Siegfried Siegesmund - Monument Future

Здесь есть возможность читать онлайн «Siegfried Siegesmund - Monument Future» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на немецком языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Monument Future

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:4 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

Monument Future: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Monument Future»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Alle vier Jahre treffen sich auf einer internationalen Tagung Experten, die sich mit den entsprechenden Sachfragen beschäftigen. Der „14th International Congress on the Deterioration and Conservation of Stone“ findet im September 2020 in Göttingen statt. Er ist die wichtigste Veranstaltung zur Verbreitung des Wissens von Praktikern und Forschern, die im Bereich der Steinkonservierung zur Erhaltung des baulichen Kulturerbes arbeiten: Geowissenschaftler, Architekten, Bauspezialisten, Ingenieure, Restauratoren, Denkmalpfleger und Bauherren.

Der Tagungsband mit über 150 wissenschaftlichen Beiträgen repräsentiert und erfasst den neuesten Stand der Technik auf diesem Gebiet.

Themen sind:

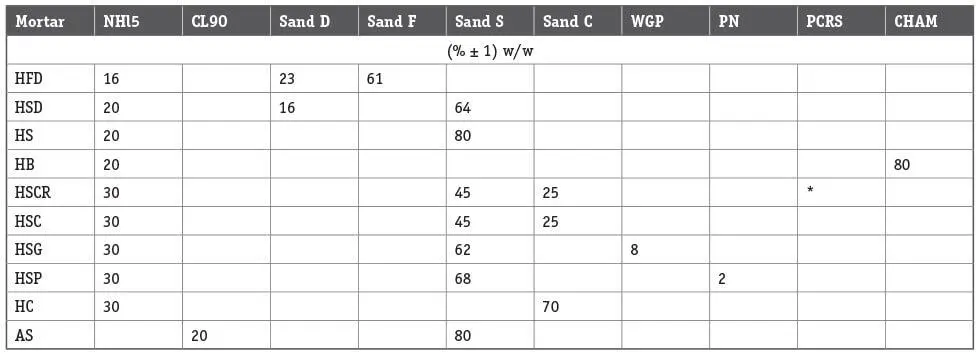

– Charakterisierung von Schadensphänomenen von Steinen und verwandten Baumaterialien (Stuck, Putz, Mörtel usw.)

– Methoden zur Untersuchung des Steinverfalls in situ und zerstörungsfreie Prüfung

– Langzeitüberwachung von Steindenkmälern und Gebäuden

– Simulation und Modellierung des Zerfalls

– Technologien und Entwicklung verbesserter Bearbeitung und Verwendung von Stein in Neubauten

– Bewertung der Langzeitwirkung von Bearbeitungstechniken

– Auswirkungen des Klimawandels auf die Steinverwitterung des Kulturerbes

– Berichte zur Steinkonservierung: Fallstudien und Projekte

– Digitalisierung und Dokumentation von Steinkonservierung

–

The 14th International Congress on the Deterioration and Conservation of Stone, entitled MONUMENT FUTURE: DECAY AND CONSERVATION OF STONE is a quadrennial event that brings together a world-wide community of geoscientists, architects, building specialists, engineers, conservators, restorators, monument curators and building owners who are concerned about the conservation of cultural stone structures and objects. Since antiquity, the weathering and deterioration of historical buildings, masonry, monuments, sculptures etc. using natural stones has been a very well-known problem.

This conference is the main gathering for the dissemination of knowledge in the field of stone deterioration issues. It represents and captures the state-of-the-art in the field of stone conservation and cultural heritage conservation with regards to the following topics:

– Characterisation of damage phenomena of stone and related building materials (plaster, rendering, mortar etc.)

– Methods for the investigation of stone decay; in-situ and non-destructive testing

– Long-term monitoring of stone monuments and buildings

– Simulation and modelling of decay

– Technology and development of improved treatments and use of stone in new buildings

– Assessment of long-term effects of treatments

– Impact of climate change on stone decay of Cultural Heritage

– Reports about stone conservation: case studies and projects

– Digitalization and documentation in stone conservation