Copolymers of ethylene, such as ethylene‐vinyl acetate (EVA) and ethylene‐vinyl alcohol (EVOH), are typically used to make lid films for trays and barrier interlayers.

Polyesters, such as polyethylene terephthalate (PET) and other aliphatic and aromatic polyesters, are mainly used to make water bottles.

Polyamides (PAs) are commonly employed in films or trays for food products that are very sensitive to oxygen.

Most of these materials are made by condensation or addition polymerization of monomers of hydrocarbon or hydrocarbon‐like raw materials, which means that due to their fossil‐based nature and high chemical stability, they are not biodegradable and will accumulate in landfills over the years, causing a negative impact on the environment. Although several recycling strategies are currently being carried out, packaging materials are often contaminated with leftover food, making recycling economically inconvenient and thus unviable. In 2010, primary plastic production was 270 million tons, yet plastic waste was 275 million tons since plastics produced in previous years entered the waste stream, where the sector of packaging was the highest producer of plastics, that is, 146 million in 2015. This has led to an increase in the number of campaigns requesting the removal of single‐use plastics, with the European parliament aiming to ban single‐use plastic cutlery, cotton buds, straws, and stirrers by 2021. Such environmental awareness and implementation of stringent environmental regulations are leading to research for alternatives to food packaging materials and, thus, efforts are being directed, at both academic and industrial levels, at the use of bioplastics in a variety of consumer products.

1.2 Classification of Biopolymers

The above‐described environmental issues, together with the scarcity of oil sources, are the main drivers behind the interest for the development of new materials for food packaging applications. Although bioplastics only account for 1% of the approximately 350 million tons of plastics produced annually, being mostly applied as packaging materials [6, 7], including high‐performance thermoplastic materials and foams, they represent an important part of the Bioeconomy and will undoubtedly shape the future of the plastic industry [8]. As a result, the use of biopolymers in packaging has increased considerably over the past few years due to their sustainable feedstock, biodegradability, and similar processing characteristics as existing thermoplastics [9].

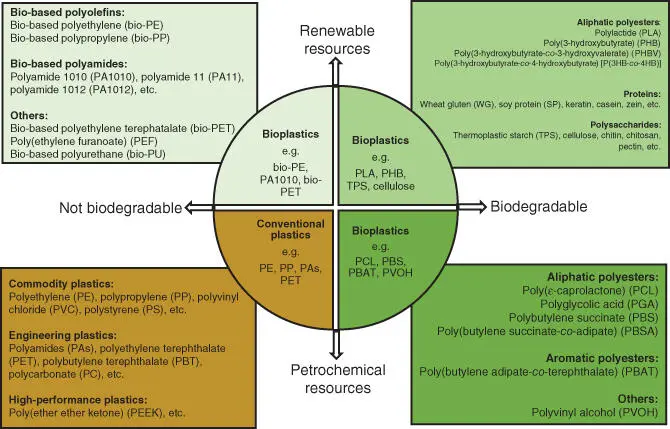

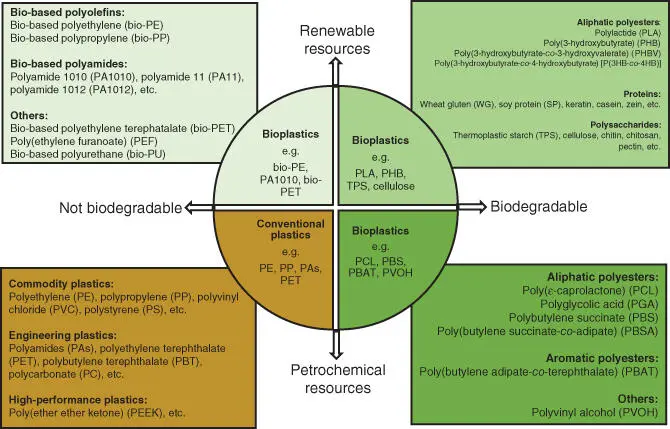

Biopolymers comprise of a whole family of materials with different properties and applications. They include polymers with a “bio‐based” origin and “biodegradable” polymers or polymers featuring both properties. Bio‐based polymers refer to any kind of polymer that is produced from renewable resources, which include both naturally occurring polymers and synthetic polymers produced by means of monomers obtained from biological sources [10]. Naturally occurring polymers are biomacromolecules, that is, molecules of large molecular weights ( M W) produced in nature by living organisms and plants. Biodegradable polymers are defined as those polymer materials whose physical and chemical properties undergo deterioration and completely degrade, when exposed to the enzymatic action of microorganisms, to carbon dioxide (aerobic process), methane (anaerobic process), water (aerobic and anaerobic processes), inorganic compounds, and biomass [11]. Bio‐based polymers can be biodegradable but not all biodegradable polymers are bio‐based. Additionally, some synthetic biodegradable polymers could be in a near future partially or fully developed from bio‐based monomers. Bio‐based polymers offer the advantage of conservation of fossil resources by using biomass that regenerates (annually) and the unique potential of carbon neutrality whereas biodegradability is an add‐on property of certain types of polymers that offers additional means of recovery at the end of a product's life [12, 13].

Figure 1.1 Classification of biopolymers widely used in packaging.

Figure 1.1summarizes the classification of biopolymers grouped according to their origin and biodegradability characteristics. On the top right of the figure, bio‐based and biodegradable polymers are gathered. Nature produces over 170 billion metric tons per year of biomass, yet only 3–4% of this material is being used by humans for food and nonfood purposes [14]. Biomass derived carbohydrates are the most abundant renewable resources available, representing approximately 75% of this biomass, which are currently regarded as the basis for the green chemistry of the future. Most of these biopolymers are mainly made from carbohydrate‐rich plants such as corn or sugarcane, that is, the so‐called food crops, which are also currently referred to as the “first generation feedstock” of bioplastics. This currently represents the most efficient feedstock for the production of bioplastics, as it requires the least amount of land to grow and produce the highest yields. Biomass derived polyesters such as polylactide (PLA) and thermoplastic starch (TPS) are among the most promising biodegradable polymers and they contribute to up to 65% of the family of this type of biopolymers.

The same durability properties that have made traditional petroleum derived plastics ideal for many applications, such as those found in packaging, are leading to terrible waste‐disposal problems as these materials are resistant to microbial degradation and plastics accumulate in the environment. For this reason, some biodegradable polymers, yet based on petrochemical polymers, have been developed in the last few years. The most frequently studied polymers are included in the bottom‐right group, which are aliphatic or aliphatic–aromatic polyesters since neat aromatic polyesters based on terephthalic acid are generally insensitive to hydrolytic degradation and to enzymatic or microbial attack due to their high stability. Indeed, the biodegradation rate increases rapidly when the concentration of terephthalic acid becomes lower than 55 mol%. These petrochemical biodegradable polymers can find several uses in both flexible and rigid packaging applications.

Bio‐based but not biodegradable polymers, which are shown at the top‐left of the figure, currently offer important contributions by reducing the dependence on fossil fuels and through the related positive environmental impact, that is, reduced carbon dioxide emissions. New approaches go toward the complete or partial substitution of conventional plastics by renewable resources such as biomass [15]. Conventional polymers from feedstock routes are being explored for well‐known applications, including the packaging industry [16]. These are generally based on monomers derived from agricultural and food‐based resources such as corn, potatoes, and other carbohydrate feedstock. The new branch of these “green polymers” reflects the “biorefinery” concept [17]. The monomers to produce these bio‐based polymers can be obtained from natural resources, for example catalytic dehydration of bioethanol obtained by microbial fermentation. Although these biopolymers are not biodegradable, they have the same processing and performance as conventional polymers made from natural gas or oil feedstocks. Such developments have recently led to the new paradigm for sustainable food packaging: “Bio‐based but not biodegradable” [18]. This is further evidenced by the recent development of fully bio‐based polyethylene terephthalate (bio‐PET), where the ethylene glycol and the terephthalic acid are both derived from plant‐based sugars and agricultural residues.

Читать дальше