Each tile on Columbia was of a unique size and shape. We had all that information in our databases before the accident. Engineers tried using a modified version of KSC’s EMAP software application—designed to track the status of waterproofing the shuttle’s tiles in the Orbiter Processing Facility—to construct a virtual three-dimensional model of the recovered tiles and where they came from on the vehicle. While it showed which tiles had been recovered and which had not, it was not useful for seeing patterns in how the recovered tiles were damaged. We needed to use the tiles themselves to show us what happened.

In late March, we constructed a “tile table”—a platform with a full-size dimensional drawing of the 2,800 unique tiles on the left wing. As each piece of left wing tile came back, engineers identified it—sometimes based on a few millimeters of thickness—and placed it in the appropriate location on the tile table.

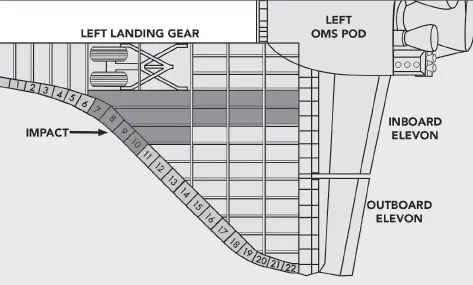

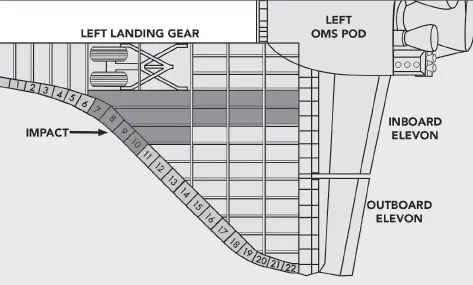

The tiles laid out on the table told a compelling story of the left wing’s disintegration. The carrier panel tiles, which were the closeout between the panels on the leading edge of the wing and the tiles covering the rest of the wing, clearly showed where the wing breach occurred. The carrier panel tiles behind the inboard leading edge panels 1 through 8 appeared relatively similar. The tiles behind panel 9, though, showed evidence of high heating. Their surfaces were slumped, and their undersides were coated with metallic deposits from interior portions of the wing.

From the burn patterns on the other tiles, we saw that hot plasma had entered the wing at high velocity—thousands of miles per hour—and pressurized the wing cavity. The pressure created vents, which blew the superheated plasma and molten metal out of the upper and lower surfaces of the wing. The materials blowing out through the lower vent formed an obvious burn pattern along the underside of the wing.

As the plasma stream cut through the leading edge spar, it heated the wing and caused the adhesive that held the tiles onto the wing surface to fail. Those tiles peeled off the wing. They were designed to take heat from their outside surfaces, not from the side where they were glued onto corresponding felt pads covering the ship’s wings. The degraded glue on the underside of those tiles clearly demonstrated that the wing was baking from the inside out. [20] NASA reconstruction video.

The heavily damaged tiles on the left OMS pod (at the left rear of the shuttle) and the left side of the vertical stabilizer also provided clear evidence that the insides of the left wing were melting. The airflow around the vehicle during reentry put the OMS pod and tail directly downstream of the wing. As the interior components of the left wing melted and burned, those materials were deposited on and heavily pitted the left OMS pod and left side of the tail. The right side of the tail and the right OMS pod exhibited none of that kind of damage. The right wing had therefore not melted prior to the orbiter’s breakup.

Plotting the tile recovery locations on a map also supported the theory about the location of the breach in the wing. The tiles found farthest west in the debris field all came from the left wing, in the areas behind leading edge panels 8 and 9. Many of these tiles had brown streaks on them—Inconel metal from the melted leading edge attachment fittings. [21] CAIB Report , 75.

We also needed to find out what happened to the leading edge of Columbia ’s left wing. Many pieces of the reinforced carbon-carbon (RCC) leading edge of the shuttle’s wings came back from the field, in sizes ranging from larger than one square foot to smaller than a thumbnail. Boeing’s Mike Gordon and NASA structures engineer Lyle Davis spent long hours using micrometers to study the thickness of each tiny piece. They determined which wing and which RCC panel they came from and how they fit together. It was painstaking work. Eventually, the leading edges of both wings began to take shape.

Since the leading edge panels are U-shaped in cross section and up to several feet long, it was difficult to fit them together meaningfully on a two-dimensional grid. First, the team tried tacking the pieces to Styrofoam shaped like the wing’s leading edge. This proved unsatisfactory, because the backsides of the RCC panels were not visible. It was impossible to examine the panels in relation to the pieces of support structure that were behind them on the shuttle’s wing. In April, KSC’s shops fashioned three-dimensional frames made out of clear polycarbonate to hold the pieces of RCC and their supporting attachment fittings in their correct orientation. These frames enabled investigators to look at the reconstructed leading edge components from all sides.

As with the tile tables, the RCC panels told a compelling visual story about the accident. Panels 1 through 7, on the inboard side of the wing, were fractured and broken from forces after the shuttle disintegrated. Globs of aluminum and other metals were spattered along their inner surfaces. The metallic attachment fittings that held the RCC to the wing were still partially intact.

At panels 8 and 9, no metallic fittings were found. The support structure here was made of stainless steel, which melts at 2,500°F—a much higher temperature than the aluminum components in other areas of the wing. Heavy slag buildup inside the RCC panels implied that the leading edge spar behind those panels melted and then was deposited as molten metal onto the surfaces of the panels. The edges of the retrieved pieces of RCC were heavily eroded and knife-edged—signs that plasma acting as a blowtorch at over 3,000°F was applied at high pressure to the panels over a prolonged period of time. This was the only place on the wing where this pattern was observed.

From panels 10 outward, more of the metallic fittings were found, and there was less slag and no erosion.

Materials scientists analyzed cross sections of the slag deposits inside the left wing panels to determine what materials they were made of and how the deposits were laid down. There were several layers of material, which told the story of the wing’s failure in time sequence. As more of the wing structure melted, the different types of metals from various parts of the wing were deposited in layers on top of the material already laid down on the inside of the panels. [22] CAIB Report , 76.

The location of the debris on the ground provided yet more evidence of how the shuttle came apart. Wreckage from the wings was not distributed randomly across East Texas. For example, the leading edge components from the middle to the tip of the left wing (panels 8 to 22) were found in the farthest west part of the debris field, between Dallas and Palestine. The leading edge pieces from the part of the left wing closest to the orbiter body (panels 1 to 7) came down between Palestine and Nacogdoches. The right wing leading edge pieces were the farthest east, scattered between Palestine and Hemphill. This provided evidence that the left wing failed before the right wing, the most likely failure point being near RCC panel 8 or 9. [23] CAIB Report , 75.

By late April, the story told by the debris was inescapable. The breach in the left wing was clearly in the wing’s leading edge, at panel 8 or 9.

The data team and debris team both concluded that a breach in Columbia ’s left wing near RCC panel 8 or 9 allowed plasma to enter the wing. Flowing at several thousand miles per hour and with a temperature well in excess of 3,000°F, the plasma acted like a blowtorch and melted much of the wing’s support structure in the shaded area of this diagram.

On May 1, NASA announced that only one single failure scenario would explain all of the evidence contained in the debris, the OEX recorder, the telemetry received in Houston, and the videos provided by the public and other sources. Something—most likely the collision with the foam from the external tank—caused a breach in the leading edge of the left wing. This breach allowed plasma to penetrate the wing and erode it from the inside during the reentry. Whether the foam actually penetrated the leading edge—or if it pushed spacers apart and created a gap in the panels—will never be known.

Читать дальше