C. Anandharamakrishnan - 3D Printing of Foods

Здесь есть возможность читать онлайн «C. Anandharamakrishnan - 3D Printing of Foods» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:3D Printing of Foods

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:3 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 60

- 1

- 2

- 3

- 4

- 5

3D Printing of Foods: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «3D Printing of Foods»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Explore the fascinating realm of 3D food printing and its applications 3D Printing of Foods

3D Printing of Foods

3D Printing of Foods

3D Printing of Foods — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «3D Printing of Foods», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

Only a few studies were reported on revealing the complexity involved in the 3D printing of fibres. Lille et al. (2018) conducted a study on correlating the material supply for the development of novel 3D structures with a food formula rich in fibre and protein with reduced‐fat and sugars. The ingredients of the printing mixture composed of starch, nanocellulose fibres and milk powder. These ingredients were tested individually as well as in combination for obtaining stable 3D structures after printing. Considering the printability of fibres, the gel matrix was reinforced with cellulose nanofibers (CNF). Printing of fibres showed that there was a discontinuous material flow of the CNF gel system that seems to block the printing nozzle due to its larger fibre particles, causing phase separation and material flocculation (Lille et al. 2018). This study provides a comparative assessment of ingredients and showed that 3D printing of fibres was quite difficult than that of starch and protein‐based food systems. Further, the study highlights a key challenge associated with the printing of fibre‐rich food systems providing an overall idea of the applicability of diverse food materials for 3D printing.

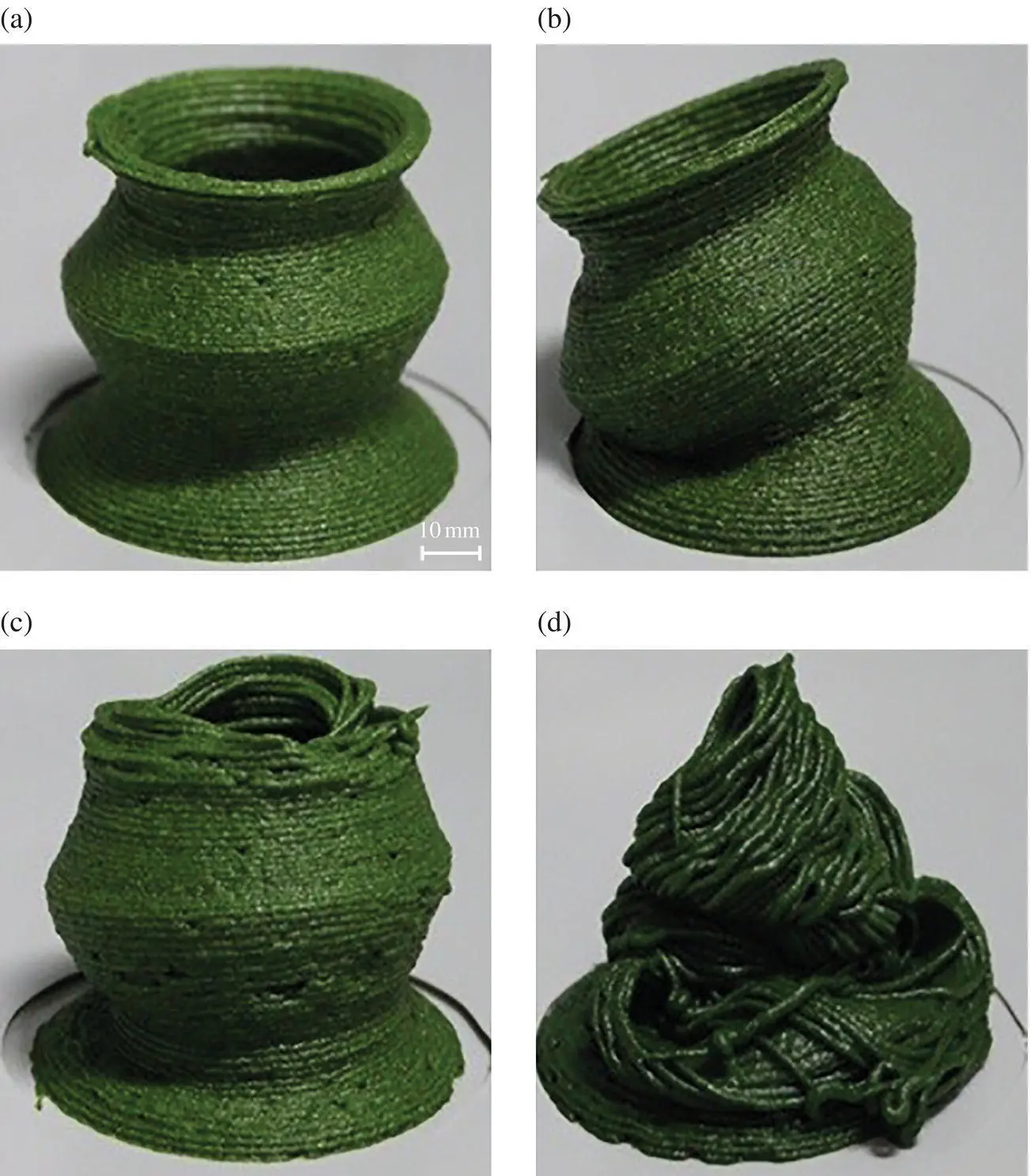

In another study, a fibrous cellular material freeze‐dried spinach was characterized for microstructural composition and the suitability of which as food ink was assessed for 3D printing (Lee et al. 2019). The effect of particle size on printing performance was investigated and the addition of 10% (w/w) xanthan gum showed a promising result in retarding the swelling effects of spinach powder by increasing its water holding capacity. Here, printability was demonstrated by the shear modulus and the extrudability. Results showed that the mechanical stability of the printed structures was improved with the higher particle size of spinach powder ( Figure 3.5). Further, this study emphasized particle size as an important variable in assessing the printability of the food ink. However, the study was not focused on revealing the science behind the printing of fibrous material. In another study, researchers have made successful attempts in the printing of fibre and protein‐rich indigenous composite flour (Krishnaraj et al. 2019). Here, natively printable composite flour composed of barnyard millet, green gram, fried gram, and ajwain seeds were subjected for 3D printing to develop a nutritious snack for personalized nutrition. The formulated composite flour contains a concoction of macronutrients with 11% and 18% of fibre and protein, respectively. The physicochemical composition of the indigenous native flour was responsible for its printability. The presence of a small fraction of lipid in the millets was adequate for aiding the smooth flow of printing material supply as it results in the plasticizing effect that eases the material flowability through the printing nozzle (Krishnaraj et al. 2019). Further, the ingredient composition of the formulated material supply well assists in overcoming other undesirable effects of agglomeration and flocculation of fibre during printing.

Except for handful of works, there is only less information available on printing characteristics of fibre‐rich material supply. With the available literature, it was evident that the printability of the dense nature of fibrous material could be correlated with physical attributes such as particle size, surface corrugation, and material density (Nachal et al. 2019). Certain pre‐processing was adequate for fibre‐rich material in order to make it suitable for 3D printing applications. This includes size reduction and particle breakdown with the regulation of total solids content that in turn determines the printing quality of fibre‐rich material supply. Still, the biophysics underlying the printability of fibres has not yet been well explored. More studies must be taken forward for exploring the inherent potential benefits of 3D printing of fibre‐rich material supplies.

Figure 3.5 Effect of particle size on 3D printing of fibrous spinach powder (a) 307 μm, (b) 259 μm, (c) 172 μm, (d) 50 μm.

Source: From Lee et al. (2019), Figure 03 [p. 05] / With permission of Elsevier. DOI‐ https://doi.org/10.1016/j.jfoodeng.2019.03.014.

3.4.5 Other Additives

Another diverse class of polysaccharides that are widely employed in the food industry are the hydrocolloids which form a group of long‐chain hydrophilic polymers (Li and Nie 2016). The presence of one or more hydroxyl groups rendered them water‐loving thereby forming a colloidal suspension when added into the food mixture. Hydrocolloids are derived either from plants/ seaweeds (xanthan gum, carrageenan, gum arabic, locust bean gum, guar gum, gellan gum, glucomannan, and pectin) or animal sources (gelatin, chitin, and chitosan) (Mehta et al. 2019) ( Table 3.1). They exhibit a varied range of functional property as they can act as thickeners, stabilizers, foaming agents, emulsifiers, and gelling agents that help in tailoring the rheology of food systems. Concerning 3D printing, hydrocolloids are commonly used as food additives for making the material supply attain a conducive consistency suitable for 3D printing by altering its flow and viscosity. Further many studies were reported on food hydrocolloids as reference material for 3D food printing. Kim et al. (2018) conducted a study on a comparative assessment of various hydrocolloids such as guar gum, gellan gum, xanthan gum, locust bean gum, hydroxypropyl methylcellulose (HPMC), methylcellulose (MC), and gelatin for their applicability in food printing. The study was performed for framing a classification system based on printability assessment. Among all the hydrocolloids considered for the study, MC was found to be capable of simulating the handling properties and deformation behaviour of foods and possess good mechanical stability which was comparable to most of the food systems with diverse viscosity. Thus, a classification system was made based on dimensional and storage stability as grade A to D with grade A more suitable for 3D printing that requires less extrudable force as with cheese. On the other hand, the latter category of grade D includes materials like cookie dough which requires more force to extrude out of the printing nozzle (Kim et al. 2018).

Table 3.1 Classification of food hydrocolloids.

| Origin | Examples of hydrocolloids |

|---|---|

| Plant | Gum arabic, basil seed gum, gum karaya, konjac, locust bean gum, flaxseed gum, guar gum, and starches |

| Animal | Chitin, chitosan, and gelatin |

| Seaweeds | Agar, alginate, xylan, carrageenan, and ulvan |

| Microbial | Gellan gum, tara gun, xanthan gum, dextran, curdlan, and pullulan |

| Synthetic | Carboxymethyl cellulose, methylcellulose, hydroxypropyl methylcellulose, and other cellulose derivatives |

In another study, Vancauwenberghe et al. (2017) developed a pectin‐based food stimulant for 3D printing applications. The study correlates the effect of the degree of methoxylation of pectin with a concentration of Ca 2+ions as a cross‐linking agent that aids in printability. Results showed that the formulation of food ink was greatly influenced by the density of the polymeric network and its degree of cross‐linking with Ca 2+ions. The addition of sugar to the food stimulant affects the viscoelastic behaviour and hence could be positively correlated with printability. As the incorporation of sugar dehydrates the polymeric matrix thereby enhancing the gelation mechanism with the formation of hydrogen bonds that would result in higher young’s modulus with firmer pectin‐based gel (Vancauwenberghe et al. 2017). Further, the study demonstrates the production of porous aerated 3D structure with the use of bovine serum albumin (BSA) and remains to be a base for future works for the development of food stimulants with added flavours and textures for food 3D printing.

Читать дальшеИнтервал:

Закладка:

Похожие книги на «3D Printing of Foods»

Представляем Вашему вниманию похожие книги на «3D Printing of Foods» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «3D Printing of Foods» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.