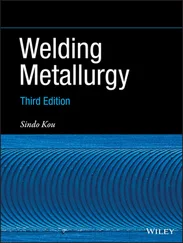

Library of Congress Cataloging-in-Publication Data

ISBN 978-1-119-81905-9

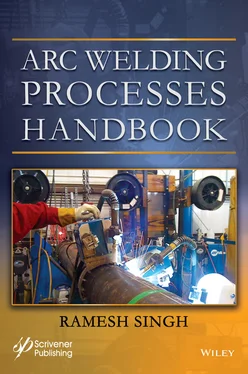

Cover image: Double headed GMAW system provided by the author

Cover design by Russell Richardson

Set in size of 11pt and Minion Pro by Manila Typesetting Company, Makati, Philippines

Printed in the USA

10 9 8 7 6 5 4 3 2 1

Figure 1.1 General lay out of welding and joining processes

Figure 2.3 A SMAW welder welding on a pipeline project

Figure 2.4 Typical SMAW setup

Figure 2.5 Welding arc action and various components of welding

Figure 2.6 Above (2 graphs), graph 1 above, shows the volt-ampere curve, (output curve or slope) at lower stings. Graph 2 below, shows the volt-ampere curve, (output curve or slope) the steep slope of a “Drooper” type of constant current arc welder

Figure 2.7 The schematic above shows the key components of an AC transformer

Figure 2.7.3 Schematic of a movable shunt type transformer control

Figure 2.7.4 A schematic of a movable coil reactor, the position of the reactor coil causes the inductive reactance of the secondary output coil resulting in the variance in current output

Figure 2.7.5 A magnetic amplifier transformer output control, the diode allows the current to flow in one direction, and this allows a remote control operation possible

Figure 2.7.6 The top portion of the figure shows the use of diodes – shown in Red color, and it compare it with Silicon controlled rectifiers (SCRs)

Figure 2.7.7 A schematic drawing of single-phase DC power source with SCR bridge control

Figure 2.8.1 Shows the schematic of single phase bridge type rectifier

Figure 2.8.2 Three phase bridge-type rectifier

Figure 2.8.1.1 Schematic diagram of a DC generator

Figure 2.8.1.2 Circuitry of an exciter system

Figure 2.8.3 Current conversion and resulting wave forms

Figure 2.8.3.1 Copper and aluminum welding leads: note the number of fine wires that compose a cable, and the rubber sheathing that covers them

Figure 2.8.3.2 Different types of SMAW electrode holders

Figure 2.8.4.1 Various types of cable connectors, and ground clamp. Pictures courtesy of LENCO ®catalogue

Figure 2.8.5.1 NEMA rating

Figure 2.9.1 A typical hand-held welding shield

Figure 2.9.2 Miller Digital Elite helmet

Figure 2.9.3 A typical welding helmet

Figure 2.10.2 Portfolio of SMAW electrodes

Figure 2.10.3 AWS electrode classification method

Figure 2.10.5.1 Shop use electrode drying oven

Figure 2.10.5.2 Portable electrode holder also called quivers

Figure 2.11.1 Different types of weld joints

Figure 2.11.2 Different types of weld designs

Figure 2.11.3 Welding positions for welding a plate, the positions are primarily designated in relation to the position of the weld to the horizontal surface of the earth

Figure 2.11.4 Positions of plate and pipe butt welds and fillet welds with both AWS and European designations

Figure 2.11.5 Above figure shows the permitted angular tolerance for specifically designated welding positions for pipe welding

Figure 2.11.3.1 Testing a fillet weld

Figure 2.11.3.2 Testing a fillet weld using a hammer

Figure 2.11.3.3 Size and nomenclature of fillet weld

Figure 2.11.3.4 A single pass fillet weld

Figure 2.11.3.5 A single pass fillet weld with (arc termination) stop in the middle and restarted (arc re-initiation) from that point

Figure 2.11.3.6 A multi-passes fillet weld-note the termination of arc start and stops are staggered

Figure 2.11.3.7 A micro-etch of a double sided two pass fillet weld – compare the weld with the nomenclatures figure given above, to see how these two welds meet the standard requirements

Figure 2.11.4.1 Weld appearances matched with arc current, and arc travel speed

Figure 2.11.4.2 Pictures of the weld appearances and probable cause for the quality of weld produced

Figure 2.11.5.1 Offsetting the weld setup for distortion control

Figure 2.11.9 This is a rotator with one end of the pipe held in a three-jaw, self-centering chuck the free end of the pipe rests on a free rotating roller, it can be raised or lowered to level the pipe to align the weld ends

Figure 2.11.10 This rotator is similar to the one above except that the pipe end is placed on a motor driven set of rollers on one end, and the other end is on the set of idle rollers, which can be lowered or raised to align and level the weld joint

Figure 2.11.11 A heavy-duty rotator

Figure 2.11.12 Weld tacks bridging two pieces of pipe

Figure 2.11.13 Shows a removable tack

Figure 2.11.14 This picture shows both the bridge tack using external pieces of metal below, and just above that is the tack within the groove using welding

Figure 2.11.15 Typical CS pipe weld

Figure 2.11.10.1 Bevel edge preparation for vertical-up pipe in 6G position

Figure 2.11.10.2 The vertical up progression – note the direction of electrode movement

Figure 2.11.11.1 Vertical down progression

Figure 2.11.11.2 Weld profile of each pass

Figure 2.11.11.3 The sketch above shows a typical weld layers of several passes - note the sequencing numbers on each pass

Figure 2.12.6 Aluminum fillet weld-bend testing

Figure 2.12.12 Typical stainless-steel pipe weld, and weld-o-let on the header

Figure 2.12.13 Pipe is assembled and prior to welding, the welder is tacking them with the GTAW process

Figure 2.12.18 Schaeffler diagram

Figure 2.12.19 DeLong diagram

Figure 2.14 Nickel alloy plate being welded

Figure 2.1 Nickel is in 10th group and 4th period in the periodic table, its atomic number is

Figure 2.14.2 Typical nickel welding electrodes – note the electrode identification making on the electrode

Figure 2.14.3 Nickel alloy welding (note the fillet weld in upward progression)

Figure 3.3.1 Typical GTAW welding

Figure 3.3.2 A GTAW welder, note the welding torch, and the filler wire in each hand

Figure 3.4.1 Typical GTAW welding process with details of the welding torch

Figure 3.5.1 A typical GTAW set-up with positions of gas cylinder, welding machine, electrode holder and work-piece

Figure 3.5.2 The cleaning process by the current cycle

Figure 3.5.3 High and low frequency currents in pulsing

Figure 3.6.1 DC HF output circuit

Figure 3.7.1 The graph

Figure 3.7.2 Four AC wave forms

Figure 3.7.2.2 Effect of Independent AC amperage control on weld penetration and weld bead profile

Figure 3.7.2.3 Effect of variation in AC frequency on the weld profile and penetration

Figure 3.7.2.4 Provides an example of a weld done at 150 Hz and 40 Hz

Figure 3.7.2.5 Weld profile as a result of extended EN of the cycle

Figure 3.7.2.6 Weld profile as a result of reduced EN cycle

Figure 3.7.4.1 A schematic drawing of single-phase DC power source with SCR bridge control

Figure 3.7.6.1 Schematic diagram of a DC generator

Figure 3.7.6.2 DC excitation circuit

Figure 3.9.1 Gas flow meters (A) shows the tube type flow meter, and the bottom (B) has a gauge type flow meter both calibrated in L/min

Figure 3.10.1 A typical manual welding torch, note the water cooling, gas supply and tungsten electrode assembly

Figure 3.10.2 Various nozzles types and sizes

Figure 3.10.3 A gas lens, with mesh, and holding circlip

Figure 3.10.4 An assortment of manual welding GTAW torch components

Figure 3.11.1 Electrode tips

Figure 3.11.2.1 The tip angle 60°, note the depth of the deeper penetration and the shape and depth of the HAZ

Figure 3.11.2.2 The tip angle 30°, note the depth of the shallower penetration and the shape of the HAZ

Figure 3.11.2.3 The tip angle 15°, note the depth of the shallowest penetration and the shape of the HAZ

Читать дальше