2.2 Significant Natural Ester Liquids

The liquid insulation in a power/distribution transformer is used for various purposes:

1 A cooling agent – During the operational time, the core and windings get heated, so the liquid insulation helps to transfer the heat outside.

2 An insulating agent – The liquid insulation helps to insulate the different conducting parts of the transformer.

Owing to the concerns regarding environment and sustainability, researchers started looking for other alternate options to the conventional MO [27]. NEOs are a perfect substitute to the conventional MO and other synthetic liquids. These oils are completely biodegradable and nontoxic in nature. However, the downside of using these oils is that they have high pour point, higher viscosity, and oxidize easily. Some of these oils have greater content of unsaturated fatty acids which lowers the viscosity and aids in faster oxidation. Whereas, some others consist of high percentage of saturated acids, which improves oxidation stability. Thus, the oil chosen should be such that it provides a finest balance for smooth operation of an apparatus. Pongamia and jatropha oils are chosen for discussion because of their nonedible nature and they serve as potential substitutes for the conventional MO. Along with them, some other NEOs are also briefly described below.

Soybean oil is one of the most prominent NEO, which is being used as an insulating agent in transformers [28, 29]. It is extracted from soybean seeds and mainly consists of unsaturated fatty acids like the polyunsaturated α‐linolenic acid, linoleic acid, and monounsaturated oleic acid [30]. This oil has lower oxidation stability and its viscosity is also on the higher side. This oil polymerizes easily contributing to even higher levels of viscosity. With the addition of antioxidants, it shows relatively better oxidation stability and lower viscosity [31]. Efforts are carried out to obtain a better soybean oil with enhanced properties. This oil shows better oxidation stability when used with antioxidants like citric acid and the tert‐butyl hydroquinone [31]. The oil is also winterized to lower the pour point to be suitable for use in colder climates. Studies have shown that some of the properties of soybean oil are superior to that of MO [32].

2.2.2 Pongamia Pinnata Oil

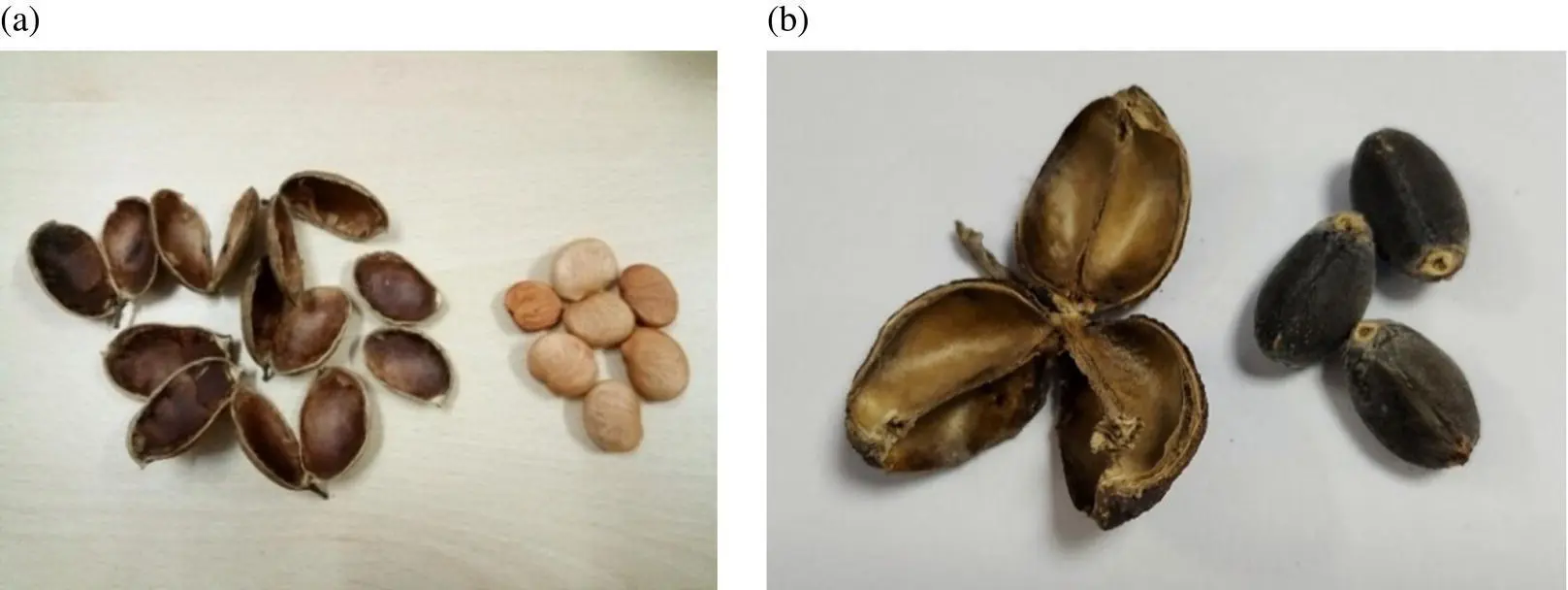

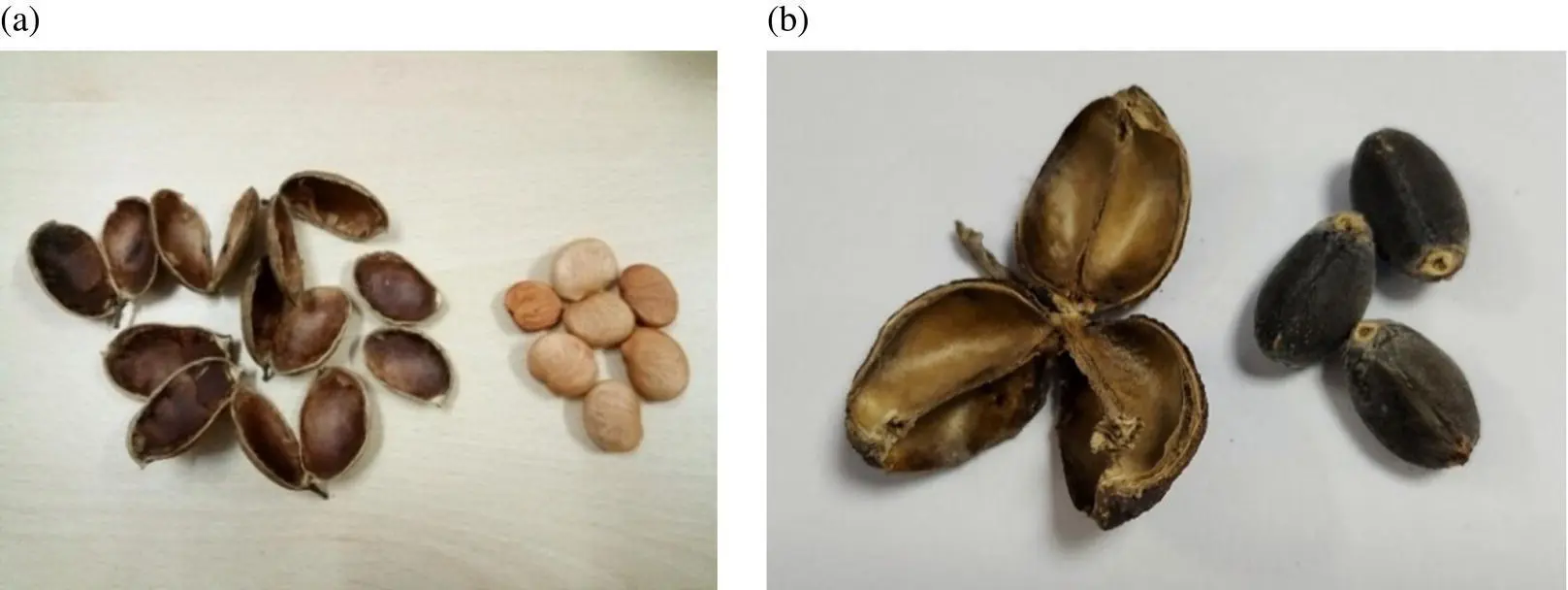

Pongamia pinnata oil or commonly known as the karanji oil belongs to the species of family Leguminosae and genus Pongamia. This plant is native to the tropical and temperate regions including parts of India, China, Japan, Malaysia, and Australia. This plant is unaffected by drought and grows up to 20 m in height with soft, shiny leaves. This plant is also semi‐deciduous and leguminous tree, and has the property of nitrogen fixing. This plant starts to flower and seeds are obtained, in around a time frame of five years. The inspection article of Germplasm Resources Information Network United States Department of Agriculture shows that 9–90 kg Pongamia pinnata seeds can be produced from a single tree per year [33]. The prospective yield per hectare is around 900–9000 kg/ha. As per available data, Pongamia oil has got a potential of 135 000 million tons per year and only 6% is being exploited. Traditionally, this plant has been used in Indian and south‐east Asian regions as a source of Ayurvedic medicines for skin diseases, rheumatism, animal fodder, green manure, and timber. In recent times, Pongamia pinnata has been accepted as a practicable source of nonedible oil for the biofuel industry [34]. A sample of Pongamia pinnata seeds is shown in Figure 2.1a. The pongamia oil has higher flash point and breakdown voltages than the MO, but a comparable viscosity.

2.2.3 Jatropha Curcas Oil

Jatropha Curcas oil is another type of NEO, which is extracted from the seeds of the jatropha plant. This oil is majorly used in the fields where biodiesel is required. It is a product from a renewable resource and it is environment‐friendly, aids in decreasing greenhouse gas emissions, and is able to combat the ever‐growing energy emergency [35]. The nonedible nature of this oil is the most important advantage as it can be used for the profit of humankind without distressing the food consuming population. This plant, therefore, does not need very much fertile land to be grown as it is not for human consumption purpose. Also, the rainfall requirement of the jatropha plants is much lesser than the other seed crops like sunflower, canola, and soybeans [36]. The jatropha seeds are shown in Figure 2.1b. The basic component of crude Jatropha Curcas oil is triglyceride or triacylglycerol. The jatropha oil also has higher BDV and flash point than the conventional MO. However, the viscosity of jatropha is higher due to its higher molecular mass.

Palm oil is derived from the palm tree fruit. This oil has a higher percentage of saturated fat content, thus forms a jelly like substance at room temperature with high viscosity [37]. The palm oil is mostly available from plantations in Indonesia and Malaysia. The basic component present in this oil is triacylglycerol and rest of the 95% is composed of glycerol with three fatty acids. Researches have shown that some of the electrical and thermophysical attributes of this insulating oil are better than the conventional MO [38]. Palm oil has an optimal balance of unsaturated and saturated fatty acids. It also has other benefits like a marginally higher flash point, higher BDV, and better PD properties. It is also biodegradable and nontoxic in nature as the oil is derived from palm fruit. Studies have shown that this oil can be used as an insulating agent in electrical apparatus [39–42]. The viscosity of palm oil is lower than most of the NEOs and somewhat lower than even MO, which gives it an added advantage [43]. A study conducted by some researchers showed the effect of moisture content on BDV and characteristics of palm oil‐based insulating oils by FTIR spectroscopy and compared with MO [44]. They showed that the moisture saturation limits of palm oil are higher than that of MO.

Figure 2.1 (a) Pongamia seeds, (b) Jatropha seeds.

2.2.5 Rapeseed Oil (Canola Oil)

The rapeseed oil or canola oil is extracted from the crude rapeseed oil after three refinement procedures, which are alkaline refinement, vacuum distillation, and bleaching [45, 46]. The basic attributes of the refined oil are shown in Table 2.2. The refined form of rapeseed oil exhibits lighter color, lower acid value, and enhanced electrical properties when compared with the crude form of the oil. The flash point of the rapeseed oil is above 300 °C, which is nearly twofold the flash point value of the conventional MO used in transformers. The dipolar characteristic of ester molecules produces higher values of dielectric permittivity ( ε r), and dielectric dissipation factor (tan δ ) of the insulating rapeseed oil than transformer MO.

2.3 Processing and Pretreatment

The potential methyl ester‐rich biological seeds such as Pongamia pinnata, Jatropha Curcas, etc., are the primary feedstock for the preparation of natural ester. Therefore, before processing the seeds for the extraction of the crude oil, pretreatment is required. This process involves a series of steps mentioned in Figure 2.2.

From Figure 2.2, it is seen that the biological seeds are collected when they mature. Thereafter, the thick cover on the oil nut is removed by peeling. Once the seeds are peeled off, they are allowed to undergo heat treatment for drying. The drying process is of two types; one is the natural method of drying by exposing the seeds to sun light, and another is the laboratory method using the heating ovens. After that, the treated seeds are dried completely, and removal of dead seeds and solid impurities are carried out through separation technique. Once the separation is over, the seeds are now ready for extraction of crude oil.

Читать дальше