1 Cover

2 Series Preface Series Preface The Wiley‐ASME Press Series in Mechanical Engineering brings together two established leaders in mechanical engineering publishing to deliver high‐quality, peer‐reviewed books covering topics of current interest to engineers and researchers worldwide. The series publishes across the breadth of mechanical engineering, comprising research, design and development, and manufacturing. It includes monographs, references and course texts. Prospective topics include emerging and advanced technologies in Engineering Design; Computer‐Aided Design; Energy Conversion & Resources; Heat Transfer; Manufacturing & Processing; Systems & Devices; Renewable Energy; Robotics; and Biotechnology.

3 Preface

4 Glossary

5 About the Companion Website

6 Part I: Fundamentals of Engineering Science 1 Review of Basic Principles1.1 Engineering Mechanics 1.2 Fluid Mechanics 1.3 ThermodynamicsEngineering Mechanics Fluid Mechanics Thermodynamics 2 Thermodynamics of Reactive Mixtures 2.1 Fuels 2.2 Stoichiometry 2.3 Chemical Reactions 2.4 Thermodynamic Properties of the Combustion Products 2.5 First Law Analysis of Reacting Mixtures 2.6 Adiabatic Flame Temperature 2.7 Entropy Change in Reacting Mixtures 2.8 Second Law Analysis of Reacting Mixtures 2.9 Chemical and Phase Equilibrium 2.10 Multi‐Species Equilibrium Composition of Combustion Products

7 Part II: Reciprocating Internal Combustion Engines 3 Ideal Cycles for Natural‐Induction Reciprocating Engines 3.1 Generalised Cycle 3.2 Constant‐Volume Cycle (Otto Cycle) 3.3 Constant Pressure (Diesel) Cycle 3.4 Dual Cycle (Pressure‐Limited Cycle) 3.5 Cycle Comparison 4 Ideal Cycles for Forced‐Induction Reciprocating Engines 4.1 Turbocharged Cycles 4.2 Supercharged Cycles 4.3 Forced Induction Cycles with Intercooling 4.4 Comparison of Boosted Cycles 5 Fuel‐Air Cycles for Reciprocating Engines 5.1 Fuel‐Air Cycle Assumptions 5.2 Compression Process 5.3 Combustion Process 5.4 Expansion Process 5.5 Mean Effective Pressure 5.6 Cycle Comparison 6 Practical Cycles for Reciprocating Engines 6.1 Four‐Stroke Engine 6.2 Two‐Stroke Engine 6.3 Practical Cycles for Four‐Stroke Engines 6.4 Cycle Comparison 6.5 Cycles Based on Combustion Modelling (Wiebe Function) 6.6 Example of Wiebe Function Application 6.7 Double Wiebe Models 6.8 Computer‐Aided Engine Simulation 7 Work‐Transfer System in Reciprocating Engines 7.1 Kinematics of the Piston‐Crank Mechanism 7.2 Dynamics of the Reciprocating Mechanism 7.3 Multi‐Cylinder Engines 7.4 Engine Balancing 8 Reciprocating Engine Performance Characteristics8.1 Indicator Diagrams 8.2 Indicated Parameters 8.3 Brake Parameters 8.4 Engine Design Point and Performance 8.5 Off‐Design Performance

8 Part III: Gas Turbine Internal Combustion Engines 9 Air‐Standard Gas Turbine Cycles 9.1 Joule‐Brayton Ideal Cycle 9.2 Cycle with Heat Exchange (Regeneration) 9.3 Cycle with Reheat 9.4 Cycle with Intercooling 9.5 Cycle with Heat Exchange and Reheat 9.6 Cycle with Heat Exchange and Intercooling 9.7 Cycle with Heat Exchange, Reheat, and Intercooling 9.8 Cycle Comparison 10 Irreversible Air‐Standard Gas Turbine Cycles 10.1 Component Efficiencies 10.2 Simple Irreversible Cycle 10.3 Irreversible Cycle with Heat Exchange (Regenerative Irreversible Cycle) 10.4 Irreversible Cycle with Reheat 10.5 Irreversible Cycle with Intercooling 10.6 Irreversible Cycle with Heat Exchange and Reheat 10.7 Irreversible Cycle with Heat Exchange and Intercooling 10.8 Irreversible Cycle with Heat Exchange, Reheat, and Intercooling 10.9 Comparison of Irreversible Cycles 11 Practical Gas Turbine Cycles 11.1 Simple Single‐Shaft Gas Turbine 11.2 Thermodynamic Properties of Air 11.3 Compression Process in the Compressor 11.4 Combustion Process 11.5 Expansion Process in the Turbine 12 Design‐Point Calculations of Aviation Gas Turbines 12.1 Properties of Air 12.2 Simple Turbojet Engine 12.3 Performance of Turbojet Engine – Case Study 12.4 Two‐Spool Unmixed‐Flow Turbofan Engine 12.5 Performance of Two‐Spool Unmixed‐Flow Turbofan Engine – Case Study 12.6 Two‐Spool Mixed‐Flow Turbofan Engine 12.7 Performance of Two‐Spool Mixed‐Flow Turbofan Engine – Case Study 13 Design‐Point Calculations of Industrial Gas Turbines 13.1 Single‐Shaft Gas Turbine Engine 13.2 Performance of Single‐Shaft Gas Turbine Engine – Case Study 13.3 Two‐Shaft Gas Turbine Engine 13.4 Performance of Two‐Shaft Gas Turbine Engine – Case Study 14 Work‐Transfer System in Gas Turbines 14.1 Axial‐Flow Compressors 14.2 Radial‐Flow Compressors 14.3 Axial‐Flow Turbines 14.4 Radial‐Flow Turbines 15 Off‐Design Performance of Gas Turbines 15.1 Component‐Matching Method 15.2 Thermo‐Gas‐Dynamic Matching Method

9 Bibliography

10 Appendix A Thermodynamic Tables

11 Appendix B Dynamics of the Reciprocating Mechanism

12 Appendix C Design Point Calculations – Reciprocating Engines C.1. Engine Processes

13 Appendix D Equations for the Thermal Efficiency and Specific Work of Theoretical Gas Turbine Cycles Nomenclature

14 Index

15 End User License Agreement

1 Chapter 1 Table 1.1 Equations of motion for linear and rotational motions. Table 1.2 Symbols, units, and dimensions of common physical quantities. Table 1.3 Coefficients of Eq. (1.99) for the calculation of  of combustion produ... Table 1.4 Coefficients of Eq. (1.100) for the calculation of

of combustion produ... Table 1.4 Coefficients of Eq. (1.100) for the calculation of  of air.

of air.

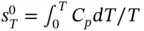

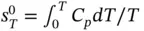

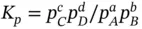

2 Chapter 2 Table 2.1 Typical carbon, hydrogen, and sulfur mass contents of common fuels. Table 2.2 Composition of air. Table 2.3 Volume composition of some gaseous fuels. Table 2.4 Typical carbon, hydrogen, oxygen, and sulfur mass contents of common l... Table 2.5 Stoichiometric reactions of the elements of a liquid or solid fuel.Table 2.6 Coefficients a nin Eq. (2.38) for specific heats at constant pressure o...Table 2.7 Coefficients a nin Eq. (2.47) for internal energies of air and combusti...Table 2.8 Composition and heating values of some liquid, gaseous, and solid fuel...Table 2.9 Coefficients a nin Eq. (2.62) for air and combustion products ( T = 300–...Table 2.10 Adiabatic flame temperature of octane ( C 8 H 18) vs. relative air‐fuel r...Table 2.11 Entropy change data for combustion of methane.Table 2.12 Equilibrium constant  for the reaction aA + bB ⇄ cC + dD...Table 2.13 Equilibrium constants for dissociation reactions in products with six...Table 2.14 Equilibrium constants for dissociation reactions in products with 11 ...Table 2.15 Equilibrium constants for dissociation reactions in products with 18 ...Table 2.16 Adiabatic flame temperature for frozen and equilibrium compositions o...

for the reaction aA + bB ⇄ cC + dD...Table 2.13 Equilibrium constants for dissociation reactions in products with six...Table 2.14 Equilibrium constants for dissociation reactions in products with 11 ...Table 2.15 Equilibrium constants for dissociation reactions in products with 18 ...Table 2.16 Adiabatic flame temperature for frozen and equilibrium compositions o...

3 Chapter 5Table 5.1 Typical values of the parameters of the compression process in real en...Table 5.2 Typical values of the parameters of the expansion process in real engi...Table 5.3 Operating and performance parameters of fuel‐air and air‐standard cycl...

4 Chapter 6Table 6.1 Operating and performance parameters of the dual‐combustion air‐standa...Table 6.2 Double Wiebe parameter values.

5 Chapter 7Table 7.1 Data for calculations of forces on piston and crank pin.Table 7.2 Effect of the number of cylinders on the torque uniformity factor and ...

Читать дальше

of combustion produ... Table 1.4 Coefficients of Eq. (1.100) for the calculation of

of combustion produ... Table 1.4 Coefficients of Eq. (1.100) for the calculation of  of air.

of air. for the reaction aA + bB ⇄ cC + dD...Table 2.13 Equilibrium constants for dissociation reactions in products with six...Table 2.14 Equilibrium constants for dissociation reactions in products with 11 ...Table 2.15 Equilibrium constants for dissociation reactions in products with 18 ...Table 2.16 Adiabatic flame temperature for frozen and equilibrium compositions o...

for the reaction aA + bB ⇄ cC + dD...Table 2.13 Equilibrium constants for dissociation reactions in products with six...Table 2.14 Equilibrium constants for dissociation reactions in products with 11 ...Table 2.15 Equilibrium constants for dissociation reactions in products with 18 ...Table 2.16 Adiabatic flame temperature for frozen and equilibrium compositions o...