HSE report RR 684 (HSE 2009) states that an inspection strategy should be:

consistent with the structural integrity strategy and SIM processes including structural evaluation, assessment, maintenance and information management requirements;

able to determine with reasonable level of confidence the existence and extent of deterioration, defects and damage;

able to address the motives for inspection listed by ISO 19902 (ISO 2007);

developed and maintained by a competent person, using appropriate experience, data and, where required, analysis

able to specify the tools and techniques to be used; and

documented.

The report (HSE 2009) further states that an inspection programme should be developed from the integrity management policy and strategy. It requires schedules, budgets, personnel profiles, inspection procedures for implementation. Guidance on developing an inspection programme is given in ISO 19902 (ISO 2007) and API RP‐2SIM (API 2014b).

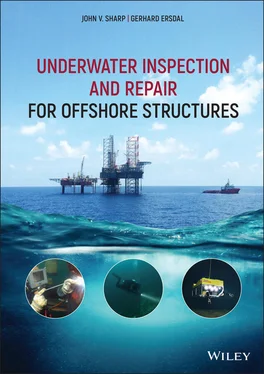

A structural integrity management framework is proposed as shown in Figure 10, based on what the authors consider to be the best practice from the various standards reviewed in this chapter. Each element of the process is to varying degrees included in each of these standards and recommended practices. Inspection is a major feature of “as‐is surveillance” and repair is a key factor in “mitigating measures”.

Most standards in detail include the middle “as‐is surveillance” process with the six sub‐processes and also include guidance on “integrity assessment” and “mitigation measures”.

However, very few of the standards give guidance on hazard identification and establishing the risk picture of the structure and marine system. Two exemplary exceptions are API RP 2MIM (API2019b), which includes an annex on “causes of failure” and API RP 2FSIM (API 2019a), which includes an annex on “Damage and failure modes”, both with valuable information for hazard identification and risk management.

Many standards and recommended practices also implicitly include information and guidance on operational limitations, such as the design events, the size of vessels assumed to be visiting the platform and the importance of knowing the weight of the topside and the inventory. However, the standards and recommended practices do not necessarily give guidance on its importance for the operation of the platform or how to operate in situations outside the operational limitations. For floating structures, several relevant issues are often included in the marine operational manual.

Emergency preparedness and emergency response planning should be performed for reasonably foreseeable situations that may occur in normal and in severe conditions. This seems to be an area where the structural and marine engineers rely on the traditional emergency response discipline to understand structures and marine systems. As a result, only one standard is providing guidance on this topic. This exemplary exception is API RP‐2MIM (API 2019b), which includes an annex on “incident response planning”.

As a result, it can be concluded that for some of the important factors, the standards and recommended practices have limited information. This book attempts to bridge these gaps.

1 ABS (2017), “Inspection Grading Criteria for the ABS Hull Inspection and Maintenance Programme (HIMP)”, American Bureau of Shipping, 2017.

2 API (1969), RP‐2A Recommended Practice for Planning, Design and Constructing Fixed Offshore Platforms. API Recommended practice 2A, 1st edition, American Petroleum Institute, 1969.

3 API (2005), API RP‐2SK Design and Analysis of Stationkeeping Systems for Floating Structures, Third Edition, American Petroleum Institute, 2005.

4 API (2008), API RP‐2I In‐service Inspection of Mooring Hardware for Floating Structures, Third Edition, American Petroleum Institute, 2008.

5 API (2011), API RP 2FPS Recommended Practice for Planning, Designing and Constructing Floating Production Systems, American Petroleum Institute, 2011.

6 API (2014a), API RP‐2A Recommended Practice for Planning, Design and Constructing Fixed Offshore Platforms. API Recommended practice 2A, 22nd Edition, American Petroleum Institute, 2014.

7 API (2014b), API RP‐2SIM Recommended Practice for Structural Integrity Management of Fixed Offshore Structures, American Petroleum Institute, 2014.

8 API (2015), API RP‐2T Recommended Practice for Planning, Designing and Constructing Tension Leg Platforms, Third Edition, American Petroleum Institute, 2015.

9 API (2016), API RP 579‐1 / ASME FFS‐1, Fitness‐For‐Service, Third Edition, American Petroleum Institute 2016.

10 API (2019a), API RP‐2FSIM Floating System Integrity management, American Petroleum Institute, 2019.

11 API (2019b), API RP‐2MIM Mooring Integrity Management, American Petroleum Institute, 2019.

12 ASTM (2015), ASTM C876‐15 Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete, ASTM International.

13 BSI (2008), PAS55 Asset Management, British Standardisation Institute.

14 Cullen, The Hon Lord (1990). The Public Enquiry into the Piper Alpha Disaster, HMSO, London, UK

15 Department of Energy (1974), The Offshore Installations (Construction and Survey) Regulations, HMSO, London, UK.

16 Department of Energy (1990), Offshore Installations: Guidance on Design, Construction and Certification, Fourth Edition, HMSO, London.

17 DNVGL (2018), DNVGL‐OS‐E301 Position Mooring, DNVGL, Høvik, Norway.

18 HSE (1990), Effect of Bacterial Activity on North Sea Concrete, Undertaken by Khoury G.A, Sullivan P.J.E., OTH 90 320, HSE Books, London, UK.

19 HSE (1996). The Offshore Installations and Wells (Design and Construction, etc) Regulations, Health and Safety Executive (HSE) SI 1996/913.

20 HSE (1997) “Guidance for Concrete structures – Background Report”, HSE OTO Report 96 050.

21 HSE (2005), Offshore Installations (Safety Case) Regulations, Health and Safety Executive (HSE), HSE Books, London, UK.

22 HSE (2009), “HSE RR684—Structural Integrity Management Framework for Fixed Jacket Structures”, Health and Safety Executive (HSE), London, UK.

23 HSE (2013), “Managing for Health and Safety, HSG 65”, Health and Safety Executive (HSE), London, UK.

24 HSE (2019), “HSE Offshore Information Sheet 4/2013 Offshore Installation moorings Rev.3”, Health and Safety Executive (HSE), London, UK.

25 IACS (2010). “Guidelines for the Survey of Offshore Chain Cable in use, No. 38, 2010”, International Association of Classification Societies (IACS).

26 ISO (2006), “ISO 19904:2006 Petroleum and Natural Gas Industries—Floating Offshore Structures”, International Standardisation Organisation, 2006.

27 ISO (2007), “ISO 19902:2007 Petroleum and Natural Gas Industries—Fixed Steel Offshore Structures”, International Standardisation Organisation.

28 ISO (2013), “ISO 19901‐7:2013 Petroleum and Natural Gas Industries—Specific Requirements for Offshore Structures—Part 7: Stationkeeping Systems for Floating Offshore Structures and Mobile Offshore Units”, International Standardisation Organisation, 2013.

29 ISO (2019a), “ISO 19901‐9 Petroleum and Natural Gas Industries—Specific Requirements for Offshore Structures—Part 9: Structural Integrity Management”, International Standardisation Organisation, 2019.

30 ISO (2019b), “ISO 19903 Petroleum and Natural Gas Industries—Fixed Concrete Offshore Structures”, International Standardisation Organisation, 2019.

31 Lloyds Register (2019), “Lloyds Register Rules for Classification Floating Units at Fixed location—Part 3”, Lloyd Register. London. UK.

32 NMD (2009), “Anchoring Regulations of 10 July 2009, No.998”, Norwegian Maritime Directorate.

Читать дальше