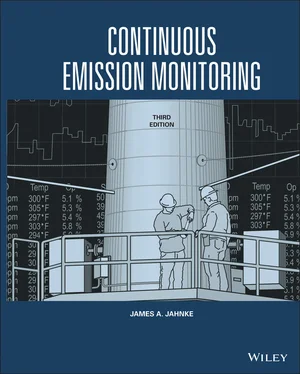

James A. Jahnke - Continuous Emission Monitoring

Здесь есть возможность читать онлайн «James A. Jahnke - Continuous Emission Monitoring» — ознакомительный отрывок электронной книги совершенно бесплатно, а после прочтения отрывка купить полную версию. В некоторых случаях можно слушать аудио, скачать через торрент в формате fb2 и присутствует краткое содержание. Жанр: unrecognised, на английском языке. Описание произведения, (предисловие) а так же отзывы посетителей доступны на портале библиотеки ЛибКат.

- Название:Continuous Emission Monitoring

- Автор:

- Жанр:

- Год:неизвестен

- ISBN:нет данных

- Рейтинг книги:4 / 5. Голосов: 1

-

Избранное:Добавить в избранное

- Отзывы:

-

Ваша оценка:

- 80

- 1

- 2

- 3

- 4

- 5

Continuous Emission Monitoring: краткое содержание, описание и аннотация

Предлагаем к чтению аннотацию, описание, краткое содержание или предисловие (зависит от того, что написал сам автор книги «Continuous Emission Monitoring»). Если вы не нашли необходимую информацию о книге — напишите в комментариях, мы постараемся отыскать её.

The new edition of the only single-volume reference on both the regulatory and technical aspects of U.S. and international continuous emission monitoring (CEM) systems Continuous Emission Monitoring

Continuous Emission Monitoring:

Continuous Emission Monitoring, Third Edition

Continuous Emission Monitoring — читать онлайн ознакомительный отрывок

Ниже представлен текст книги, разбитый по страницам. Система сохранения места последней прочитанной страницы, позволяет с удобством читать онлайн бесплатно книгу «Continuous Emission Monitoring», без необходимости каждый раз заново искать на чём Вы остановились. Поставьте закладку, и сможете в любой момент перейти на страницу, на которой закончили чтение.

Интервал:

Закладка:

A fourth wave of continuous emission monitoring applications came after 2000 with the delayed and piecemeal regulatory development of rules for hazardous air pollutants. The program to control hazardous air pollutant emissions was promulgated in the 1990 Clean Air Act Amendments along with the acid rain program; however, due to the enormity of the task of regulating 187 hazardous air pollutants from 174 source categories, the program was slow to start. It wasn’t until after 2000 that continuous monitoring requirements for air toxics began to come into effect, but the need to develop new and more sophisticated monitoring systems for measuring particulate matter, mercury, and hydrochloric acid was apparent before that time. A new generation of monitoring systems was developed, measuring a wider range of compounds and materials, at ever lower concentrations, by incorporating advanced measurement and miniaturization techniques developed in response to national military and security concerns.

The business of continuous emission monitoring is largely dependent upon environmental regulations and is almost cyclical with the ebb and flow of environmental rule‐making. As new regulatory programs are developed, it is found necessary that a means be provided to keep track of progress or lack of progress. When emission limits are mandated, enforcement programs require a measure of whether emission limits are met or not. Intermittent manual stack testing is clearly not adequate for this purpose, and it has been demonstrated that continuous emission monitoring systems can provide data of sufficient precision and accuracy to support enforcement programs and allowance trading programs. With emission limits becoming ever more stringent and the proper operation of pollution control equipment ever more critical, continuous emission monitoring systems have evolved where they can today, meet the most demanding applications.

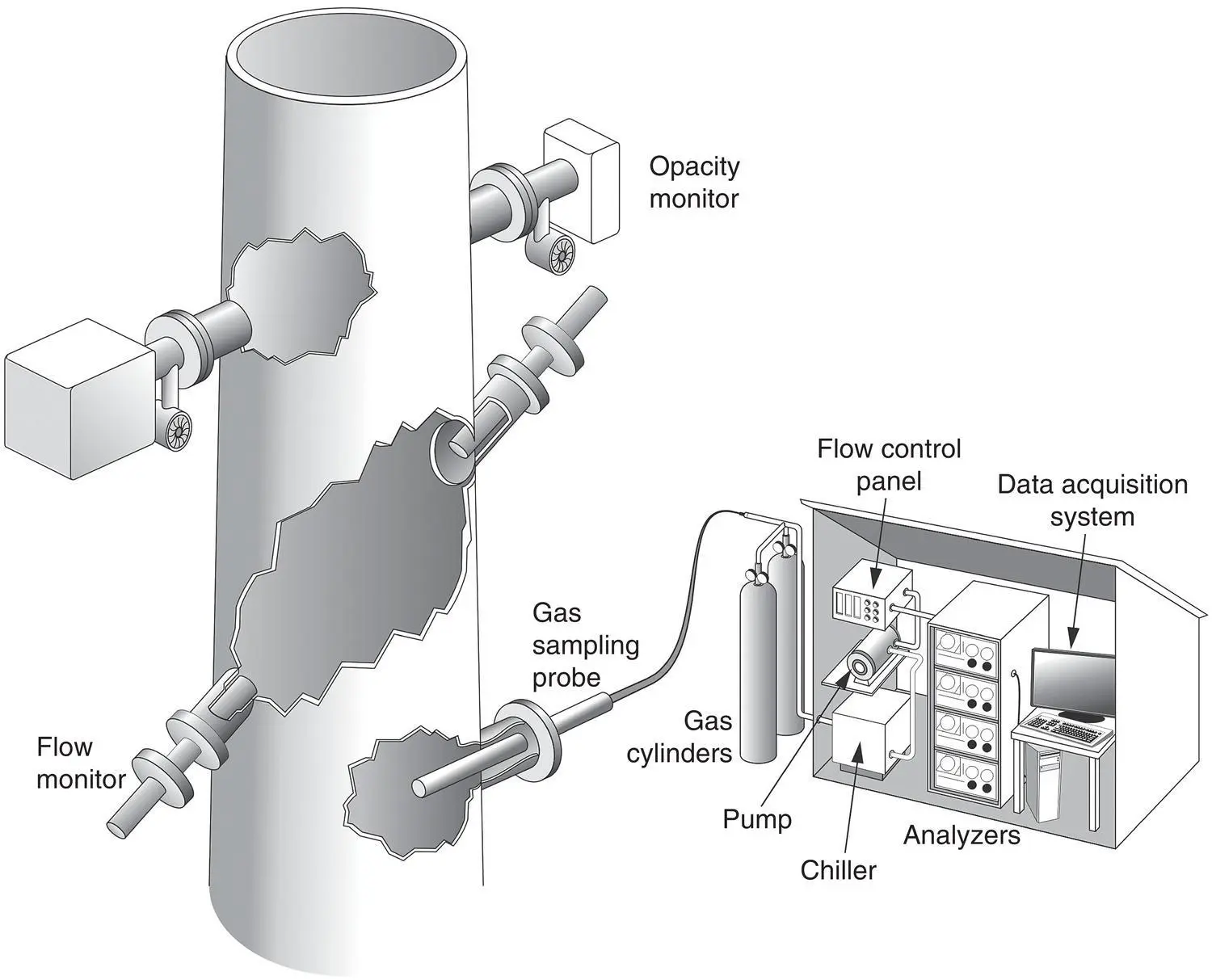

Figure 1‐1 A continuous emission monitoring (CEM) system.

TYPES OF MONITORING SYSTEMS

A CEM system is actually composed of several subsystems: the sampling interface, the gas analyzer(s), and the data acquisition/controller system. The sampling interface is a subsystem that either transports or separates the flue gas from the analyzer. CEM systems are characterized in terms of the design of this interface. In extractive systems, the interface consists of a system that extracts and conditions the gas before entering the analyzer. In in‐situ systems, the interface is simpler, composed of flanges designed to align or support the monitor and blower systems used to minimize interference from particulate matter. The data acquisition/controller subsystem is integral to the proper operation of the total system. The control system controls automatic functions of the system, such as calibration, probe purging, and alarming. The data acquisition system receives the analyzer data, converts it into appropriate units, records it, and provides reports for both internal and external use. Today, CEM data acquisition systems are frequently networked to engineering, corporate, and even agency offices, where the data are used for a variety of operational and management purposes.

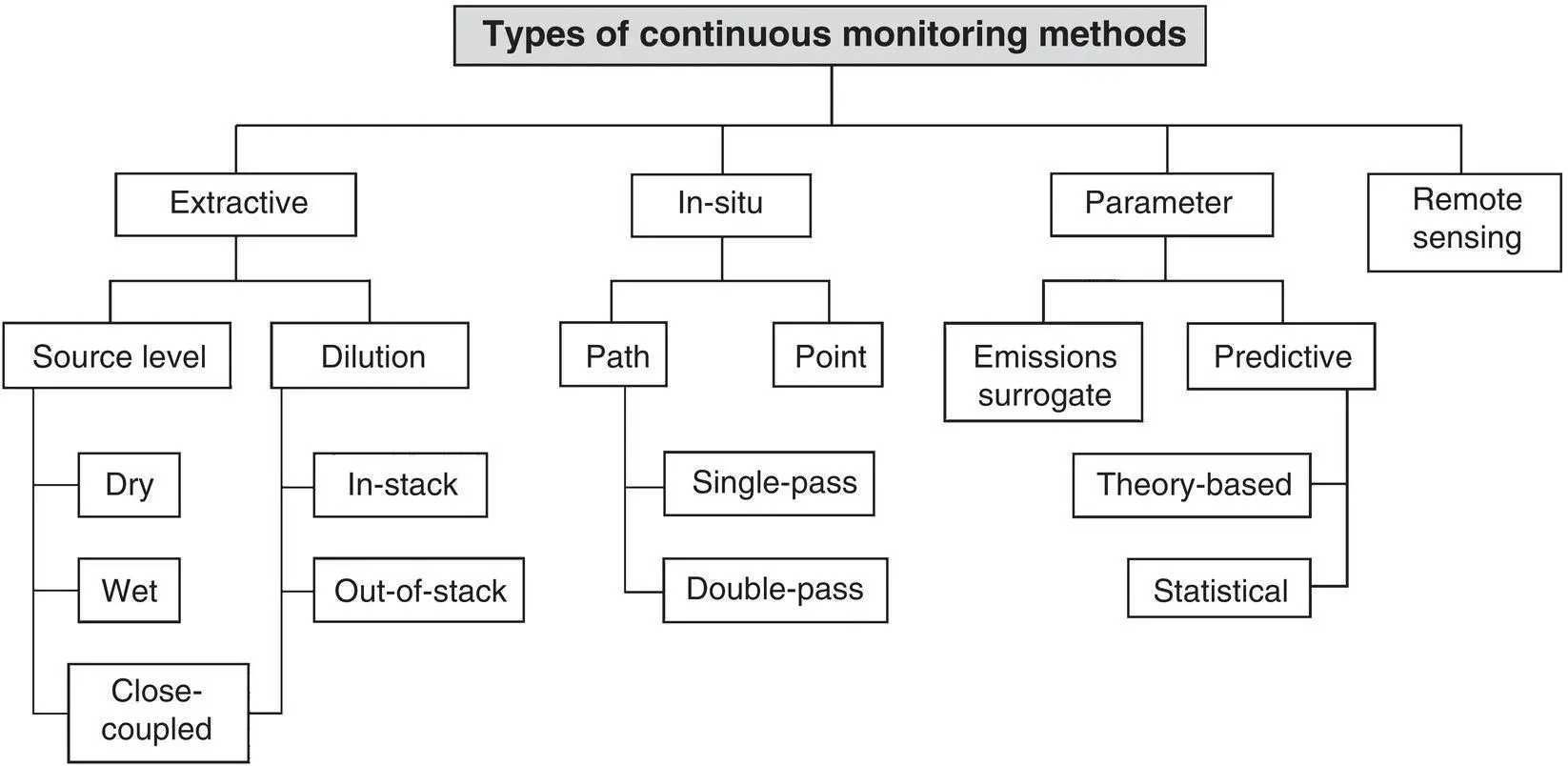

Both extractive and in‐situ systems operate in the source environment and must operate continually under changing stack and ambient conditions. Although this is not necessarily a problem for properly designed and maintained systems, alternative approaches have been sought. One of these approaches, remote sensing, has been applied with limited success, but has not been used widely. Another alternative, the correlation of stack emissions to process parameter data, has led to computerized “predictive emission monitoring systems” or PEMS. These systems have been employed successfully in a number of applications and have considerable potential if used in tandem with extractive or in‐situ monitoring hardware. The monitoring methods discussed earlier are classified in Figure 1‐2and discussed further in the following sections.

Extractive Systems

Extractive gas monitoring systems were the first to be developed for source measurements. In these systems, gas is extracted from a duct or stack and transported to analyzers to measure the pollutant concentrations. Many of the early extractive systems first diluted the gas using rotameters, and then applied ambient air analyzers for measurements. However, frequent problems occurred in maintaining stable dilution ratios, so analyzers were subsequently developed to directly measure the flue gas at source‐level concentrations in the range of 100–1000 ppm or higher. These source‐level extractive systems were quite successful and received their widest application in the 1970s and early 1980s.

Many of the problems associated with the earlier dilution systems have since been eliminated by new techniques developed in the 1980s. The advent of the “dilution probe” made dilution systems viable for source measurements. Dilution systems are now relatively easy to construct and exhibit good performance. They are particularly useful for monitoring water‐soluble gases and provide a platform for the application of a new generation of analyzers that are able to measure part per billion concentration levels.

In order for an instrument to measure gas concentrations, the gas sample must be free of particulate matter. Often, water vapor is removed and the sample is cooled to instrument temperature. This requires the use of valves, pumps, chillers, sample tubing, and other components necessary for gas transport and conditioning. “Hot‐wet” systems, which measure hot gases without water removal, operate continuously at elevated temperatures, eliminating the need for water removal systems. Extractive systems use an umbilical line to transport the flue gas sample from the stack or duct to an analyzer cabinet or temperature‐controlled shelter. This line is heated in source‐level systems where the conditioning system is located in the shelter.

Figure 1‐2 Types of monitoring systems.

Dilution‐extractive systems became popular in the 1990s for determining pollutant mass emission rates at U.S. coal‐fired power plants subject to acid rain cap‐and‐trade regulations. Dilution‐extractive CEM systems measure on a wet basis, an advantage when required to report emissions in units of tons/year or kg/hr. Dilution‐extractive systems are available where the sample dilution takes place in a specially designed in‐stack probe or, alternatively, in a probe box outside of the stack, where a variety of dilution techniques are available. In either case, when the flue gas sample is diluted at the stack, a heated umbilical line is not always needed to transport the diluted sample to a CEM shelter.

Close‐coupled systems are extractive systems where the sample conditioning and analysis are conducted directly on the stack. In these systems, the analyzer is connected directly to the sample probe. These systems avoid sample losses for “sticky” or reactive gases due to gas transport and also reduce system costs by not requiring an umbilical line.

In‐Situ Systems

In‐situ systems consist primarily of an analyzer that employs some type of sensor to measure the gas directly in the stack, or projects light through the stack to make measurements. The opacity monitor and flow monitor illustrated in Figure 1‐1are typical examples of in‐situ analyzers. There are two classifications of in‐situ analyzers: point and path. Point analyzers consist of an electro‐optical or electroanalytical sensor mounted on the end of a probe that is inserted into the stack. The point in‐stack measurement is usually made by a sensor over a distance of only a few centimeters. Path analyzers, on the other hand, measure along a path across the width of the duct or diameter of the stack. In these “cross‐stack” gas analyzers, light is transmitted through the gas, and the interaction of the light with the flue gas is used to obtain a quantitative value of the pollutant concentrations. In single‐pass instruments, light is transmitted from a unit on one side of the stack to a detector on the other side, making only one pass through the stack. In a double‐pass system, light is reflected from a mirror on the opposite side, doubles back on itself, and is detected back at the “transceiver.”

Читать дальшеИнтервал:

Закладка:

Похожие книги на «Continuous Emission Monitoring»

Представляем Вашему вниманию похожие книги на «Continuous Emission Monitoring» списком для выбора. Мы отобрали схожую по названию и смыслу литературу в надежде предоставить читателям больше вариантов отыскать новые, интересные, ещё непрочитанные произведения.

Обсуждение, отзывы о книге «Continuous Emission Monitoring» и просто собственные мнения читателей. Оставьте ваши комментарии, напишите, что Вы думаете о произведении, его смысле или главных героях. Укажите что конкретно понравилось, а что нет, и почему Вы так считаете.