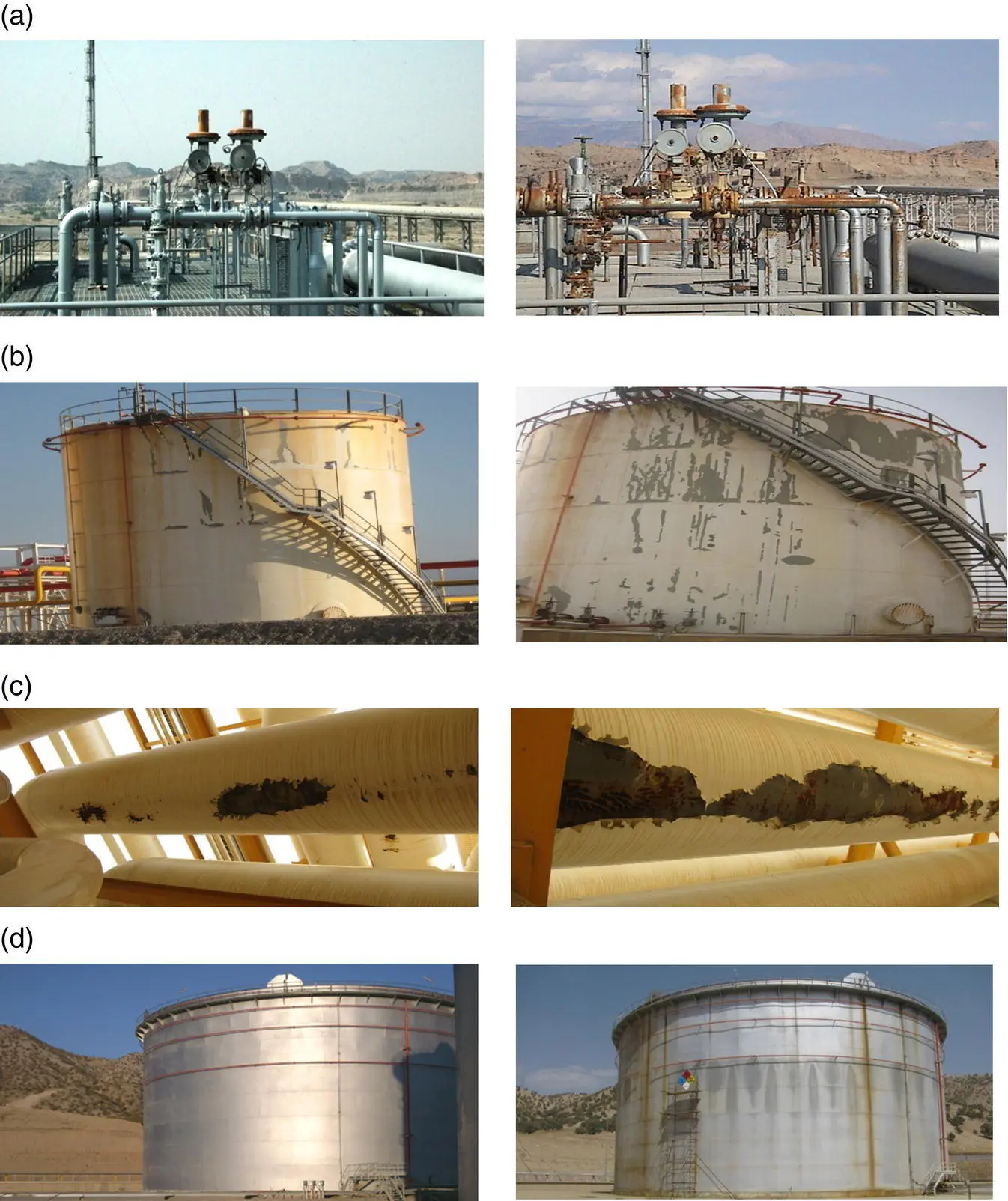

Industrial paint inspection plays an important role in the useful life of paints and paint systems. Unfortunately, in certain circumstances, surface preparation and paint application is performed without the necessary care by inspectors. For example, for problems referred to in Figure 2.18, the paint was applied only on visible sections. In addition, the primer was applied to the previous existing paint, which is another gross mistake of inspection.

On the other hand, a number of refinery project managers have no technical approach to the issue of paints and some of them consider it as one of the last priorities. Unfortunately, sometimes the project manager tries to compensate for the delay in completing the project by reducing the surface preparation and paint application time, and orders for increasing the speed of the paint operations.

Paint is very important as the most common way to prevent corrosion. It also gives beauty to the facilities and will give the workers a sense of security and safety while doing their work. Lack of attention to the problems of paint leads to the rapid development of damage, especially in chemical and marine facilities that are more likely to exhibit paint problems. See some examples in Figure 2.19. In this comparison, the intervals of periodic visits were only two years.

Figure 2.18 Weak inspection and management.

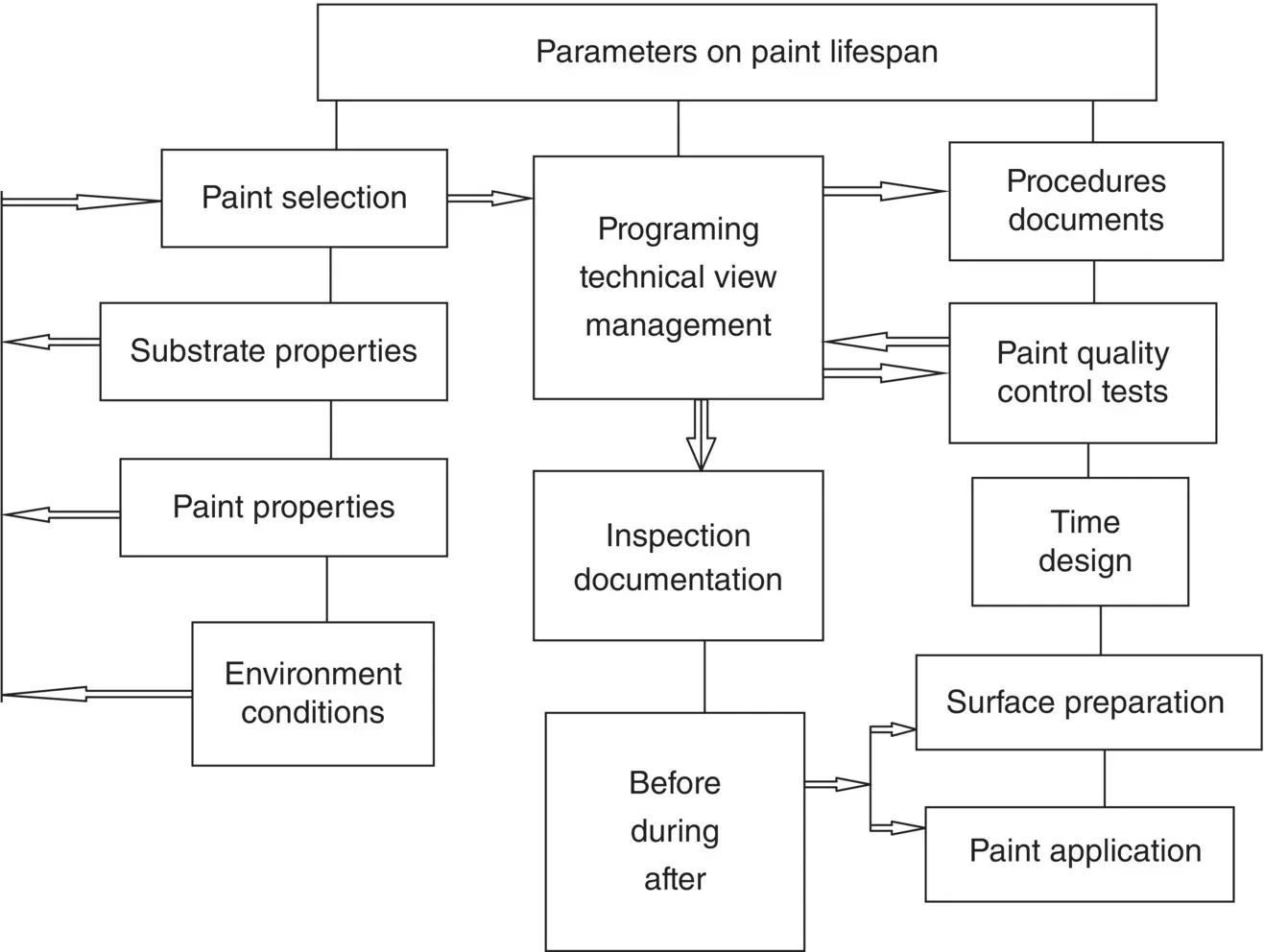

Full documentation of the operation inspection can significantly reduce paint defects during the service life of the equipment. These documents show compliance with the standards. They show precision at choosing the right paint systems, performing the correct surface preparation, and good application. So, attention paid to proper instructions for the items listed in Figure 2.20is essential.

Figure 2.19 Rapid development of damage, especially in chemical and marine facilities that are more likely to exhibit paint problems. Defects developed during two years. Documented at May 2009 (left). Documented at October 2011 (right).

Figure 2.20 Effective parameters on paint useful lifespan.

2.3 Conclusion

Science of corrosion is based on understanding three main elements: what metal liberates electrons (thus becomes an anode and is consumed), which material takes electron (and becomes a cathode), and what fluid ions can move through easily. It follows, then, anything that can interrupt one or all of these elements is highly likely to affect corrosion and control it. If, for example, paint (more correctively, coating) is applied, then anode and cathode will not see each other or anode–cathode will be isolated from the external electrolyte; the former will not allow electron transfer and the latter will not allow ion exchange.

In this chapter, three main methods for corrosion prediction (SHE, Galvanic series, and Pourbaix doagrams) as well as categorizing five technical managements of corrosion have been briefly explained. In addition to a short description of each of the five categories, a rather detailed explanation about materials selection and paints has been given to allow the readers a feeling of some of the difficulties involved in technical treatment strategies to deal with corrosion.

References

1 1 https://agmetalminer.com/metal‐prices, last visited 2 January 2021.

2 2 Javaherdashti, R. and Akvan, F. (2020). Failure Modes, Effects and Causes of Microbiologically Influenced Corrosion: Advanced Perspectives and Analysis. Elsevier.

3 3 Javaherdashti, R. and Akvan, F. (2017). Hydrostatic Testing, Corrosion, and Microbiologically Influenced Corrosion: A Field Manual for Control and Prevention. Boca Raton, Florida: CRC Press.

4 4 Javaherdashti, R. and Nikraz, H. (2010). A Global Warning on Corrosions and Environment: A New Look at Existing Technical and Managerial Strategies and Tactics. VDM Germany.

5 5 Javaherdashti, R. and Alasvand, K. (2019). Biological Treatment of Microbial Corrosion. Elsevier.

6 6 Javaherdashti, R. (2015). Corrosion and Biofilm. In: Biofilm and Materials Science (eds. H. Kanematsu and D. Barry), 79–83. Springer.

7 7 Munger, C.G. and Vincent, L.D. (2014). Corrosion Protection by Protective Coatings. Houston, TX: NACE International ISBN: 575902621 9781575902623.

8 8 Schweitzer, P.A. (2007). Fundamental of metallic corrosion: Atmospheric media corrosion of metals. CRC Press – Taylor & Francis.

9 9 Přikryl, R., Smith, B.J., and European Geosciences Union. General Assembly; Geological Society of London (2007). Building Stone Decay: From Diagnosis to Conservation, 295. ISBN: 78‐1‐86 239‐218‐2. Geological Society (accessed 26 September 2012).

10 10 Ghanbarzadeh, A., Neshati, J., Bagherzadeh, M.R. et al. (2013). Atmospheric corrosion map of an oil refinery. Anti Corrosion Methods and Materials 60: 106–114.

11 11 ISO 12944‐Part1 to 8, Paints and varnishes – Corrosion protection of steel structures by protective paint systems. ISI standard, 2017.

12 12 BS 5493, Code of practice for Protective coating of iron and steel structures against corrosion (Formerly CP 2008), UDC 624.014.2:691.71:620.197.6, BS Standard, 1977.

13 13 Akbarinezhad, E., Faridi, H.R., and Ghanbarzadeh, A. (2009). Evaluation of zinc rich ethyl silicate primer by applying electrochemical methods. Journal Surface Engineering 25 (2): 163–166.

14 14 Hess, M., Mamburg, H.R., and Morgans, W.M. (1979). Paint Film Defects, Their Courses and Cure, 3e. London: Chapman and Hall ISBN: 47099018X 9780470990186.

15 15 Solverchem (2017). Industrial Paints Formulation Encyclopedia 2. Solverchem Publications Company, ISNN 9786056715730.

16 16 SSPC Painting Manual (2009). Systems and Specifications, Society for Protective Coatings, vol. 2. Pittsburgh, PA: SSPC.

17 17 Bagherzadeh, M.R., Jorsaraie, A., Ghanbarzadeh, A. et al. (2018). Preparation and investigation of anticorrosion performance of water‐based epoxy coating containing nanohybrid of supercritical CO2‐synthesized self‐doped polyaniline – expanded graphite. Journal of Coatings Technology and Research 15: 1–14.

18 18 Akbarinezhad, E., Ebrahimi, M., Sharif, F. et al. (2014). Evaluating protection performance of zinc rich epoxy paints modified with polyaniline and polyaniline‐clay nanocomposite. Progress in Organic Coatings 77 (8): 1299–1308.

19 19 ASTM D4541 – 17 (2017). Standard Test Method for Pull‐Off Strength of Coatings Using Portable Adhesion Testes. West Conshohocken, PA: ASTM International.

20 20 ASTM D2247 – 15 2020 (2020). Standard Practice for Testing Water Resistance of Coatings in 100% Relative Humidity. West Conshohocken, PA: ASTM International.

21 21 ASTM B117 – 19 (2019). Standard Practice for Operating Salt Spray (Fog) Apparatus. West Conshohocken, PA: ASTM International.

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Corrosion Policy Decision Making»

Представляем Вашему вниманию похожие книги на «Corrosion Policy Decision Making» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Corrosion Policy Decision Making» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.