| Power tower CSP projects |

Thermal energy storage (TES) |

Thermal energy storage capacity |

Storage description and material |

| Atacama-1 |

2-tank direct |

17.5 hours |

Molten salt |

| Aurora Solar Energy Project |

2-tank direct |

8 hours |

Molten salt |

| Copiapó |

2-tank direct |

14 hours |

Molten salt |

| Crescent Dunes Solar Energy Project (Tonopah) |

2-tank direct |

10 hours |

Molten salt |

| Dahan Power Plant |

Other |

1 hour |

Saturated steam/oil |

| DEWA CSP Tower Project |

2-tank direct |

15 hours |

Molten salt |

| Gemasolar Thermosolar Plant (Gemasolar) |

2-tank direct |

15 hour(s) |

Molten salt |

| Golden Tower 100MW Molten Salt project |

2-tank direct |

8 hours |

Molten salt |

| Golmud |

2-tank direct |

15 hours |

Molten salt |

| Greenway CSP Mersin Tower Plant |

Other |

4 MW/h |

Molten salt |

| Hami 50 MW CSP Project |

2-tank direct |

8 hours |

Molten salt |

| Huanghe Qinghai Delingha 135 MW DSG Tower CSP Project |

2-tank indirect |

3.7 hours |

Molten salt |

| Jemalong Solar Thermal Station |

2-tank direct |

3 hours |

Liquid sodium |

| Jülich Solar Tower |

Other |

1.5 hours |

Ceramic heat sink |

| Khi Solar One |

Other |

2 hours |

Saturated steam |

| Likana Solar Energy Project |

2-tank direct |

13 hours |

Molten salt |

| MINOS |

2-tank indirect |

5 hours |

Molten salt 60% sodium nitrate and 40% potassium nitrate |

| NOOR III |

2-tank direct |

7 hours |

Molten salt |

| Qinghai Gonghe 50 MW CSP Plant |

2-tank direct |

6 hours |

Molten salt |

| Redstone Solar Thermal Power Plant |

2-tank direct |

12 hours |

Molten salt |

| Shangyi 50MW DSG Tower CSP project |

2-tank indirect |

4 hours |

Molten salt |

| Shouhang Dunhuang 10 MW Phase I |

2-tank direct |

15 hours |

Molten salt |

| Shouhang Dunhuang 100 MW Phase II |

2-tank direct |

11 hours |

Molten salt |

| SUPCON Delingha 10 MW Tower |

2-tank direct |

2 hours |

Molten salt |

| SUPCON Delingha 50 MW Tower |

2-tank direct |

7 hours |

Molten salt |

| Tamarugal Solar Energy Project |

2-tank direct |

13 hours |

Molten salt |

| Yumen 100MW Molten Salt Tower CSP project |

2-tank direct |

10 hours |

Molten salt |

| Yumen 50MW Molten Salt Tower CSP project |

2-tank direct |

6 hours |

Molten salt |

Gujarat Solar One (Technology Parabolic Trough), a commercial plant developed by Cargo Solar Power, operates at a temperature range of 293ºC-393ºC and 9 hours storage capacity involving molten salt. Extresol-1, a commercial plant in Spain, developed by ACS/Cobra Group, uses storage system of capacity 7.5 hour(s). The storage material is a combination of various materials with 60% sodium nitrate and 40% potassium nitrate. Similarly, a large number of concentrating solar power (CSP) projects with all receiver concepts (except for dish system) use an active two-tank indirect storage system. The summary is listed in Tables 1.1, 1.2and 1.3.

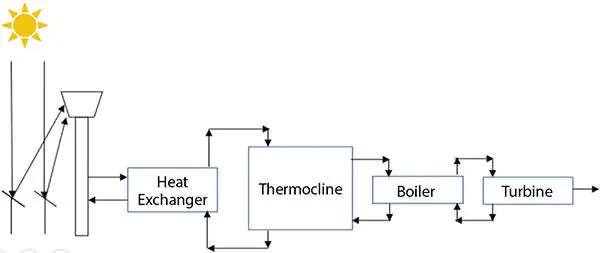

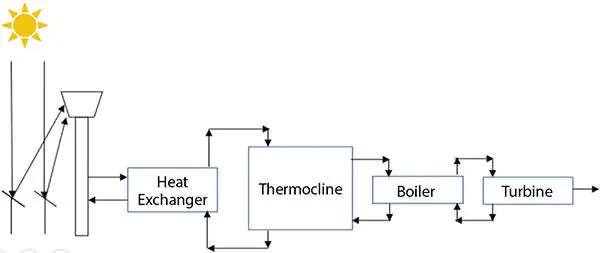

1.3.2 Active Single-Tank Thermocline

In a thermocline system, a single tank is used where warm fluid is above colder fluid. These kinds of systems are less expensive than two-tank systems [ Figure 1.8]. The heat loss is more in such systems as the hot and cold fluids are in direct contact. The hot and cold temperature regions are separated by a temperature gradient resulting in a thermocline. The density difference in the fluid thermally stratify the fluid in the tank. Buoyancy effects create thermal stratification of the fluid within the tank, which helps to stabilize and maintain the thermocline. Van Lew et al . (2011), Bayón and Rojas (2014), and Biencinto et al . (2014) carried out theoretical and experimental work on thermocline energy storage system for CSP plants.

Figure 1.8 Active single tank thermocline thermal energy storage.

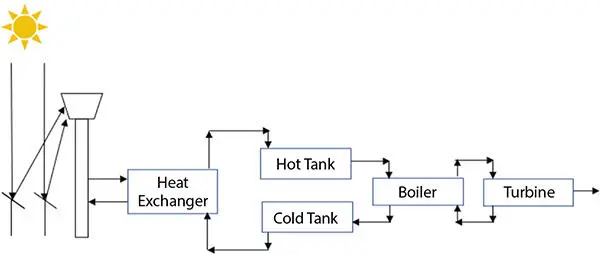

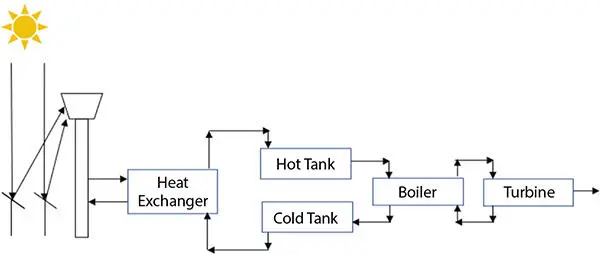

Figure 1.9 Active two-tank indirect thermal energy storage.

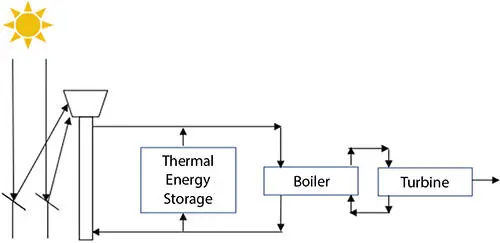

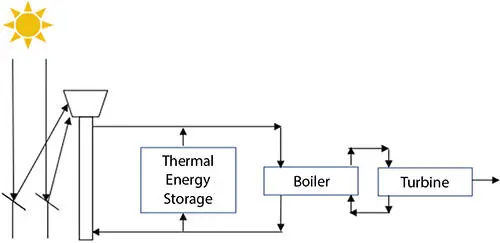

Figure 1.10 Passive thermal energy storage.

High-temperature HTF flows into the top of the thermocline and leaves the bottom at low temperature. The thermocline moves downward and adds thermal energy to the system for storage. The thermocline moves upward and removes thermal energy from the system to generate steam and electricity if the flow is reversed. Puerto Errado 2 Thermosolar [see Table 1.2] operated by Novatec Solar España uses linear Fresnel reflector system currently operational in Calasparra, Spain, and has implemented a single-tank thermocline thermal energy storage system. This plant is operated at a temperature range of 140ºC-270ºC. Other plants also use this type of thermal systems and are listed in Tables 1.1, 1.2and 1.3. Active two tank indirect thermal energy storage is also given in Figure 1.9and passive type thermal energy storage in built with solar tower technology is given in Figure 1.10.

1.3.3 Other TES Systems

1.3.3.1 Packed-Bed Storage System

Other types of thermal energy storage system include packed-bed and passive system. Only power plants use a packed-bed system as the storage method is Airlight Energy Ait-Baha Pilot Plant. This plant uses Parabolic Trough Technology at temperature range of 270ºC-570ºC with 5 hours storage capacity.

1.3.3.2 Passive Thermal Storage System

In the passive type TES systems, thermal storage material is fixed and it does not flow, which is in contrast to the active system. The thermal storage material is used only to store thermal energy which can be transferred to and from the heat transfer fluid via thermal charging and discharging. A passive-type thermal storage system can be a solid material (example: concrete), fluid (example: water) or phase change material (example: PCM). In such systems, the heat transfer fluid transfer energy to the thermal storage material where the material stores energy which can be further transferred to the heat transfer fluid. Such systems have not been integrated in solar thermal power plants till date. The works on passive thermal energy storage system are on the laboratory and fundamental level. A good number of research works can be found in literature on the passive thermal energy storage system.

1.3.4 Types of Thermal Energy Storage (TES)

There are three types of TES mechanisms that can be applied to CSP and other applications: sensible energy storage, latent energy storage and thermochemical energy storage. An overview of these technical concepts and their states of development are presented below.

Читать дальше