NITIN KUMAR - Thermal Food Engineering Operations

Здесь есть возможность читать онлайн «NITIN KUMAR - Thermal Food Engineering Operations» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Thermal Food Engineering Operations

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:5 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 100

- 1

- 2

- 3

- 4

- 5

Thermal Food Engineering Operations: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Thermal Food Engineering Operations»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

Presenting cutting-edge information on new and emerging food engineering processes,

, the first volume in the new series, “Bioprocessing in Food Science,” is an essential reference on the modeling, quality, safety, and technologies associated with food processing operations today.

This outstanding new volume:

Audience:

Thermal Food Engineering Operations — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Thermal Food Engineering Operations», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

1 Short waves 0.76-2 μm (near IR waves), temperature above 1000°C

2 Medium waves: 2-4 μm (medium IR waves), when the temperature is above 400 - 1000°C

3 Long waves: 4-1000 μm (far IR waves), when the temperature is below 400°C

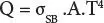

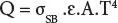

The working principle of infrared waves includes: IR energy is electromagnetic radiation emitted by hot objects (quartz lamb, quartz tubes, or metal body) by vibrations and rotation of molecules. When it is absorbed, the radiation provides up its energy to heat materials. An object is a “black-body”, if it absorbs (or emits) 100% of incident IR radiation. The quantity of heat emitted from a perfect radiator (blackbody) is expressed by Stefan-Boltzmann law equation:

Where Q is defined as the rate of heat emission, σ SBis the Stefan-Boltzmann constant, T is defined as the absolute temperature, and A is defined as the surface area.

When radiant heaters and food products are not perfect absorbers, the Stefan-Boltzmann equation was modified and the concept of “grey body” was found:

Where ɛ defined as the emissivity of the grey body (ranging from 0 to 1).

This property changes with the wavelength of emitted radiation and temperature of the grey body.

The heating level depends on the absorbed energy, which then rely on the composition of food and the radiation frequency.

Mathematically, the transfer of heat rate to food is expressed as,

Where T 1depicts the temperature of the emitter and T 2depicts the temperature of the absorber. Heat transfer rate relies on:

1 Surface temperatures of heating and receiving bodies or materials,

2 Surface characteristics of both bodies or materials,

3 Shapes of the emitting and receiving materials.

Quantities indicate infrared radiations are the perfect source of energy for heating purposes. They indicate the factors such as larger heat transfer capacity, heat penetration directly into the product, no heating of surrounding air, and fast process control. A perfect balance required for optimal heating between the body and surface heating is attained with IR. The parameters that are important to control to achieve optimal heating results are radiator temperature, infrared penetration characteristics, radiator efficiency, and infrared reflection or absorption properties.

1.3.1.2 Advantages of IR Heating

There are several advantages of IR over traditional heating techniques: [1].

Instant heat:Electric IR system forms heat instantly so there is no need for heat build-up.

Reduced operating costs:The energy can reach 50%, depending upon the insulation, types of construction, and other factors. Furthermore, operations maintenance is limited to the cleaning of reflectors and heat source changing.

Clean and safe:Operating IR is a low-risk task and there is no production of by-products.

Zone control:The IR energy is absorbed only where it is directed and does not propagate. Other advantages of IR are as follows:

1 Quick heating rate

2 Shorter residence time

3 Uniform drying temperature

4 A high degree of process control

5 Higher thermal efficiency

6 Cleaner work environment

7 Alternate source of energy

The utilization of IR technique in the food sector is still developing; many attempts are continuously growing for the development of IR technologies and the future research is focusing on process control and equipment design development, expanding the areas of applications of IR heating and understanding the interaction between heating process and product characteristics.

1.3.1.3 Applications of IR Heating

There are wide applications for IR (infrared radiation) which include medical, paper industries dye, automobile, and others. Table 1.1discusses the several application of IR heating [1]. In industrial applications, medium to long-range wavelengths seem to be beneficial, for all materials to be heated or dried give the largest absorption in the 3-10 mm region. Moreover, the applications in short waves are continuously evolving. Applications of IR are mostly within the area of food for drying and many other processes during the period from the 1950s to the 1970s from the Soviet Union, the United States, and the Eastern European countries. During the 1970s, much research was performed about industrial frying or meat products cooking and the utilization of near-infrared (NIR) techniques is initiated [28, 43]. In the 1970s and 1980s, several types of research were carried out to apply this technique in the sector of food, mostly at [Swedish Institute of Food and Biotechnology] and gained a set of knowledge. Recent work is experimental in nature and performed in Japan, Taiwan, and several other countries. Applications are mostly from areas such as dehydration, drying of vegetables, fish, rice, roasting of coffee, cocoa, and cereals, heating of floor, frying of meat, baking of pizza, biscuits, and bread, enzymes, and pathogens inactivation. Also, for thawing, blanching, sterilization, pasteurization of packing materials, and surface pasteurization, these techniques have been used.

The major effects on food involve the quick heating of food surfaces sealed in moisture and aroma compounds. Variation to components of food surfaces is equivalent to those that happen during baking.

1.3.2 Microwave Heating

1.3.2.1 Principal and Mechanism

With the increasing demand for healthy foods, there is a repeated effort given to enhance and optimize different processing techniques in food, to meet the expectations of consumers. With the advancement of emerging technologies, microwave energy has become an indispensable part of every household system. The use of microwave has expanded from heating and defrosting to thawing, blanching, sterilization, drying, etc., in food industries [20, 69]. Microwave is electromagnetic waves with a frequency which ranges from 300 Mhz to 300 GHz. Frequency of microwave used for domestic purposes is 2.45 GHz, whereas the frequency for industrial purposes is 915 MHz [8].

Table 1.1 Applications of Infrared heating: [1].

| Industry | Methods |

|---|---|

| Agriculture | Incubation and warming |

| Bottling | Drying |

| Glass | Drying, curing the varnish or paint on back—mirrors and tempering layers |

| Medical-applications | Incubation and warming |

| Environmental chambers | Heating |

| Food | Toasting, cooking, food warming, drying, broiling, and melting |

| Pharmaceutical | Drying water from powder—tablets |

| Metal treatment | Preheating—aluminum; steel |

| Paper | Laminating Calendaring—rolls Adhesive—labelsDrying water from—towels |

| Paint | Primer, topcoat alkyd, acrylic—steel panels, Drying—bicycles, vehicles bodies, aluminiumbodies |

| Textiles | Moisture elimination—carpets Latex and PVC backingMoisture elimination from dyes |

| Plastics | Laminating Annealing FormingEmbossing |

Microwave is a varying magnetic field that generates heat on interaction with, and absorption by, certain dielectric materials, and with the positioning of the direction of the electric field, the native thermal motion of the polarity molecule changes [26]. Water, the dominant polar molecule, consists of separated molecules of an oxygen atom with a negative charge and hydrogen atom with a positive charge which combinedly structure into an electric dipole. When these dipoles fluctuate swiftly back and forth from positive to negative in the direction of the electric field numerous times per second, these express reversals produce frictional heat. This implies that the polar molecules in food play a vital role in the heating performance of food in the microwave system. Due to this frictional rise in the temperature of the water, food components get heated up by convection and conduction. The loss factor dielectric constant of the food determines the depth of penetration of both microwaves and RF energy [49]. This also relies on the varying temperature and moisture concentration of the sample material plus the frequency of the electric field. Overall, with lesser frequency and loss factors, we get more depth of penetration. Energy distribution varies with food samples which also governs the depth of penetration of the microwave inside the food. As the food material to be heated in the microwave matches with the wavelength of the material, it becomes difficult to manage the heat uniformity of microwave heating which can be taken as a crucial constraint for industrial application of microwave heating. Thus, a central obligation for microwave energy application and microwave equipment in the food industry is the potential to accurately regulate heating uniformity. Microorganisms are not affected as a result of microwave radiation but are susceptible to the heat generated because of the radiation. Microwaves are likely to be a channel through ceramics, thermoplastics, and glass whereas they are absorbed by carbon and water; reflected by metals but conceivably transmitted using metal hollow tubes and on transiting amongst diverse materials get refracted like the visible light. Microwaves can also be focused on a beam [77].

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Thermal Food Engineering Operations»

Представляем Вашему вниманию похожие книги на «Thermal Food Engineering Operations» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Thermal Food Engineering Operations» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.