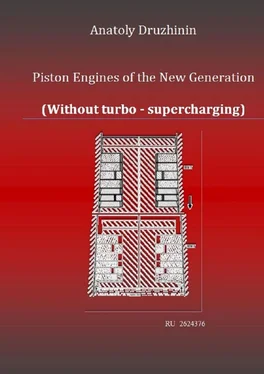

Piston Engines of the New Generation (Without turbo – supercharging)

Anatoly Matveevich Druzhinin

Editor Фарида Бинятулловна Мирзамова

Translator Анастасия Сергеевна Агафонова

© Anatoly Matveevich Druzhinin, 2018

© Анастасия Сергеевна Агафонова, translation, 2018

ISBN 978-5-4493-6090-8

Created with Ridero smart publishing system

The book gives an analysis of mistakes in the generally accepted calculations of piston rings, carried out without taking into account the influence of physical laws on the operation of rings (gas dynamics, hydraulics and thermodynamics). Based on the analysis, the formula of determining the piston ring height was initially obtained. Essentially new designs of “piston devices”have been developed, in which the sealing and oil-removal piston rings are located in one piston bore located at the top of the piston. Integral construction of the piston deviceincreases the efficiency of the engine, its power and life, reduces fuel and engine oil consumption, improves the environmental characteristics of the engine and eliminates the need for turbocharging.

The book presents updated and revised information on previous editions, adapted to the features of powerful and heavy-duty engines and compressors. The temperature changes in the shape and dimensions of the cylinder, a new piston rings combined into one contraction reduce to a minimum mechanical friction losses, to increase the engine power and resource, to reduce fuel consumption, to increase oil replacement terms, to improve ecological indicators of the engines. The design excludes application of a turbo-supercharging. The modernization concerns the cylinder-piston group of the engines or compressors, and it does not require fundamental changes in technological processes. The conditions have been created for the use of water in engine processes, and the increased competitive advantages of two-stroke engines was justified.

The book will be useful for the engineering and technical workers of motor-building enterprises, for scientists and specialists on piston devices, for students in higher and secondary educational establishments, for students of faculties and Institutes of advanced training, for driving schools when studying the design of the engines.

Anatoly Druzhinin Matveyevich, born in 1935, Candidate of Technical Sciences, Associate Professor of the Kazan Scientific Technical University named after A. N. Tupolev. Professional technologist for aviation, rocket engines and internal combustion engines. The problem of increasing the internal combustion engine efficiency has been exploring for more than 30 years, the first invention: Piston seal for ICE, Authors’ certificate, SU, No. 1388572, received in 1986. Inventions: Cylinder piston group of internal combustion engines, patents No. 2624376, 2017 and No. 2,651,694,2018 include all the innovations developed by the author. Totally there are 36 inventions and 6 patents for utility models.

The results of the research have been published in 8 issues of the scientific and technical journal “Russian Engineering Research”, translated into English and distributed all over the world. Two books have been published: Cylinder-Piston Group of the Engines and Compressors: 100% of Innovative Elements CPG/Anatoly Druzhinin. – [B. M.]: Publishing decisions, 2016. -238 C. and Modernization of the Internal Combustion Engines: Cylinder-piston Group of the New Generation, M.: Infra-Engineering, 2017. -150 C.

Druzhinin was awarded a Certificate “For the Best Innovative Idea” A new piston seals for the internal combustion engines” of the Republican competition “50 Best Innovation Ideas of the Republic of the Tatarstan”, 2006.

The book “How Make the Engine Better. New Piston Rings” is a participant of the Moscow International Book Fair, 2017.

“Theory without practice is dead”

Practice is poor without theory. The harmony of theory and practice is the way to perfection”

The book presents a new edition of earlier published works of the author. The Russian name of this book is inherited from the article “How Make the Engine Better?” which was published in a very authoritative magazine “Russian Engineering Research”. The magazine is included in the list of approved by VAC RF for the publication of works of applicants of academic degrees [1]. The journal is translated into English, reprinted and distributed worldwide by Allerton Press (USA).

It is necessary that the information must be interesting for theorists and practitioners, specialists of the internal combustion engines, to publish an article in such an authoritative journal. Such grounds were. So the series of articles were published, not only in this journal but also in the profile journal “Automotive Industry”.

The book represents a new revision of another author’s book “Cylinder-piston Group of Engines and Compressors: 100% of the Innovative CPG Elements [3]. The contents of the book complement with new information, on inventions was received, the most significant practical proposals, designs, and justifications for their technological realization was reflected.

As a result of many years of searching for the reasons for the low efficiency of the engine, the specialist technologist found a fundamental errorof the designers in the most important part of the design of the internal combustion engine (ICE) in cylinder-piston group (CPG).

This mistake claimed a scientific and technical sensation, because for the first time one of the main evidence of this event was published- the gas dynamics schemeof the piston compression ring. Which was opened a new direction in the design of the CPG elements for piston machines of various sizes and purposes.

The gasdynamic scheme and, based on its analysis, the formula of piston ring height determining, made it possible to supplement with the new data scientific and technical and educational literature devoted to solving problems of increasing the efficiency of the cylinder piston group and the engine itself.

In this publication, the attention of specialists is focused on the behaviour of gas dynamics at different cycles of the engine operating cycle. There is a really perspective to starting to improve the engine, in the designing and production process and in use during scheduled or unscheduled repairs.

More than 10 years passed, but the interest in the scientific community, has not appeared. The magazine articles and the textbooks published by the author remain unused. The mystery that the author had to decide and he had to believe he decided it. All this is described in more detail in the proposed edition.

In recent years, the human attitude towards scientific and technological progress has fundamentally changed. The problem of increasing the efficiency of lCE, the need “make the engine better” may be most revealing.

The author had to face with some problems of which did not help to solve the problem of improving the engine efficiency. Some approve principle changes in design others do not. We’ll try to understand these contradictions.

Start from the beginning of the product creation, with designers. Designers often develop a more complex design, forgetting that “simplicity is the sister of talent” and “the best is the enemy of the good”. In our work there is a concrete example, the “turbo-supercharging” of engines which is actively advertised and universally applied. The inexpediency of using the “supercharging”, the author tried to explain in his work [2].

Читать дальше