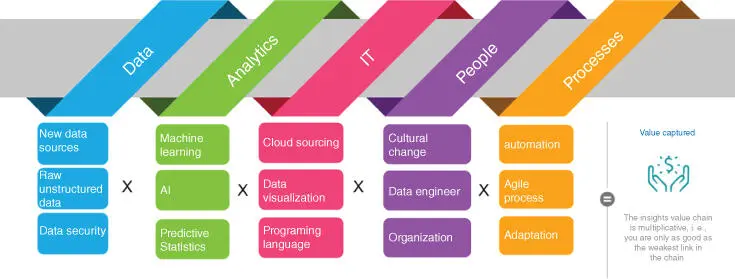

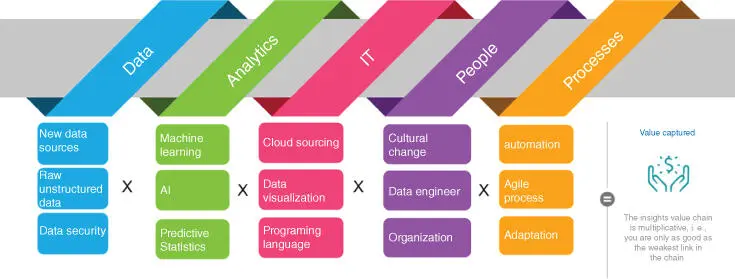

The following sections briefly explain the function of each of the insights value chain's core components (see Figure 2.5) along with its upstream as well as its downstream steps and processes.

Figure 2.4Different components of the insights value chain

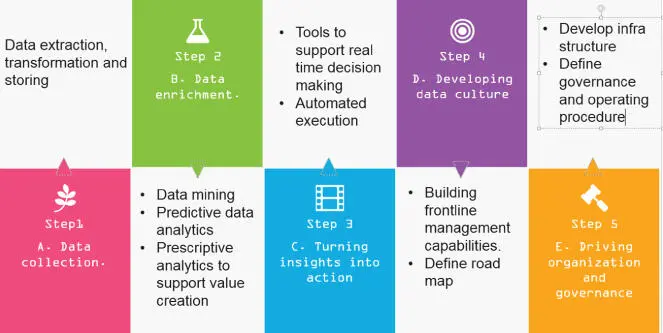

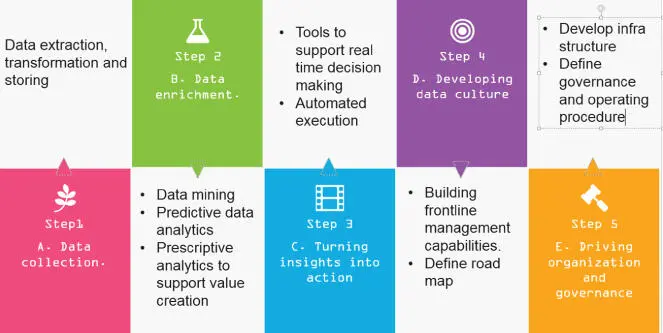

Figure 2.5Overview of the insights value chain upstream processes (A–B) and downstream activities (D–E)

2.5.2.1 The Insights Value Chain – Definitions and Considerations (Holger Hürtgen, 2018)

The insights value chain has two foundations, namely a technical foundation and a business foundation. The technical component of the technical foundation consists of data, analytics (algorithms and technical talent), and an IT infrastructure (Hürtgen, 2018). This essentially means that the value creation from data is possible when efficient data scientists and domain experts use smart algorithms to extract meaningful information from high‐quality data. In today's world of Big Data, companies also need an IT infrastructure capable of capturing, storing, and processing large amounts of data fast. Second, the business foundations of the insights value chain consist of the components of people (non‐technical talent) and the company's adaptive processes, both of which are required to turn the knowledge gain from data into (business) action.

Here are some key considerations concerning the components of the insights value chain:

Data: The basic building block of this value chain is data and data must be thought of as the entire process of collecting, linking, cleaning, enriching, and augmenting internal information (potentially with additional external data sources). In addition, the security and privacy of the data throughout the process are fundamental.

Analytics: The second component of the insights value chain is the data analytics, which can be considered as an IC engine that will utilize the data (new oil) to generate business insights. Analytics describes the set of digital algorithms (e.g. software) deployed to extract knowledge from data as well as the talent (e.g. data engineers and data scientists, domain experts in the chemical industry) capable of deploying the right tools and methods.

IT: IT infrastructure is the technical layer enabling the capturing, storing, and processing of data, e.g. data lakes, two‐speed IT architecture.

People: People are the ultimate drivers who will implement those insights in business actions. People from the front lines of manufacturing and sales are needed to guide and run an advance analytics course that converts data into insights and successfully implements those insights in the business. Today's chemical companies need to change the old mindset and should develop this critical capability to “translate” analytics‐ and data‐driven insights into business implications and actions.

Process: Another crucial challenge in the digital journey is to develop adaptive processes and systems within the company that can deliver these business actions at scale. To develop the ability of seamless implementation, some old operating procedures might need to be adapted, some might need to be fully automated, and others might need to be made more agile.

In addition, there is an overarching frame and an underlying governance in which the insights value chain is operating:

Strategy and vision are the overarching frames in which the insights value chain is meant to operate. Data analytics should not be “done” for the sake of a data analytics but in fulfillment of the organization's vision and in support of its overall business strategy. “Think business backwards, not data forward” (Holger Hürtgen, 2018).

The operating model is the underlying governance in which the insights value chain lives. Core matters to be addressed include deciding where the analytics unit will sit within the organization and how it will function and interact with BUs (e.g. centralized, decentralized, hybrid).

2.6 From Dull Data to Critical Business Insights: The Upstream Processes

The insights value chain's upstream processes comprise two steps (see Figure 2.5).

2.6.1 Generating and Collecting Relevant Data

Today's big chemical complexes have at least 10–20 plants and each plant consists of approximately 4000–7000 transmitters or sensors that can collect data every second (Holger Hürtgen, 2018). For instance, a petrochemical complex having 10 individual chemical plants generates 3.127 trillion data in one year. It is very costly (and perhaps impossible) to capture and save every bit of the tera‐ and petabytes of data that will be generated every second and will create a data overload on the system. Not all the data are relevant to make an impact on the business in the chemical industry. Hence it is important to know which data should be collected and at which frequency so that it can be used to generate business insights and drive the profits up. One easy solution is to follow the use case earlier implemented in any other chemical industry. Defining certain requirements based on particular use cases will help ensure that only relevant data are captured.

As shown in the study of Mckinsey, the situation requires a vision and critical thinking to find which data to store in its original granularity and which to aggregate or pre‐analyze. In the case of relevance, the more classical “hypothesis‐driven” or “use case backwards” approach often delivers better results than the often praised “Big Data, brute force” approach.

Data layering is another critical requirement while handling enormous volumes of data of the chemical industry. Instead of overloading the data analytic algorithm with all types of raw data, carefully organizing it into several logical layers and then employing a logic by which to stack these layers can help generate more meaningful data.

2.6.2 Data Refinement is a Two‐Step Iteration

Once all relevant raw data of the chemical industry is captured and stored, the next step is the process of translating the enormous amount of unrefined raw data into actionable business insights. This is a very critical step and here lie all the challenges. The two‐step process is comprised of enrichment and extraction (Holger Hürtgen, 2018).

1 Step 1: Enriching data with additional information and/or domain knowledge. It is important to understand that a data engineer working alone is not sufficient to do this translation. A domain expert who runs the chemical company is absolutely necessary to enrich the data with additional domain knowledge – which is a somewhat more complex process. This essentially means that human expertise and domain knowledge is as important to making data useful as is the power of analytics and algorithms.

The blend of data analytics capability along with a domain expert's knowledge is still the optimal approach to data enrichment, although this may well change one day due to further developments in AI space. Therefore, before we even start with machine learning, we need to involve human experts who use their expertise to explain their hypotheses.

The task of a data scientist (or sometimes a data engineer at this stage) is now to translate, i.e. codify, additional information and/or this domain knowledge into variables. Concretely, this means transforming existing data into new variables – often also called feature engineering.

Читать дальше