We divided our duties, with me as the “up and out” manager—dealing with the reconstruction effort’s interfaces to management, the CAIB, the press, congressional visitors and other VIPs, and other NASA centers—and Altemus leading the “down and in” day-to-day operations. We knew each other well, having worked together for many years. We made a strong leadership team with complementary skills.

—

The Reusable Launch Vehicle hangar at the southeast end of the Shuttle Landing Facility was only being used for storage in early 2003. It was the perfect size, secure, and convenient. Although it was on NASA property, the state of Florida owned the hangar. We quickly secured a short-term lease as soon as we got the “Go” to stage the reconstruction at Kennedy.

Getting everything set up in less than two weeks, before the first truckloads of debris were due to arrive, was not going to be an easy task. The hangar’s leaky roof needed to be fixed. Processes for receiving, decontaminating, categorizing, and cataloging the debris had to be developed. Someone had to build an area for reconstructing the crew module. Much to Altemus’s relief, KSC director Roy Bridges promised him the unconditional, immediate support of all of KSC’s organizations for whatever he needed to ensure the reconstruction happened smoothly. Altemus would not have to contend with any bureaucratic hassles.

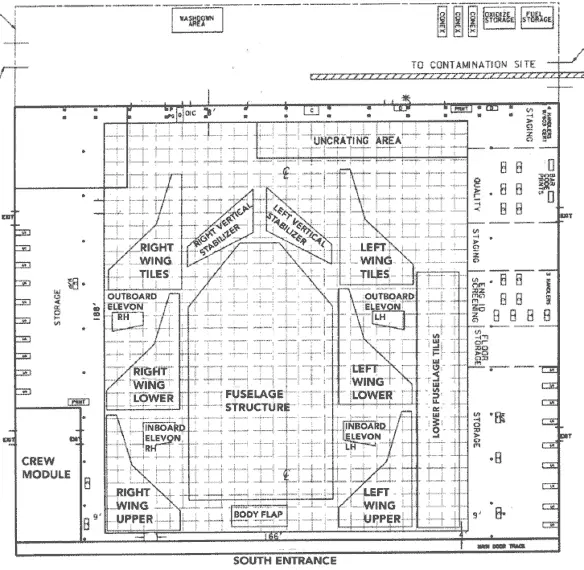

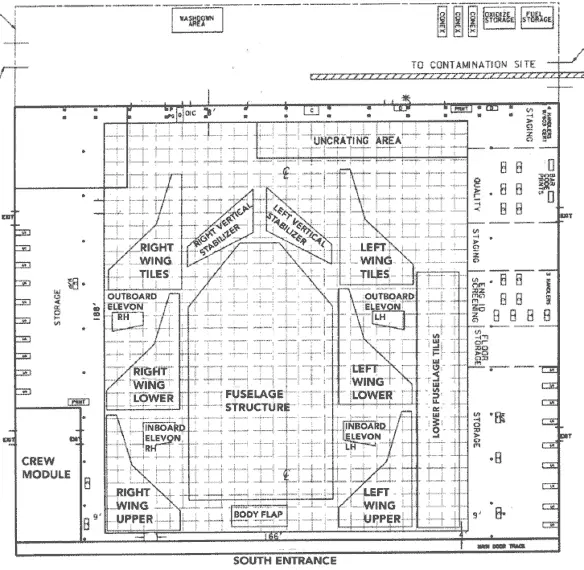

The technical term for the process the NTSB proposed was “reconstruction,” but this was not going to be an attempt to rebuild the ship from her wreckage. Rather, we would lay out the recovered debris on a floor plan representing the shuttle peeled open onto a two-dimensional grid, with the shuttle’s entire outer surface and the wing structures facing upward. By placing the recovered pieces of the shuttle next to one another, as they would have been on the ship, investigators could look for patterns in the debris that might indicate how Columbia was damaged and came apart.

Under NTSB’s guidance, NASA and Boeing Air Safety used yellow tape to lay out a dimensioned grid on the hangar floor, with a blue tape outline of the shuttle’s sections superimposed over it. The NTSB suggested that the outline and grid be 10 percent larger than the actual shuttle. Additionally, the major component areas were separated from each other by about three feet. This would provide room for people to walk around between structures and examine the debris from all angles. The blue tape outline was oriented as if the shuttle had been pulled into the hangar nose first. From there, the outline was drawn as if the shuttle was turned belly side up and splayed out into two dimensions. Each wing was outlined in three separate sections: lower surface tiles, lower surface structure, and upper surface tiles. The idea was that when enough debris was available, placing the lower surface tiles over the lower surface structure would enable engineers to study those components in contact with one another. [1] Interview with Steve Altemus.

Laying out the shuttle on the grid made it easy to see patterns—burns, cracks, stress marks, and the like—in the pieces of the orbiter structure. Those could hint at the state of the vehicle when it broke up. Items from the external surfaces were to be placed on the grid. All materials from the crew module—the compartment in which the astronauts were sitting for launch and landing—would be reconstructed in three dimensions inside a walled-off area with controlled access. Debris from the shuttle’s internal systems—wiring, plumbing, avionics, and so forth, as well as materials from the modules in the payload bay—would go onto “bread racks” along the walls of the hangar. These items were thought not to have contributed to the accident, so they were segregated from the structural debris but readily accessible if necessary. Also lining the hangar walls were workstations for the various engineering disciplines to examine pieces of debris as they arrived from Barksdale.

We set up a separate decontamination site outside of the hangar to protect its workers from potentially hazardous materials. It was possible that some debris might arrive from Texas still contaminated with hypergolic fuels. Pyrotechnic charges might also be attached to some of the wreckage, and these would need to be handled off-site. There was a remote possibility of exposure to biological hazards, either from experiments on the Spacehab module or even from human remains that might have inadvertently made their way back to Florida in the debris. Fortunately, this did not turn out to be an issue, but we needed to have a process established for any contingency.

The NTSB suggested the personnel receiving the debris make a rough hand sketch of the appearance of every item as it arrived. Technicians could also write notes to be filed with the sketches. “That process quickly went out the window, as soon as the trucks started arriving,” Altemus said. Neither NASA nor the NTSB had anticipated we’d recover eighty-four thousand pieces of debris—and most of them would be the size of a nickel. Sketching every item was simply too much work. However, we did photograph and bar code every item received—a level of detail far beyond that in typical NTSB investigations.

With the Columbia Accident Investigation Board’s concurrence, we eventually opened up a second location in an equipment hangar adjacent to the Apollo Saturn V Visitors Center across the road from the Shuttle Landing Facility. This building held friable materials that posed a health hazard because of their microscopic fibers. Some of the items placed in this building were Kevlar-wrapped pressurized tanks and pieces of the payload bay doors.

—

KSC engineers and technicians were eager to work in the hangar. The people who had tended Columbia over the years desperately wanted to help out with the accident investigation in some way. Many of them had volunteered to be deployed to East Texas to help in the search, but for one reason or another, their management had told them that it might not be the best use of their talents. Despondent over the loss of the shuttle, they were frustrated about the lack of opportunities to do something “useful” in the aftermath to take their minds off their grief. Working in the reconstruction hangar was not going to be an easy task. However, it would be a welcome chance for people with specialized knowledge of the shuttle’s systems to use their talents to solve the mystery of what doomed Columbia and her crew.

Orbiter Project Office head Ralph Roe asked Jon Cowart to be the NASA engineering lead from Houston for the reconstruction. Warren “Woody” Woodworth was designated as the chief Columbia reconstruction engineer for United Space Alliance (USA). Jim Comer helped Steve Altemus set up the hangar and then became the head of operations at the hangar for USA, overseeing about three hundred contractors in the reconstruction.

The Astronaut Office assigned Pam Melroy to manage the crew module reconstruction, because she was the lead “Cape Crusader”—the astronauts assigned to work on shuttle issues at KSC. Melroy and her colleague Marsha Ivins alternated workweeks in the hangar, until Ivins moved on to other duties about a month after the accident. Melroy and her staff of six people would have the unenviable task of examining what was left of the crew module and the equipment used by the astronauts. Two of her key assistants were John Biegert and Robert Hanley.

Biegert, a long-term member of the flight crew systems engineering group from Houston, supervised the teams that loaded all of the crew equipment, lockers, food, EVA suits, experiments, and other items—five thousand to seven thousand pieces of equipment and materials altogether—into the crew module in the ten days prior to Columbia ’s launch. He and his teams knew where every item should have been stowed when Columbia ’s crew prepared the ship for landing.

Читать дальше