Table 2.2 Basic properties of NEO [2,6–8, 13, 21, 26].

Source: Based on Rakesh and Thomas [2]; Wilhelm et al. [6]; Kumar et al. [13]; Maharana et al. [26].

| Properties Oils |

Kinematic viscosity at 40 °C (cSt) |

Flash point (°C) |

Acid value (mg KOH/g) |

AC BDV (kV) |

Pour point (°C) |

| Jatropha oil |

33.8 |

260 |

0.06 |

73 |

−3 |

| Crude Pongamia oil |

32 |

250 |

1.3 |

87.5 |

−25 |

| Pongamia oil Methyl Ester |

12 |

284 |

0.9 |

82 |

−1 |

| Rapeseed oil |

43 |

325 |

0.03 |

73 |

−18 |

| Biovolt A (mineraltec) |

36.1 |

312 |

0.05 |

55 |

−21 |

| Soya oil |

33.1 |

318 |

0.08 |

42 |

−12 |

| Rice oil |

32.4 |

318 |

0.04 |

37 |

−15 |

| Sunflower oil |

38 |

312 |

0.06 |

37 |

−6 |

| Coconut oil |

25.7 |

298 |

0.005 – 0.05 |

35 |

23 |

| Neem oil |

108.79 |

288 |

— |

43 |

— |

| Mustard oil |

95.74 |

289 |

— |

41.6 |

— |

| Punna oil |

129.66 |

280 |

— |

42.3 |

— |

| Castor oil |

155.71 |

280 |

— |

31 |

— |

| Palm oil |

5.06 |

186 |

0.005 |

81 |

−32.5 |

| Mineral oil |

8.13 |

146 |

0.01 |

35 |

−40 |

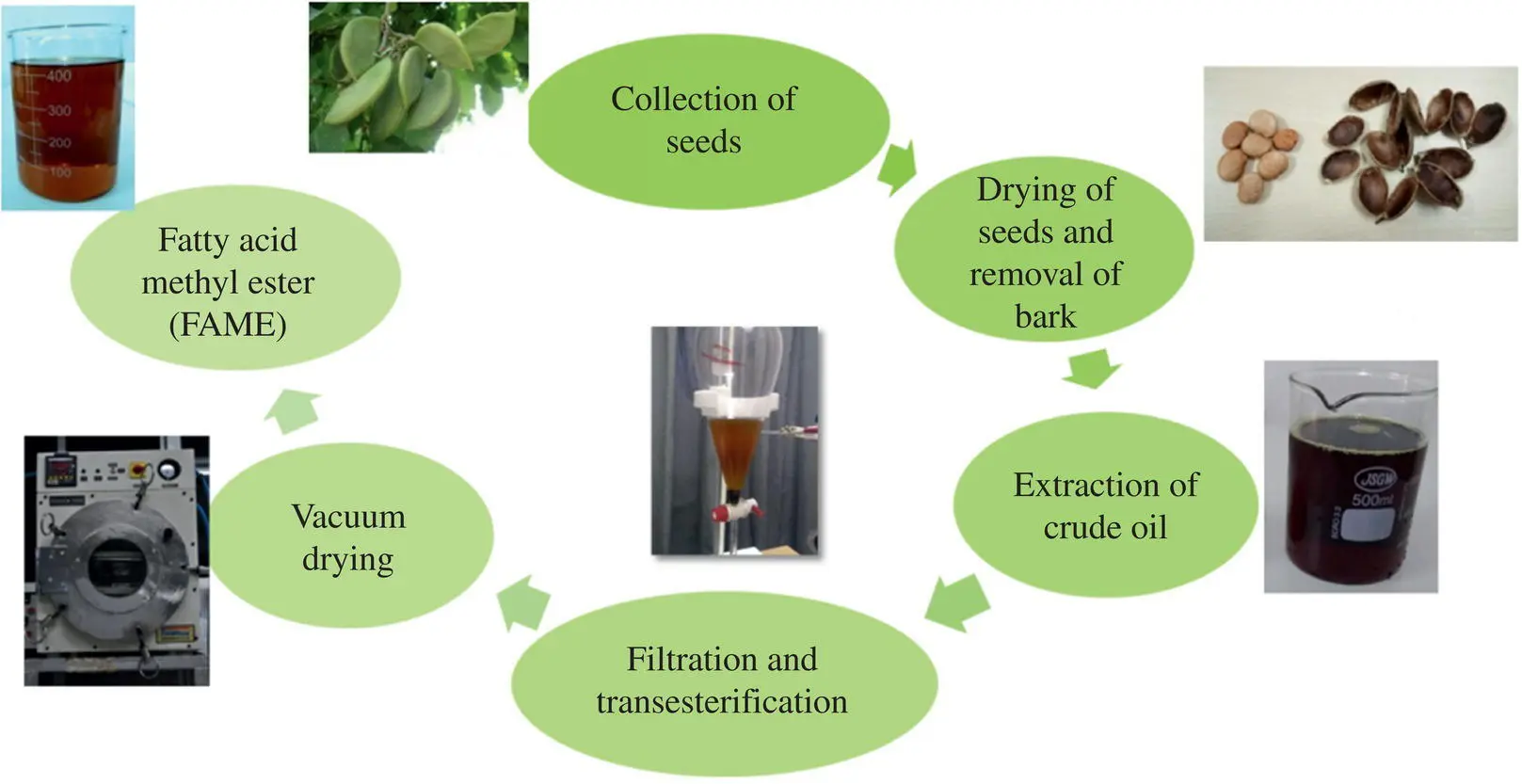

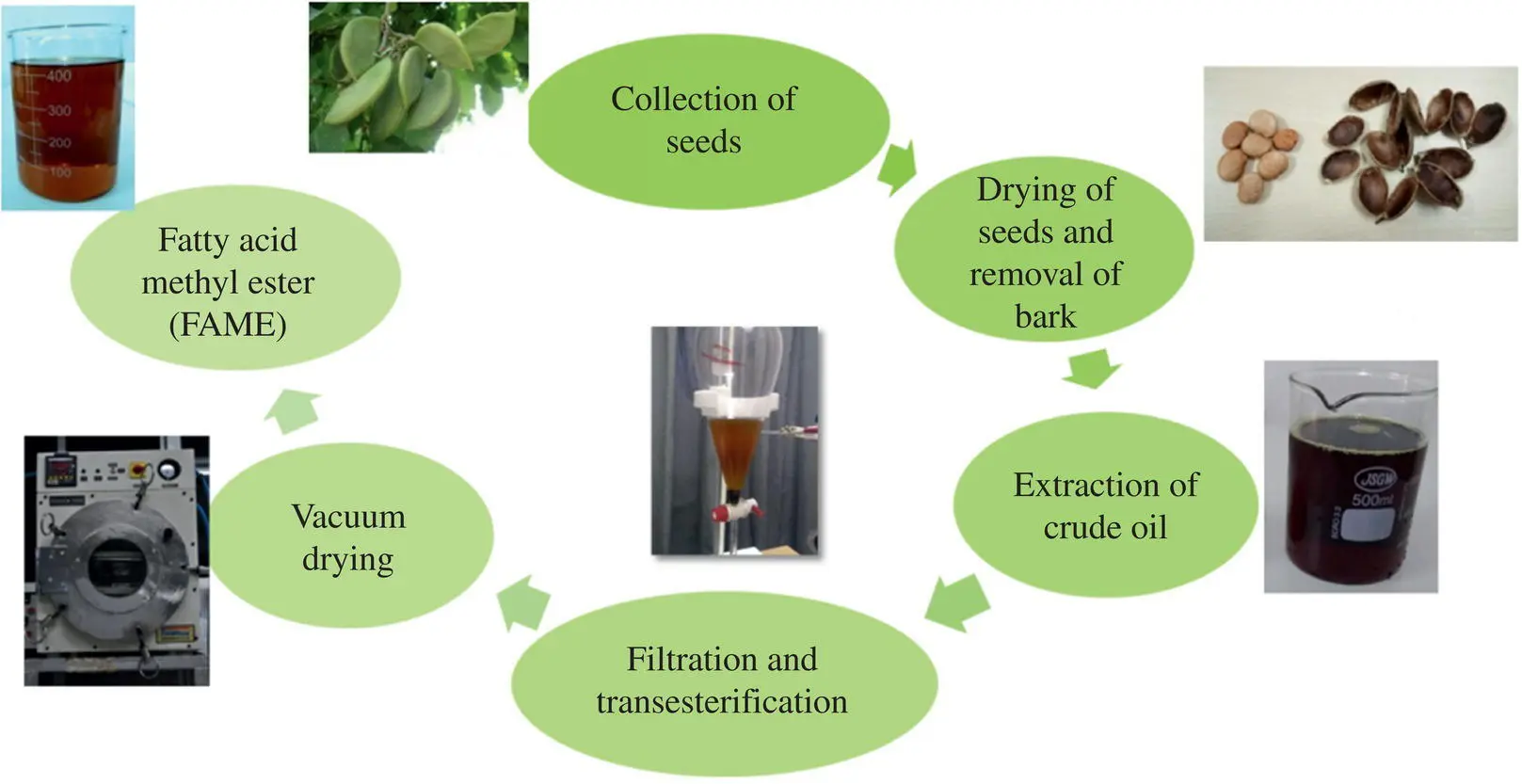

Figure 2.2 Processing of natural esters from seeds.

2.3.1.1 Mechanical Extraction

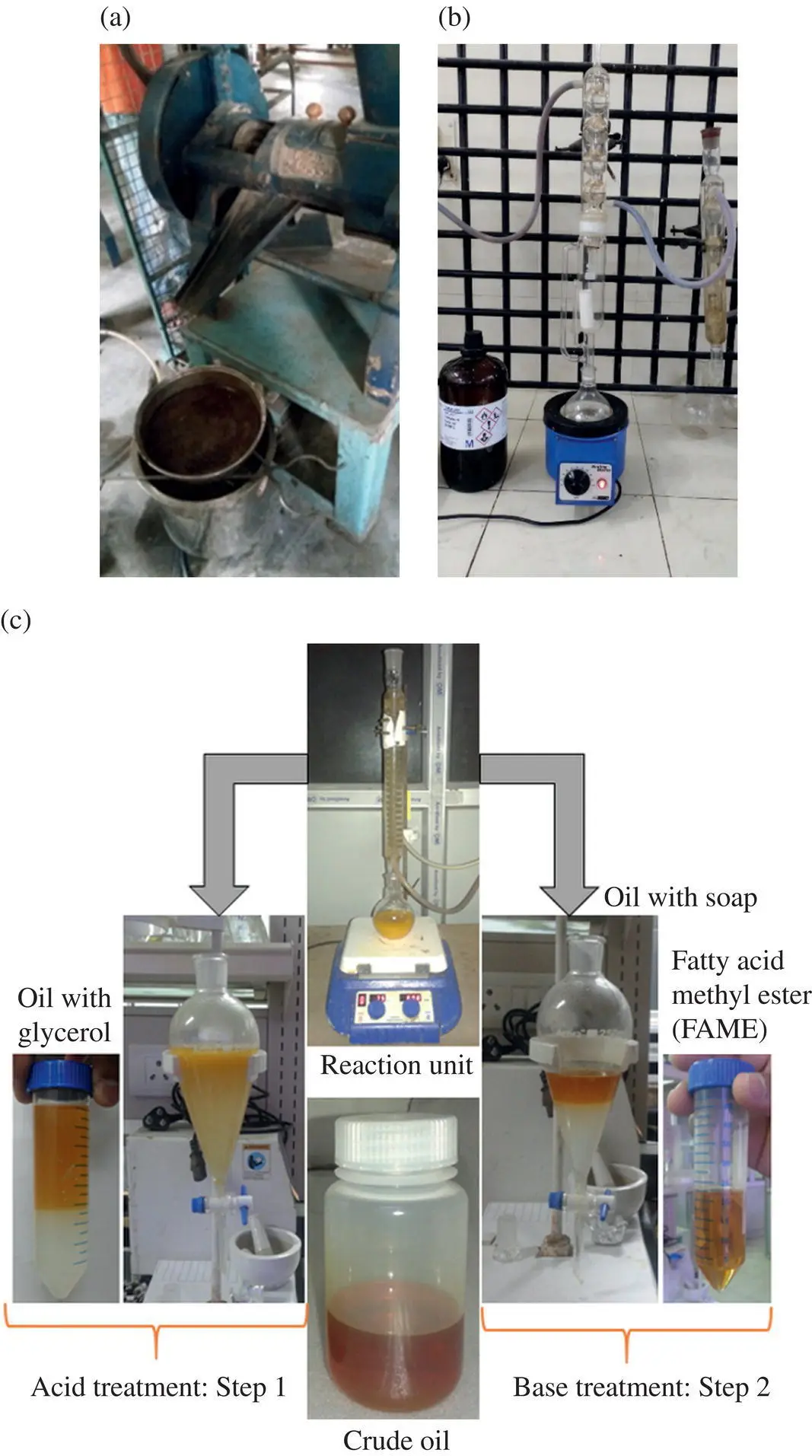

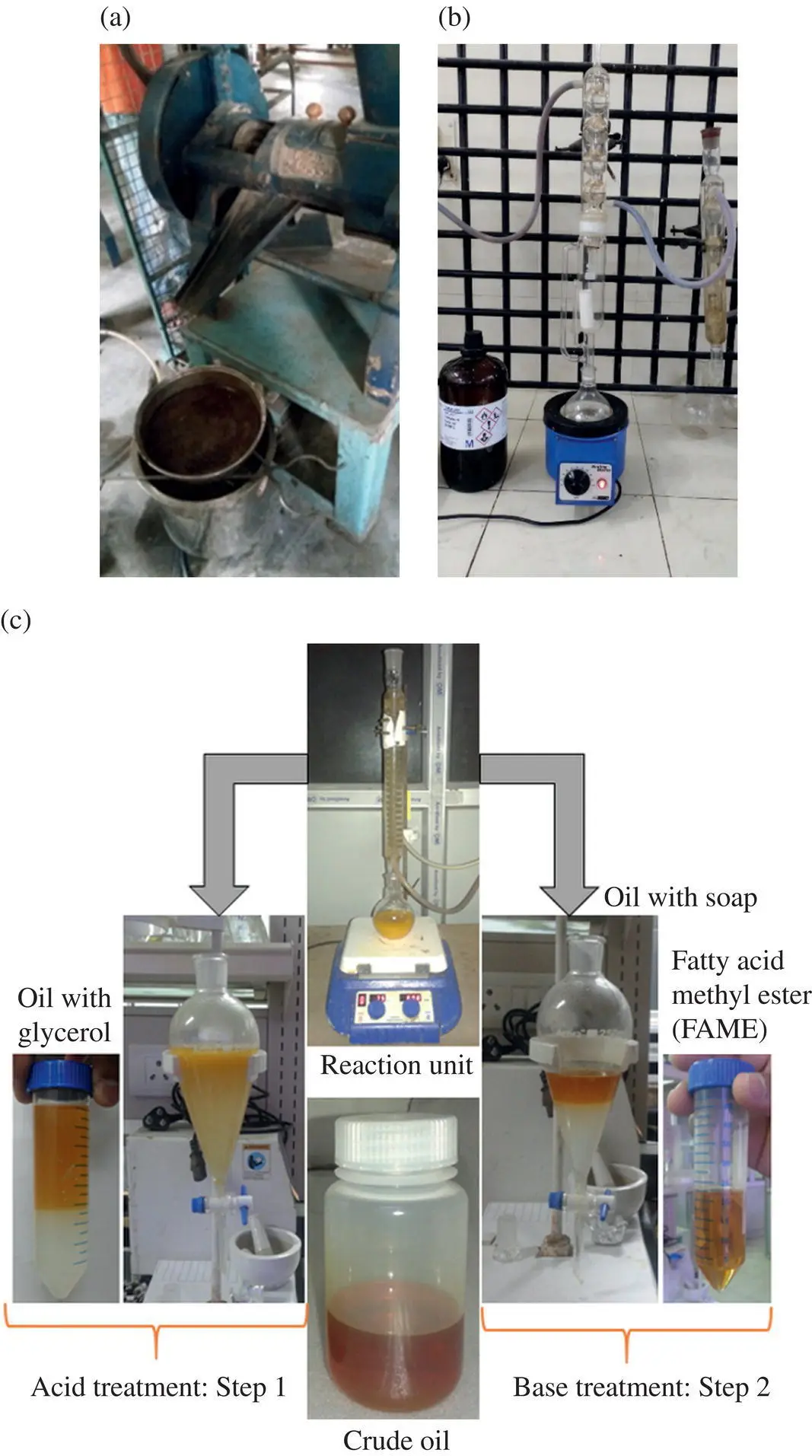

Mechanical extraction is a conventional yet widely used crude oil extraction process followed for biological oil production. This method of extraction is suitable for industrial and large‐scale crude oil production. The treated seeds are permitted to flow into the mechanical extruder and allowed to crush the seeds through a twin screw extruder as seen in Figure 2.3a. In this process, the crude oil is collected at the bottom of the extruder whereas the by‐products are separated out.

2.3.1.2 Chemical Extraction

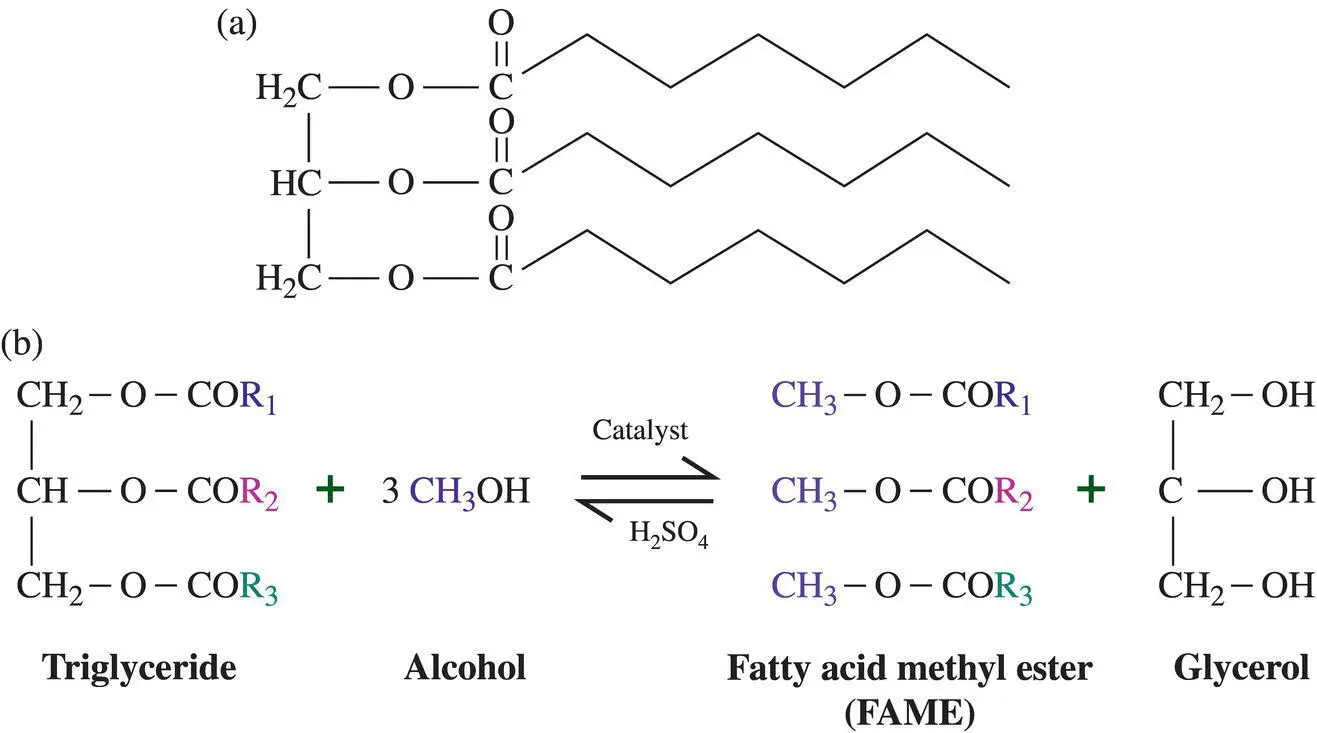

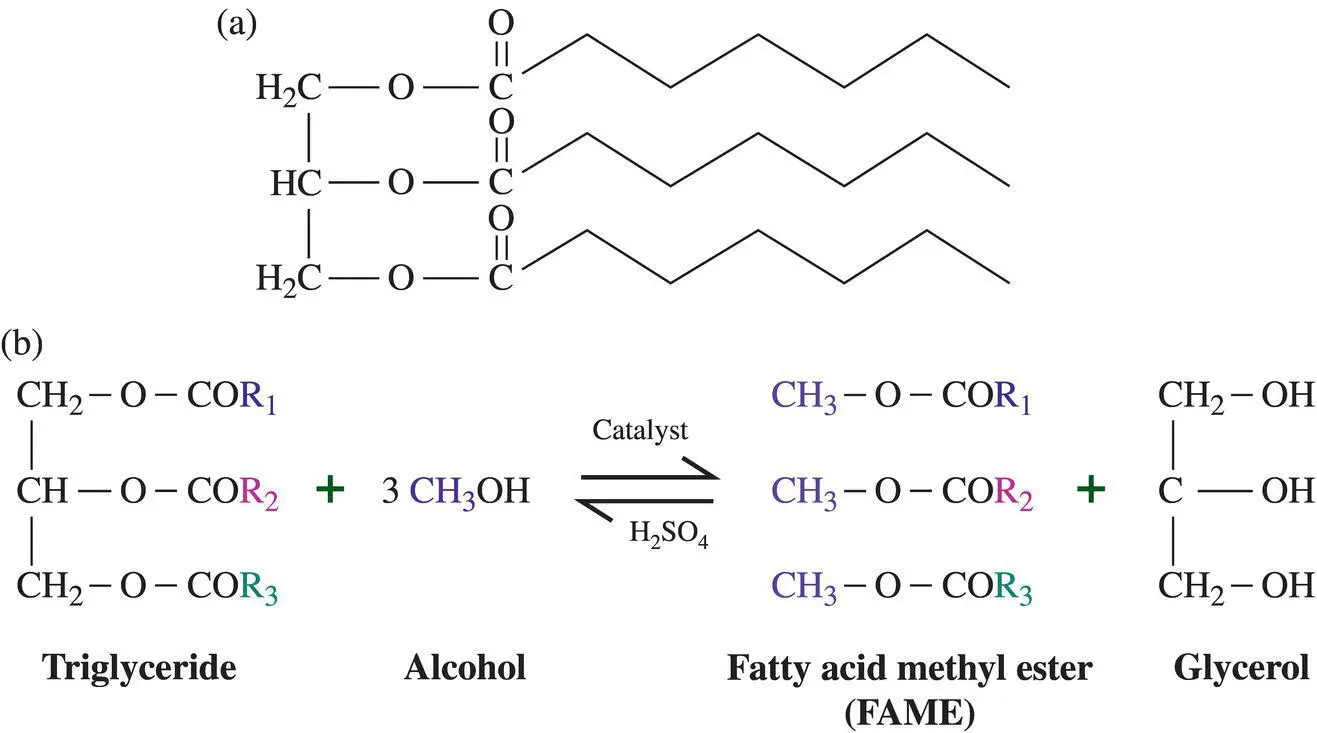

Initially, the treated biological seeds are collected and crushed using a grinder and converted into fine tiny particles. Next, the fine amorphous particles of seeds are mixed with the petroleum benzene. The solvent is allowed to stabilize for 24 hours and the yield of oil is collected, which is around 25–30% [47]. The collected oil from the solvent is treated using rotavapor for the removal of moisture as seen in Figure 2.3b. Thereafter, the crude oil is collected through filtration. The extracted crude oil has the rich content of triglycerides, which makes the crude ester highly viscous and of weak flowability. The triglyceride configuration is formed by condensation of three hydroxyl groups with carboxyl groups of three fatty acids, as shown in Figure 2.4a. Since the extracted crude oil from the treated seeds through mechanical and chemical treatment has a high viscosity and acidity content, it is not suitable as liquid dielectric. Therefore, the transesterification process is followed for the crude oil for suitable liquid dielectrics.

2.3.2 Transesterification

Crude vegetable oil does not meet the dielectric liquid standard, as per IEEE C.57.147 and ASTM D6871 [48] for industrial application. Hence, the extracted crude biological oil has to undergo the transesterification process to meet the standard. In this process, moisture removal is the primary step where the crude oil sample is allowed to heat up to 100–130 °C in an oven for one hour. In order to ascertain the number of steps required for the transesterification process, free fatty acid (FFA) measurement is carried out for the dried oil. FFA is measured as per ASTM D5555 [49] using titration method considering 0.1N potassium hydroxide (KOH) solution. It is observed that if the measured FFA is more than 1%, then two‐step transesterification is required to obtain the fatty acid methyl ester (FAME), which is the final refined form of the oil. Transesterification is the procedure that comprises the making of FAME from the crude oil to lessen the acid and viscosity values and make those similar to that of MO for transformer application. The transesterification reaction process is given in Figure 2.4b. The alcohol reacts with the fatty acids to form three molecules of mono‐alkyl ester and crude glycerol.

Figure 2.3 (a) Mechanical extraction. (b) Chemical extraction. (c) Transesterification setup.

Figure 2.4 (a) Triglyceride structure. (b) Formation of fatty acid methyl ester.

A two‐step transesterification reaction unit, comprising acid and base esterification, is presented in Figure 2.3c. In this process, the FFA is reduced using acid treatment or acid esterification technique. During the acid treatment, sulphuric acid (H 2SO 4) is used as a catalyst. The experiment is carried out using a round bottom flask with reflux condenser. The temperature of the reaction is maintained and controlled using a magnetic stirring hotplate. The separating funnel is used to separate the glycerol out from the crude oil. During the transesterification, a standard molar ratio mixture of 6:1 is chosen for methanol to crude biological oil, respectively. When the temperature of the mixture reaches 60 °C, 1 vol.% of H 2SO 4is poured into the round bottom flask as a catalyst [50, 51]. The solution is poured into the flask and constantly stirred at 600 rpm for a session of two hours with the help of a magnetic stirrer. Then, the prepared mixture is poured into the separating funnel and allowed to stabilize for 24 hours for the acid separation. Due to the variation of density from oil to water, the water precipitates at the lower part, the lower fatty acid‐based oil forms at the middle part, and the mixture of sulphuric acid and methanol lies in the top part. The settled water is removed out using a drain tap attached to the separating funnel and finally the lower FFA oil is collected. The calculated FFA value is the indicator of the decrement of acidity percentage of the crude oil.

If the FFA value lies above 1%, it has to be further treated using base transesterification, in which the mixture obtained from the earlier step is shifted to a round bottom flask and heated up to a temperature of 60 °C. The same molar ratio from the acid transesterification is considered and an adequate amount of base catalyst, that is KOH (1% by wt.), is poured into the mixture. Thereafter, the same solution is heated and stirred simultaneously for three hours. Then, oil separation technique is followed by keeping the solution in the separating funnel for 24 hours for the settlement of high‐density glycerol. Top layers are formed in the separating funnel, the upper is FAME and the bottom layer is the glycerol. The solution is continuously washed by using hot distilled water that removes the unwanted impurities. It is then centrifuged at 6000 rpm for 10–15 minutes to obtain the FAME. Due to the difference in density, the low‐density oil floats at the top of the centrifuge tube while the unwanted glycerol settles at the bottom. Thus, the FAME can be separated easily from the top.

Читать дальше