1 Cover

2 Title Page

3 Copyright Page

4 Dedication Page

5 Preface

6 Introduction Part 1: Structural Analysis Part 2: Venting Analysis

7 How to Use This Book

8 Symbols

9 Typical Dust Collection System Checklist

10 Acknowledgments

11 Part 1: Structural Analysis and Design for Reinforcing Dust Handling Systems 1 Design Criteria and General Theory 2 Square/Rectangular Dust Collector Wall, Roof, and Hopper Sections Rectangular Panel Stresses Dust Collector Side and Rear Panels Hopper Panels: Reinforcing Horizontal and Vertical Members Hopper Panels: Using Horizontal Members Only Ribbed Dust Collectors 3 Round/Cylindrical Dust Collectors Ports: (Nozzles) Vessel Head Not Flat 4 Reinforcing Member to Panel Weld Analyses and Port (Nozzle) Weld Analyses Corner Miter Joint Reinforcing Weld Analysis Port (Nozzle) Reinforcing Weld Analyses 5 Access Doors, Hinges, and LatchesAccess Door Hinges and Latches 6 Explosion Vent Ducts, Mill Inlet Air Ducts, Blast Deflectors, and Filter Bag Cage Design Vent Duct Flange Bolt Loading and Stress Hammermill Air Inlet Duct 7 Explosion Vent Duct Weather Covers 8 Dust Collector Stability Wind Force ( F w) Floor or Ground Anchor 9 System Explosion Isolation Pressure Profile 10 Screw Conveyors, Rotary Airlock Valves, and Isolation Valves Rotary Airlock Valves Isolation Valves General 11 Grounding of Systems 12 Housekeeping and General Information General Information Appendix A: Part 1: WorksheetStructural Tubing – Panel Worksheet (Example) Structural Tubing – Panel Worksheet Structural Angle – Panel Worksheet (Example) Structural Angle – Panel Worksheet Structural Channel – Panel Worksheet Reinforcing Rib – Panel Worksheet Detail 1: Panel to Panel Corner Joint Worksheet Detail 2: Panel to Panel Corner Joint Reinforced Worksheet Detail 3: Reinforcing Member Miter Joint Weld Worksheet Detail 4: Square/Rectangular Bolted Flange Worksheet Detail 5: Round Duct Bolted Flange Worksheet

12 Part 2: Explosion Relief Element and Explosion Flowing Pressure Analyses 13 Know Your Process Dust Characteristics 14 Venting Analysis of Dust Handling Systems Square/Rectangular Dust Collector Cylindrical Dust Collector 15 Duct Back Pressure Considerations Duct Back Pressure Correction Summary of the Examples 16 Other Methods of Explosion Pressure Reduction Chemical Suppression System Ten bar Rated Mills Flameless Venting System Appendix B: Part 2: WorksheetDust Collection System Checklist

13 References

14 Index

15 End User License Agreement

1 Chapter 1Table 1.1 Material properties and allowable stresses.Table 1.2 Steel sheet gauges.

2 Chapter 2Table 2.1 Panel edges fixed.Table 2.2 Rib reinforcing section modulus, S c.Table 2.3 Structural angle – panel composite sections.Table 2.4 Rectangular tube – panel composite sections, S c.Table 2.5 Channel – panel composite sections, S c.

3 Chapter 4Table 4.1 Allowable load on welds: intermittent welds occur in pairs.Table 4.2 Structural angle – panel composite sections: I C, Y ′, A p, and W p.Table 4.3 Structural tubing – panel composite sections: I C, Y ′, A p, and W p.Table 4.4 Structural channel – panel composite sections: I C, Y ′, A p, and W p.Table 4.5 Rib – panel composite sections: I C, Y ′, A p, and W p.

4 Chapter 5Table 5.1 Bolt material and 67% yield strength.Table 5.2 Bolt sizes and stress areas.

5 Chapter 13Table 13.1 Explosion characteristics of various dusts.

6 Chapter 14Table 14.1 Conversion factors.

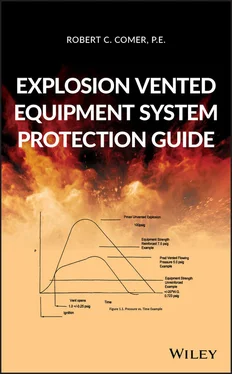

1 Chapter 1Figure 1.1 Pressure versus time example.

2 Chapter 2Figure 2.1 Typical dust collector unreinforced.Figure 2.2 Typical dust collector reinforced.Figure 2.3 Width of loading small panel.Figure 2.4 Reinforcing member loading.Figure 2.5 Actual unsupported panel width.Figure 2.6 Width of loading large panel.Figure 2.7 Cross reinforcing member loadingFigure 2.8 Reinforcing member for Example 2.2, shear and moment diagrams.Figure 2.9 Side and rear panel reinforcing.Figure 2.10 Hopper panel reinforcing members.Figure 2.11 The horizontal reinforcing member.Figure 2.12 Vertical reinforcing member (conservative analysis).Figure 2.13 Hopper panel horizontal members only.Figure 2.14 Panel reinforcing rib loading.Figure 2.15 Panel reinforcing rib.Figure 2.16 Square/rectangular vessel.Figure 2.17 Panel to panel corner joint worksheet.Figure 2.18 Panel to panel corner joint reinforcing worksheet.Figure 2.19 Panel to panel corner joint worksheet.Figure 2.20 Panel to panel corner joint reinforcing worksheet.Figure 2.21 Reinforcing cross member miter joint.Figure 2.22 Bolted flange detail.Figure 2.23 Bolted flange stress.Figure 2.24 Typical dust collector ribbed.Figure 2.25 Panel reinforcing rib loading.Figure 2.26 Panel reinforcing rib.Figure 2.27 Panel reinforcing rib and tube.

3 Chapter 3Figure 3.1 Cylindrical vessel.Figure 3.2 Cylinder and head stresses.Figure 3.3 Reinforcing member 1 loading.Figure 3.4 Reinforcing member 2 loading.Figure 3.5 Reinforcing member 3 loading.Figure 3.6 Reinforcing members summary.Figure 3.7 Rib reinforcing edges.Figure 3.8 Tube reinforcing edges.Figure 3.9 Small nozzle example 1 on a flat head.Figure 3.10 Small nozzle example 2 on a curved surface.Figure 3.11 Ellipsoidal head.Figure 3.12 Torispherical head.

4 Chapter 4Figure 4.1 Weld spacing. F a, allowable load per pair of fillet welds (lbs, T...Figure 4.2 Head reinforcing rib member 1.Figure 4.3 Head reinforcing member 3.Figure 4.4 Head reinforcing angle member 3.

5 Chapter 5Figure 5.1 Panel reinforcing loading.Figure 5.2 Main reinforcing member for access door.Figure 5.3 Weld spacing.Figure 5.4 Access door latch (bolted).Figure 5.5 Access door hinge (bolted).Figure 5.6 Access door toggle clamp.Figure 5.7 Hinge/latch reinforcing tube.Figure 5.8 Eyebolt bracket.Figure 5.9 Tear out analysis.Figure 5.10 Clevis pin.Figure 5.11 Bending analysis.

6 Chapter 6Figure 6.1 Explosion vent duct: roof.Figure 6.2 Explosion vent duct: wall.Figure 6.3 Blast deflector.Figure 6.4 Explosion vent duct – reinforcing.Figure 6.5 Blast deflector: reinforcing.Figure 6.6 Gasketed duct flange bolt load diagram.Figure 6.7 Square vent duct with no bend at end of duct.Figure 6.8 Square vent duct with bend at end of duct.Figure 6.9 Square vent duct with 90° bend at end of duct.Figure 6.10 Square vent duct bolt spacing example.Figure 6.11 Vent duct flange detail.Figure 6.12 Flange stress with no bend.Figure 6.13 Flange stress with a 45° bend at the end of the duct (for the sq...Figure 6.14 Flange stress with a 45° bend (for the square bolted flange, ref...Figure 6.15 Flange stress with a 90° bend at the end of the duct (for the sq...Figure 6.16 Flange stress with a 90° bend (for the square bolted flange, ref...Figure 6.17 Round vent straight duct with no bend at end of duct.Figure 6.18 Round vent straight duct with 45° bend at end of duct.Figure 6.19 Round vent straight duct with 90° bend at end of duct.Figure 6.20 Round vent duct bolted flange 16 blots example.Figure 6.21 Round flange stress with a 45° bend at the end of the duct (for ...Figure 6.22 Flange stress with a 45° bend (for the round flange Refer to Fig...Figure 6.23 Flange stress for the round flange with 90° bend at end of duct ...Figure 6.24 Flange stress (for the round flange refer to Figures 6.19 and 6....Figure 6.25 Flange stress (for the round flange refer to Figures 6.19 and 6....Figure 6.26 Hammermill air inlet duct.Figure 6.27 Filter bag cage detail.Figure 6.28 Wall penetration vent duct non‐loss‐in‐weight vessel.Figure 6.29 Wall penetration vent duct loss‐in‐weight vessel.Figure 6.30 Vent duct flange detail.Figure 6.31 Bird screen detail.

Читать дальше