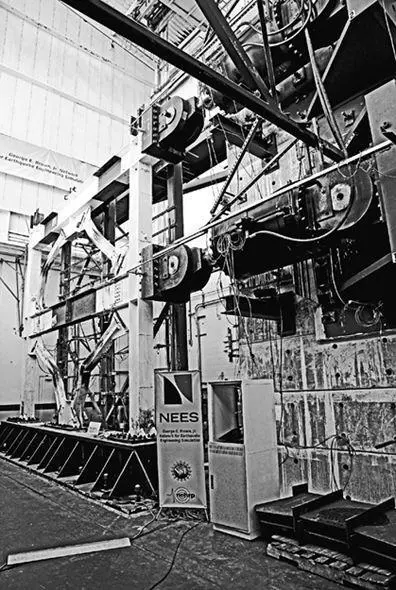

Researchers at the Oregon State University Tsunami Lab have built a model city in the football-field-sized wave tank and use enormous machine-controlled paddles to generate a wave. Simulating a tsunami disaster will help them plan better how to build cities that can withstand flooding. (illustration credit ill.11)

As scientists in these labs struggle with floods and fires and quakes, they are also struggling with a fundamental contradiction at the heart of city design. As the urban planning historian Spiro Kostof explains, cities are the result of ongoing conflicts between centralized planning and organic, grassroots development. To prevent people from dying in quakes and floods, for example, we need rules about how and where developers are allowed to build. But city governments can’t control everything. City dwellers aren’t going to be happy if they don’t have the freedom to change their living spaces and neighborhoods. Not everyone can afford to build homes that are robust against every kind of possible disaster, either. That’s why engineering a disaster-proof city isn’t about magically conjuring damage-proof structures. Instead, it means building urban areas that will kill the smallest number of people possible during a disaster. This is pragmatic optimism at its most literal.

Inside the Apocalypse Lab

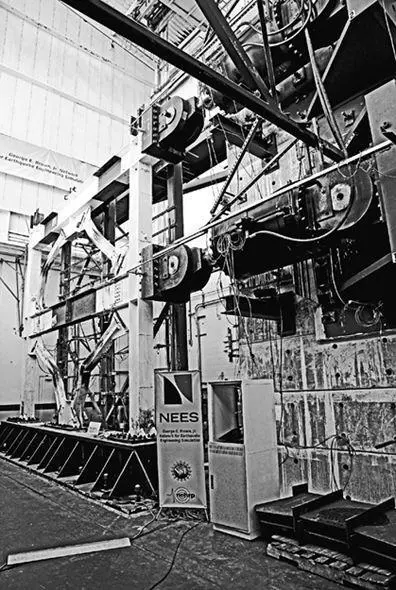

I met the UC Berkeley civil engineer Shakhzod Takhirov inside a three-story warehouse that’s home to UC Berkeley’s Earthquake Simulator Lab. Located in the city of Richmond, the lab is easily identified by its proximity to piles of shattered wood beams, twisted girders, and giant cracked columns of concrete. But this was no junkyard. As I wandered through the rubble, I noticed that every crack and break had been carefully labeled with measurements in permanent marker.

The instruments of destruction that created these piles occupy most of the lab. Towering over my head as I walked in was a 65-foot-tall steel piston that can deliver up to 4 million pounds of compression to whatever structure or material is unlucky enough to be in its grip. Want to simulate traffic load on a bridge support, or the pressures that a skyscraper might deliver to its foundation? This machine can help.

Behind the mega piston, I could see that day’s main experiment. Lab technicians had built a life-sized frame for a single-story building in the middle of the warehouse-sized lab space. Attached to the frame were huge hydraulic motors that looked a bit like pared-down robot arms that were braced between the building and a strong concrete wall. These motors were controlled by researchers in a room packed with computers. With the press of a button, the engineers could deliver small, precise earthquakes to the building—or bone-rattlingly big ones. Sensors on the structure would measure every deformation and shake propagated through it.

Takhirov, who bounced around the control room taking obvious delight in the powerful machines working outside, has always lived with the threat of earthquakes. His birthplace in Uzbekistan is known for its massive quakes, as is the San Francisco Bay Area, where he’s spent much of his adult life. Though he began his career as a mechanical engineer studying wave dynamics, over time he left theory behind and got interested in real-world applications. The day I visited, the researchers were deforming one wall of their building with the motors. The process was slow, involving tiny shifts in the slightly crushed structure, and a great deal of muttering from graduate students about the waveforms we could see undulating across several computer monitors.

In this image from the Earthquake Simulation Lab at the University of California, Berkeley, researchers were experimenting with the performance of steel-frame buildings reinforced with a variety of braces. They tested several braced frames and simulated earthquakes with large hydraulic actuators (the black objects with cylindrical bodies on the right side). Each actuator was capable of applying up to 1.5 million pounds of force. (illustration credit ill.12)

There are two ways to simulate earthquakes. Researchers can use a shaking table, which is exactly what it sounds like. They build a structure on top of a platform that can be shaken from underneath, creating an earthquake, so they can watch what happens and learn from it. The second way is what Takhirov’s colleagues and students were doing. They used their giant actuators to imitate how earthquake forces would deform the building, but they were doing it in slow motion. There was none of the violent motion you would see in an earthquake, but those robot arms carried the same force as a quake would. “Essentially we do this so we can look at each step,” Takhirov said. Using their computers, the researchers can also create a “hybrid simulation” that combines a mathematical model of a building with the physical object they’re manipulating in the lab.

The experiment that I was watching with the one-story building turned out to be a model of a two-story building—the second story existed only in software. We know enough about earthquake engineering at this point that we can actually extrapolate how a second story might behave based on what the first story does when it is slowly crushed by giant motors. Hybrid simulations make it easier for engineers to calculate how city buildings might respond in a quake, even if they aren’t able to build an entire 50-story building and wiggle it.

This particular hybrid simulation would ultimately reveal what happens to a multistory building during a quake if the second floor had been “isolated,” or built with a damper—usually a layer of flexible material—between it and the first story. Isolation stops the quake’s motion from propagating through a building unchecked, preventing it from swaying, torquing, and crumbling. Usually isolators are built into the bases of buildings, but the experiments I saw would demonstrate whether isolation units could be helpful between stories, too. If the isolator prevented significant damage in that simulated second story, these researchers would move on to the next phase of their work—getting their engineering discovery implemented in the real world.

How to Prevent Death with Engineering

What Takhirov and his colleagues learn in the Earthquake Simulator Lab gets translated into the building code, a set of safety rules that constrain how structures are built. These codes exist all over the world, varying slightly from region to region. When engineers like Takhirov make a new discovery about earthquake engineering, their next step is to petition to change the rules that govern city development. “I can conduct several tests, and then I can approach the coding committee with my results and say, ‘I should change things here,’” Takhirov said.

Failure to update building codes is a major reason so many lives are lost in cities during disasters. Takhirov visited Haiti soon after the series of quakes that nearly leveled the capital, Port-au-Prince. He and his team documented the damage, using conventional cameras as well as sophisticated laser-imaging devices that produced 3-D representations of the shattered city. A lot of the damage could have been prevented with better engineering. They found buildings that never would have collapsed if they’d used simple reinforcements. Unfortunately, however, the local building code lagged behind recent discoveries. But some buildings weren’t up to the local code, either—mostly because builders couldn’t afford the reinforcements and structural planning required. The more earthquake-proof a building is, the more expensive it gets. That’s why Takhirov tries to be pragmatic about earthquake engineering. When builders have to cut corners, they should always prioritize human safety over a building’s durability. “Sometimes it’s more cost effective to have a building that will be damaged but not collapse,” Takhirov explained. “That way people can escape, even if you have major damage.”

Читать дальше

![Аннали Ньюиц - Автономность [litres]](/books/424681/annali-nyuic-avtonomnost-litres-thumb.webp)